A gas generating device

A technology of gas generation and gas, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as uneven gas outlet temperature, long ignition delay time, and shorten ignition delay, so as to improve work ability and work reliability , Solve the effect of short ignition delay time and shorten ignition delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

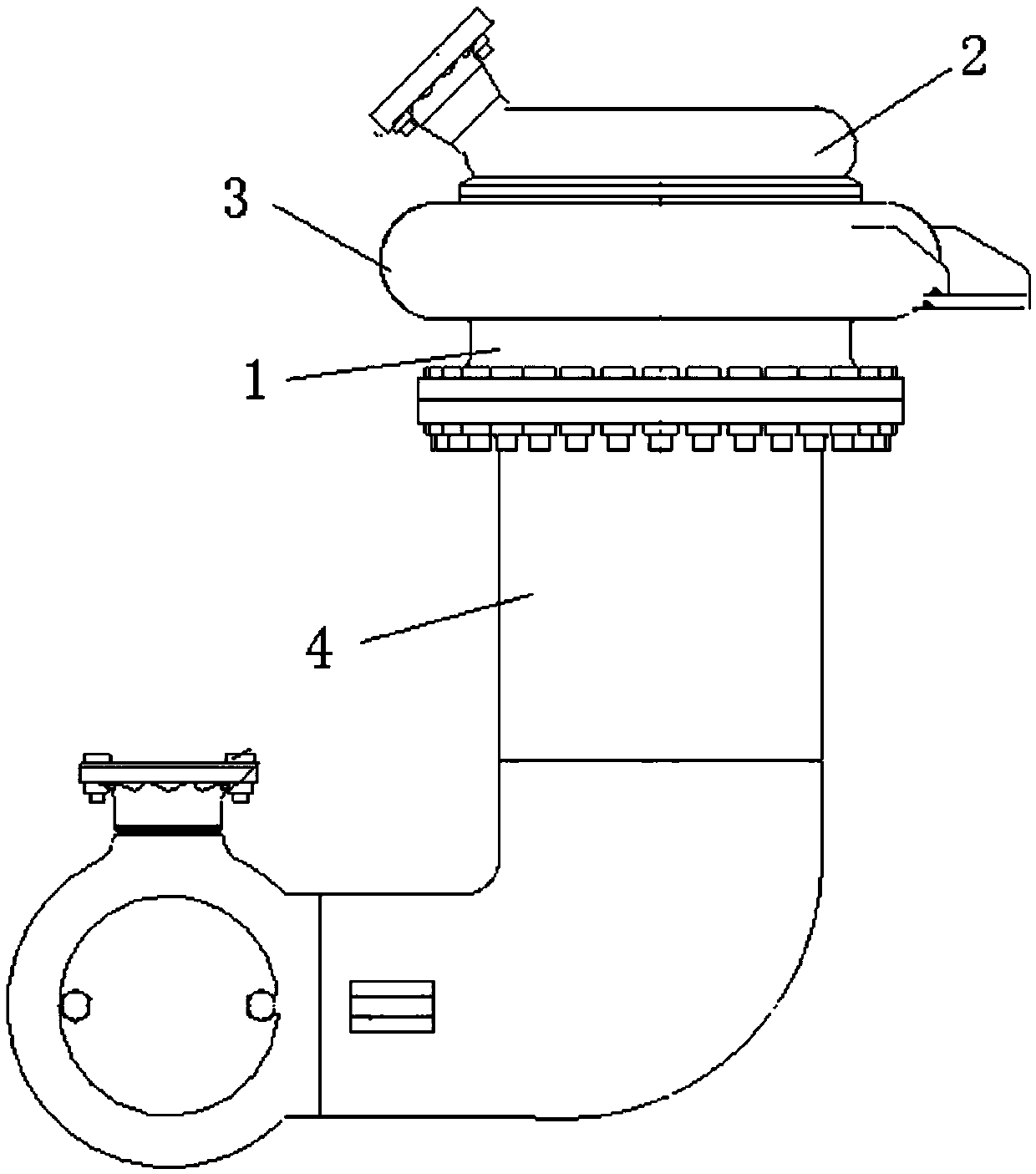

[0017] Such as figure 1 As shown, a gas generating device includes: an injector 1, an oxidant collector 2, a fuel collector 3, and a body 4; wherein, the injector 1, the oxidant collector 2, and the fuel collector 3 are all welded, It is connected with the body through the flange. The oxidant collector 2 and the fuel collector 3 are installed on the injector 1 .

[0018] During the working process, the oxidant and fuel enter the injector 1 through the annular oxidant collector 2 and the fuel collector 3 respectively, and then atomize through the double coaxial nozzle 5 and the coaxial direct-flow nozzle 6 in the injector 1 After combustion, the products of combustion enter the body 4 .

