Method, device and system for preventing condensation of power component

A power component and anti-condensation technology, which is applied in the direction of condensation prevention, heating and ventilation control system, heating and ventilation safety system, etc., can solve the problem that the anti-condensation and heat dissipation of power components cannot be realized synchronously, and guarantees Reliability, the effect of preventing excessive stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

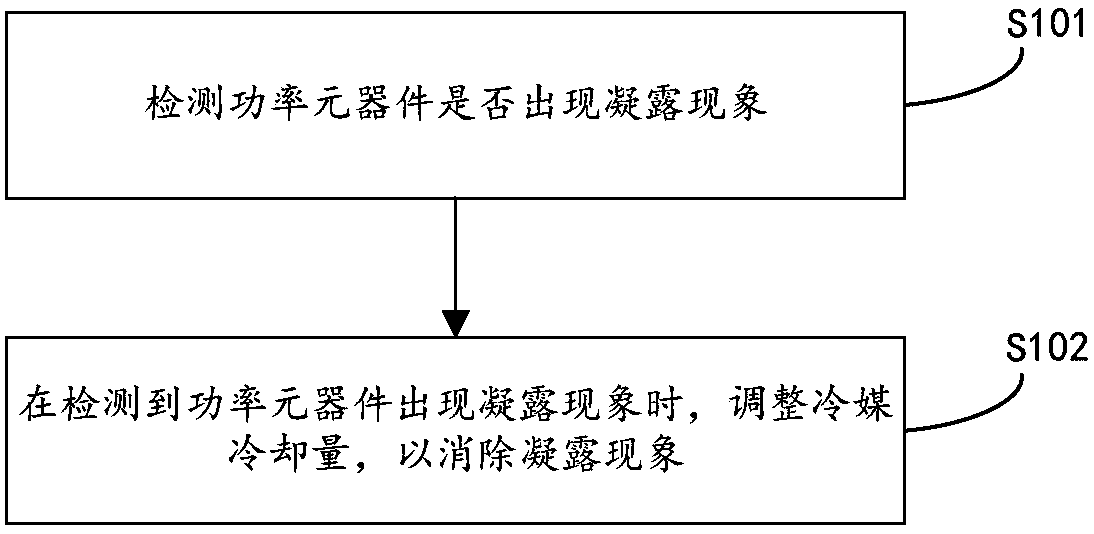

[0030] figure 1 It is a flow chart of the anti-condensation method for power components according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps (step S101-step S102):

[0031] Step S101, detecting whether condensation occurs in the power components;

[0032] Step S102, when it is detected that condensation occurs in the power components, the cooling amount of the refrigerant is adjusted to eliminate the condensation.

[0033] In this embodiment, by detecting whether there is condensation in the power components, the cooling amount of the refrigerant is controlled, and the heat dissipation of the power components can be realized simultaneously, so as to prevent excessive stress and strain of the power components, and problems such as premature aging of the main board caused by alternation of cold and heat; and It can realize no condensation and ensure the reliability of the unit; it can also meet the capacity req...

