Miniature gas-liquid dual-purpose high-energy igniter

An igniter, gas-liquid technology, applied in machines/engines, jet propulsion devices, gas turbine devices, etc., can solve problems such as difficulty in applying small turbine engine ramjets, lack of thermal protection capabilities on walls, and ignition failures of power devices, to ensure The effect of atomization, prolongation of residence time, and improvement of ignition success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

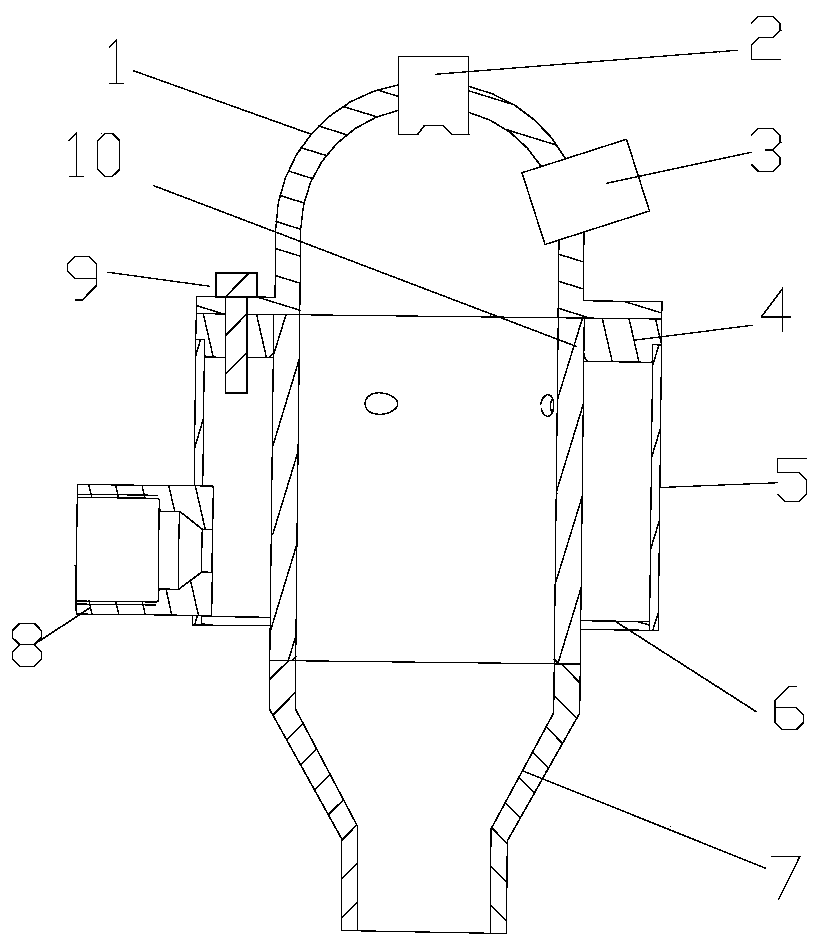

[0026] Such as figure 1 As shown, the present invention provides a miniature gas-liquid dual-purpose high-energy igniter that can be used in turbine engines and ramjet engines, including an upper shell 1 , a lower shell and a tapered section 7 .

[0027] The profile of the upper shell 1 is a combination structure of semi-ellipse, semi-circle, semi-ellipse and rectangle, one of the combination structures of semi-circle and rectangle, and the thickness of the upper shell 1 is in the range of 3-7mm;

[0028] The lower shell is composed of an upper end wall 4, an outer shell 5, a lower end wall 6, and an inner wall 10, and encloses a ring cavity as a gas collection cavity, and the four parts are connected by welding. On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com