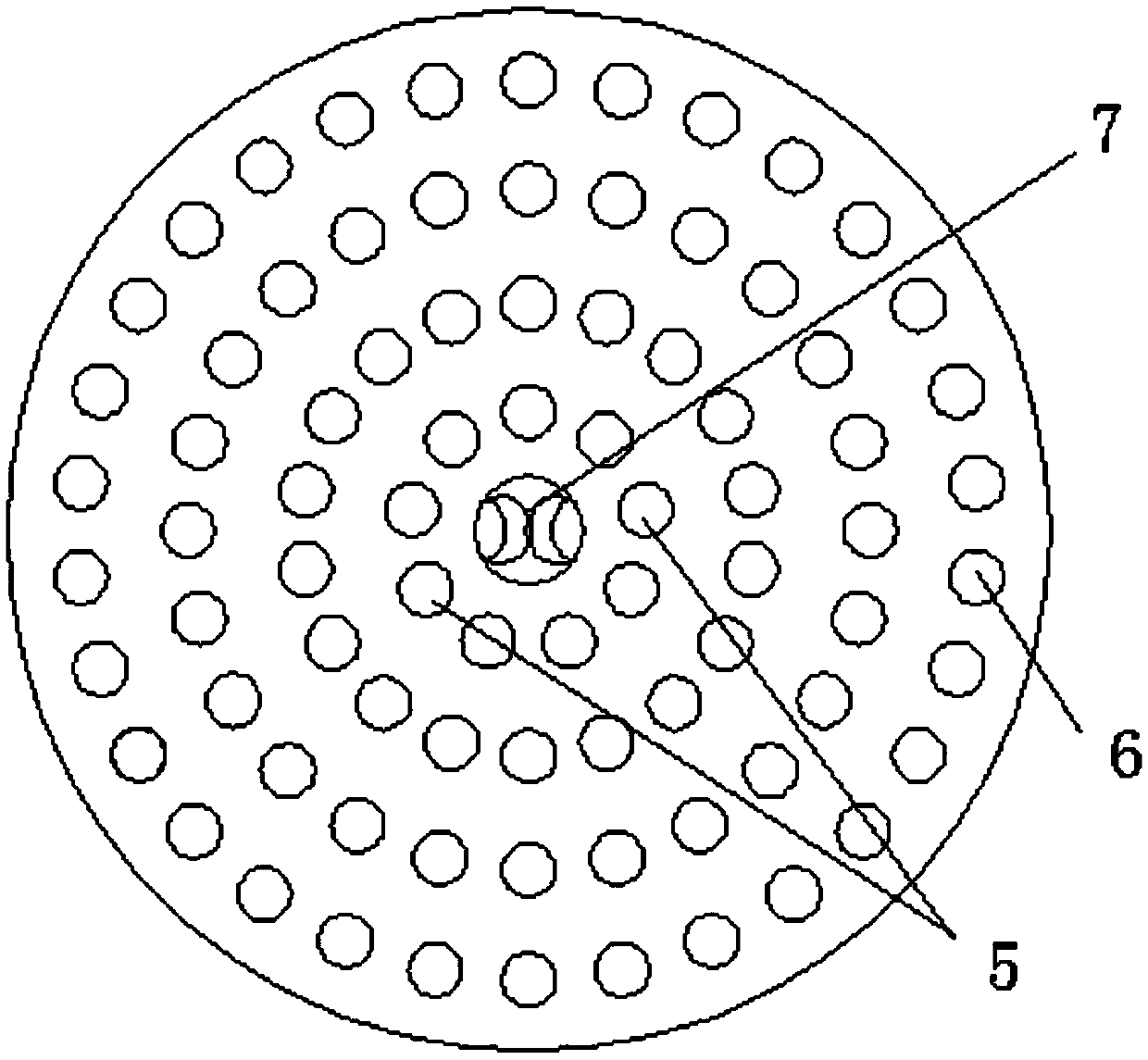

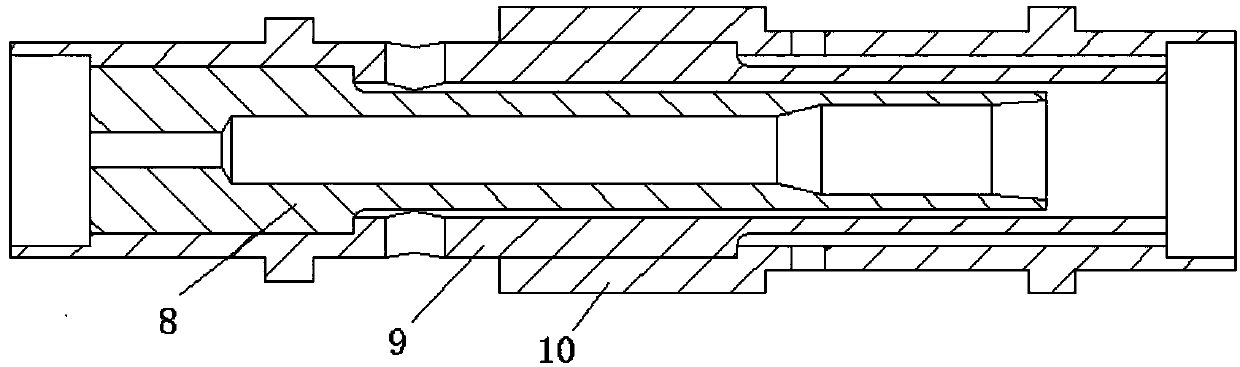

[0019] Injector 1 structure such as figure 2 As shown, it consists of double coaxial nozzles 5, coaxial direct-flow nozzles 6 and flame diffusion tubes 7. Arrange two double-coaxial nozzles 5 near the flame diffusion pipe 7, the angle between the center of the installation hole of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com