Precise motion path planning method for multi-axis mechanical system

A mechanical system and motion path technology, applied in the direction of manipulators, general control systems, control/regulation systems, etc., can solve the problems of inability to solve precise path planning, the inability of robots to complete the precise cutting path drawing of small circles, and the high price. The effect of portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

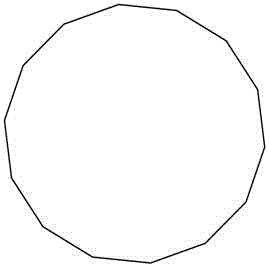

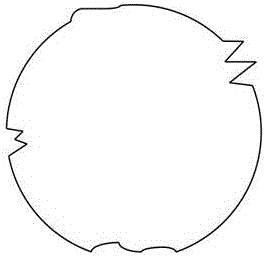

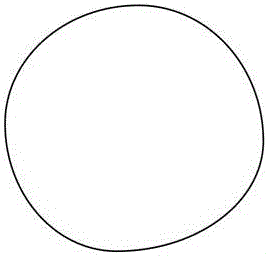

[0023] Embodiment: a multi-axis mechanical system precise motion path planning method, the specific method includes the following steps:

[0024] Step 1: Obtain information, obtain the type and model of the multi-axis mechanical system actually used, tool parameters, workpiece parameters, working environment conditions and process requirements. Analyze the reasons why the current path does not meet the process requirements, and consider how to solve it.

[0025] Among them, the types and models of multi-axis mechanical systems, such as ABB's 6-axis industrial robot IRB 120.

[0026] Tool type and model, such as IPG laser generator, lasemech laser three-dimensional cutting head.

[0027] The specific parameters of the workpiece, such as material, thickness, size, etc.

[0028] Working environment conditions, such as processing methods, installation environment, etc.

[0029] Process requirements, such as cutting circle size, cutting end surface roughness, etc.

[0030] Cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com