Examination verification apparatus of high-frequency-current-method partial discharge detector and method thereof

A high-frequency current and partial discharge technology, which is applied to measuring devices, instruments, and measuring electrical variables, can solve problems such as the lack of a performance verification platform, hidden dangers in the safe operation of power equipment, and the impact on the effectiveness and reliability of power equipment. Easy to implement, simple and fast debugging, convenient and fast testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

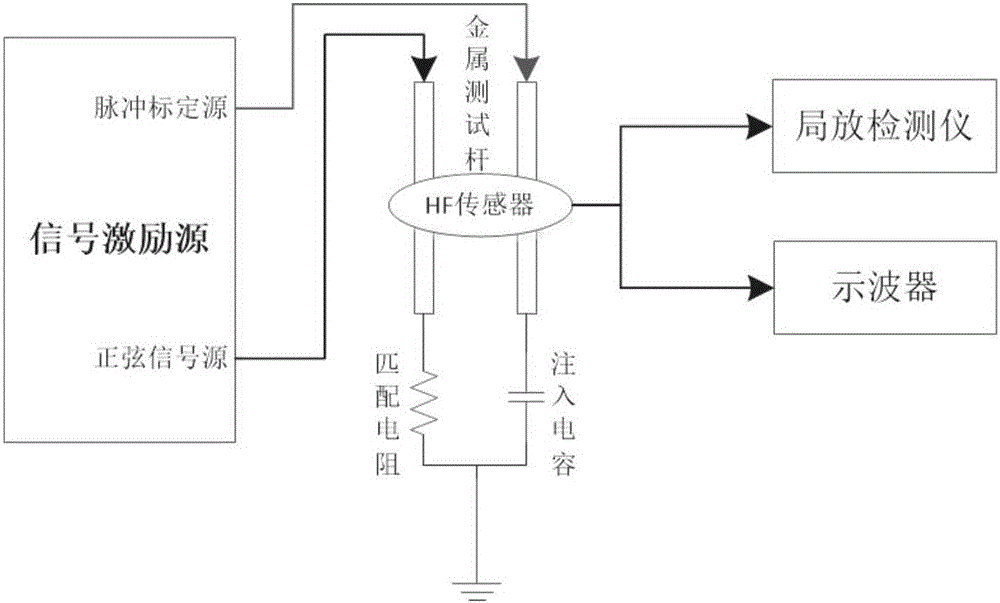

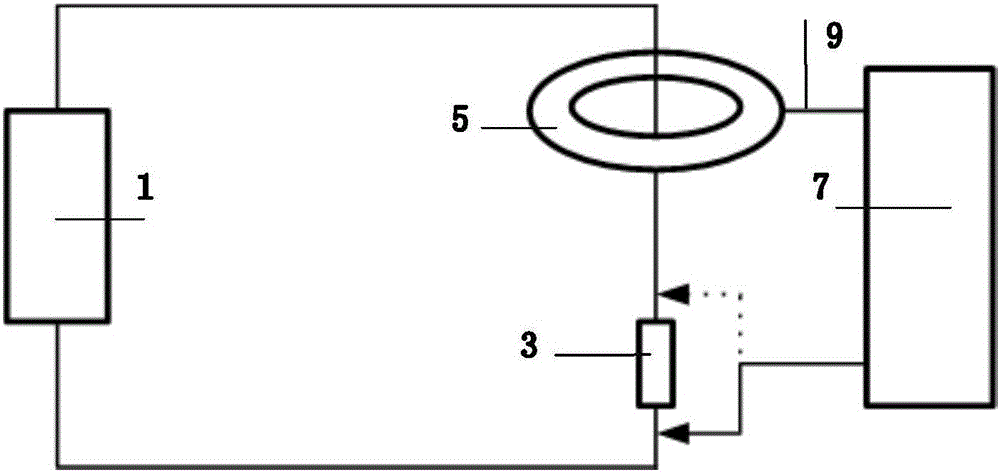

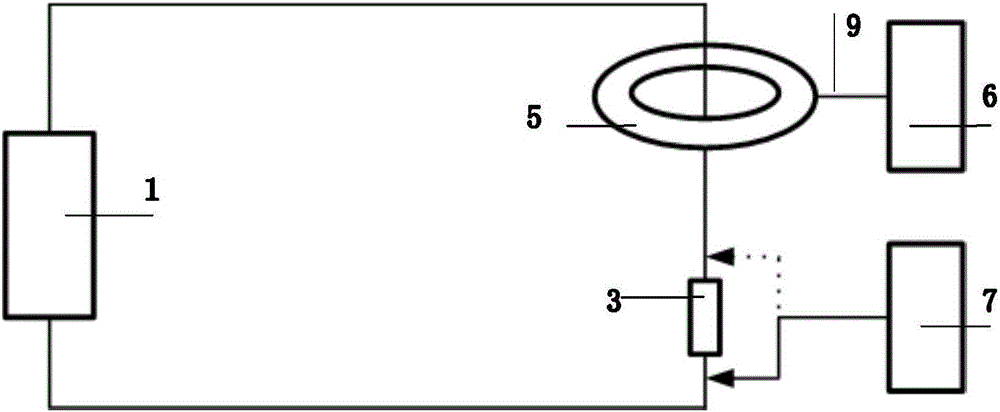

[0055] Such as figure 1 As shown, an assessment and verification device based on the high-frequency current method partial discharge detector, the device includes a signal excitation source, a matching resistor R 0 3. Injection capacitance C 0 4. The first metal test rod, the second metal test rod, an oscilloscope 7, and a 50Ω coaxial cable 9. The instrument under test includes a partial discharge detector 6 and a high-frequency sensor 5; the signal excitation source is a built-in signal source of the device, Divided into sine wave signal source 1 and pulse calibration source 2; the matching resistor R 0 The sine wave signal source and the first metal test rod are connected in series to form a sine signal loop; the injection capacitance C 0 The combination of the pulse calibration source and the second metal test rod in series forms a pulse signal loop; the two metal test rods are used to transmit high-frequency current signals; the high-frequency sensor (HFCT) is inserted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com