Hydraulic control system of powdered coal forming machine

A technology of hydraulic control system and forming machine, which is applied in the direction of presses and manufacturing tools, which can solve the problems of low degree of automation, high energy consumption, and poor forming of pulverized coal, so as to reduce product production energy consumption, improve production efficiency, and improve The effect of business benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

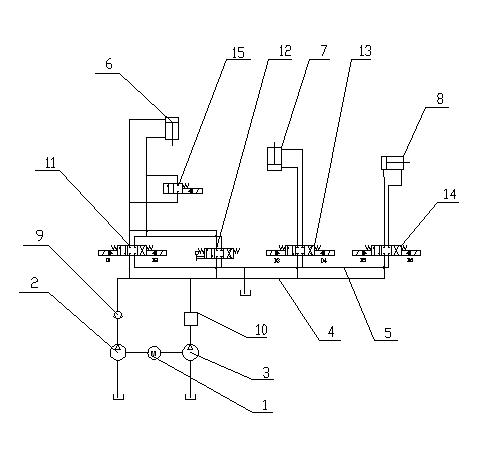

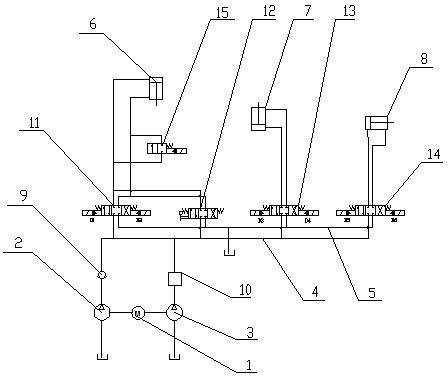

[0012] like figure 1 As shown in the figure, a hydraulic control system of a pulverized coal forming machine is mainly composed of a motor 1, a variable vane pump 2, a variable piston pump 3, a forming cylinder 6 and a die cylinder 7 which are respectively connected with the oil inlet pipeline 4 and the oil return pipeline 5. It is formed with the feeding cylinder 8. The motor 1 controls the variable vane pump 2 and the variable plunger pump 3 in parallel with each other at the same time. Connected with the oil inlet pipeline 4, a three-position four-way solenoid valve I11 and a three-position four-way manual valve 12 are arranged in parallel between the oil inlet line 4 and the molding cylinder 6, and a three-position four-way manual valve 12 is arranged between the oil inlet pipeline 4 and the mold cylinder 7. The four-way solenoid valve II13 is provided with a three-position four-way solenoid valve III14 between the oil inlet pipeline 4 and the feeding cylinder 8, and a two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com