Embodiment 2

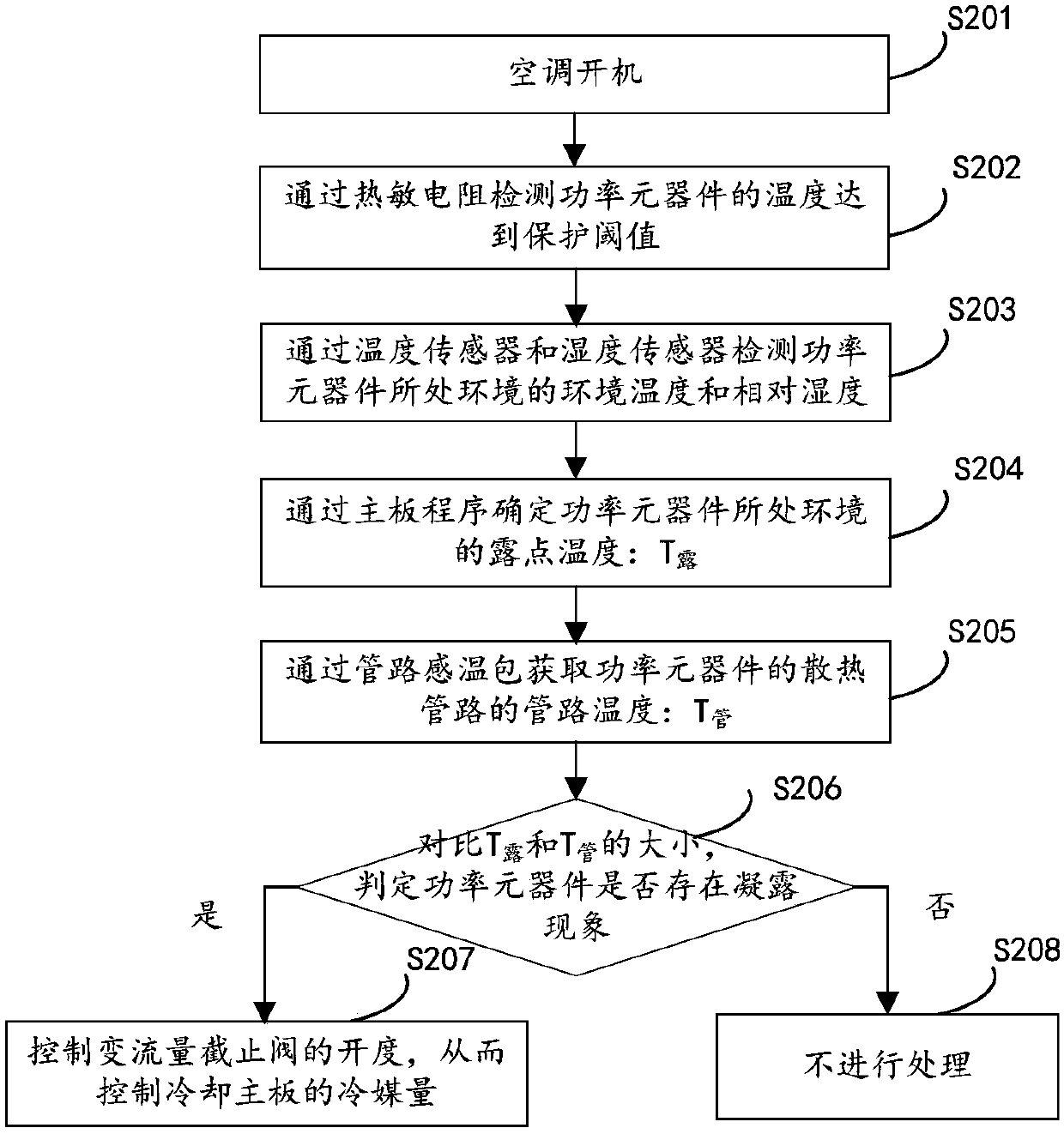

[0039] In this embodiment, the anti-condensation method is introduced by taking power components of an air conditioner as an example. Of course, it is not limited to an air conditioner, and can also be applied to other electrical equipment. figure 2 It is a flowchart of the anti-condensation method according to an embodiment of the present invention, such as figure 2 As shown, the method includes the following steps (step S201-step S208):

[0040] In step S201, the air conditioner is turned on.

[0041]Step S202, detecting that the temperature of the power component reaches a protection threshold through the thermistor, and the protection threshold can be set based on requirements.

[0042] Step S203, detecting the ambient temperature and relative humidity of the environment where the power components are located through the temperature sensor and the humidity sensor, wherein the ambient temperature is also called dry bulb temperature.

[0043] Step S204, determine the dew...

Embodiment 3

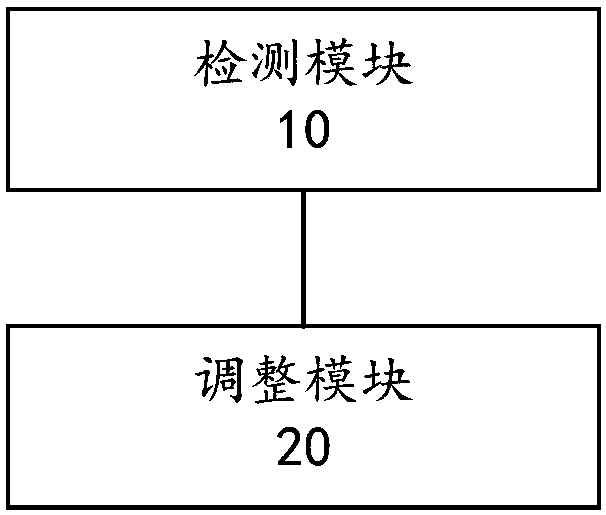

[0049] corresponds to figure 1 The power component anti-condensation method introduced, this embodiment provides a power component anti-condensation device, such as image 3 The structural block diagram of the anti-condensation device for power components shown, the device includes:

[0050] The detection module 10 is used to detect whether condensation occurs in the power components;

[0051] The adjustment module 20 is configured to adjust the cooling capacity of the refrigerant to eliminate the condensation when condensation is detected in the power components.

[0052] In this embodiment, by detecting whether there is condensation in the power components, the cooling amount of the refrigerant is controlled, and the heat dissipation of the power components can be realized simultaneously, so as to prevent excessive stress and strain of the power components, and problems such as premature aging of the main board caused by alternation of cold and heat; and It can realize no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com