Method for designing tap positions of deicing transformer of direct current deicing device based on graphical method

A technology of transformer stalls and DC ice melting, applied in the field of electrical engineering, can solve problems such as lack of adaptability to line parameter changes, difficulty in achieving optimal design results, and too many transformer stalls, so as to achieve excellent design results and avoid repetition The effect of trial and error iterations and a small number of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

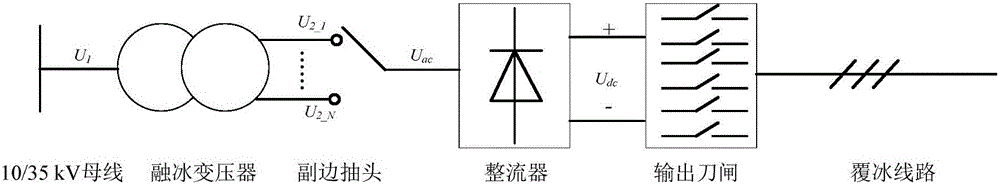

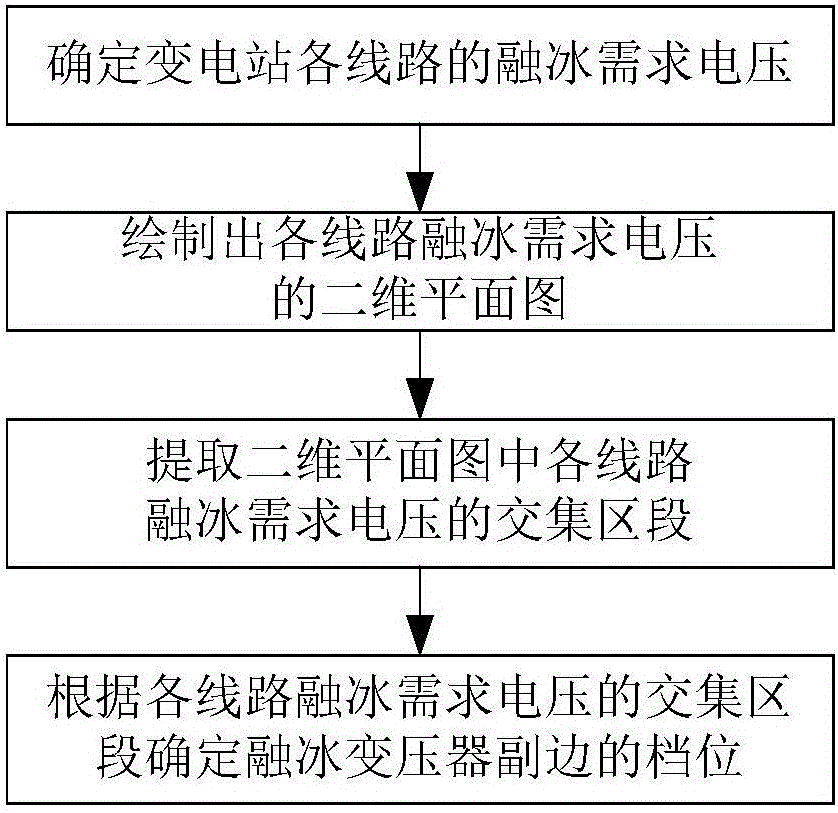

[0031] Such as figure 2 As shown, in this embodiment, the steps of the method for designing the stalls of the ice-melting transformer of the DC ice-melting device based on the graphical method include:

[0032] 1) Determine the ice-melting demand voltage of each line in the substation;

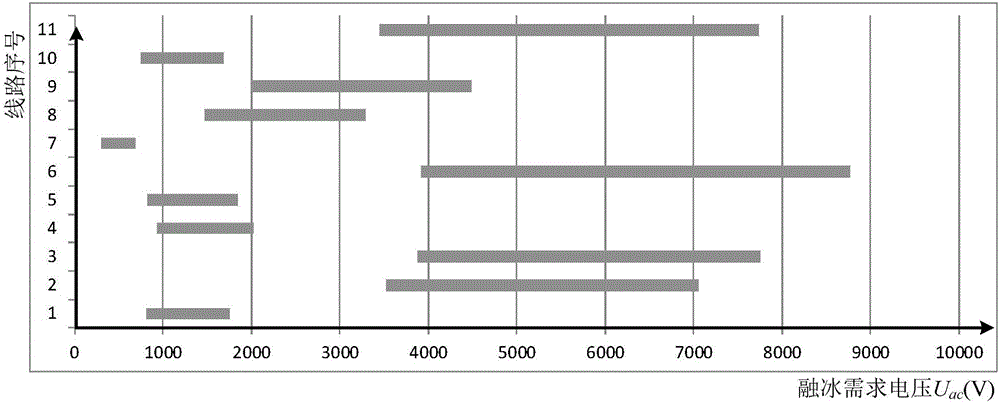

[0033] 2) Draw a two-dimensional plane diagram of the ice-melting demand voltage of each line;

[0034] 3) Extract the intersection section of the ice-melting demand voltage of each line in the two-dimensional plan;

[0035] 4) Determine the gear position of the secondary side of the ice-melting transformer according to the intersection section of the ice-melting demand voltage of each line.

[0036] In the present embodiment, the detailed steps of step 1) include:

[0037] 1.1) Determine the maximum allowable ice-melting current I of each line in the substation max and the minimum melting current I min ;

[0038] 1.2) According to the wiring mode of the transmission line during DC ice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com