Ice crusher motor

A technology of electromechanical and ice crushing, which is applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of inability to crush ice for a long time, high motor speed, and peculiar smell, etc., to extend the continuous ice crushing time and reduce the temperature. The effect of rising, strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

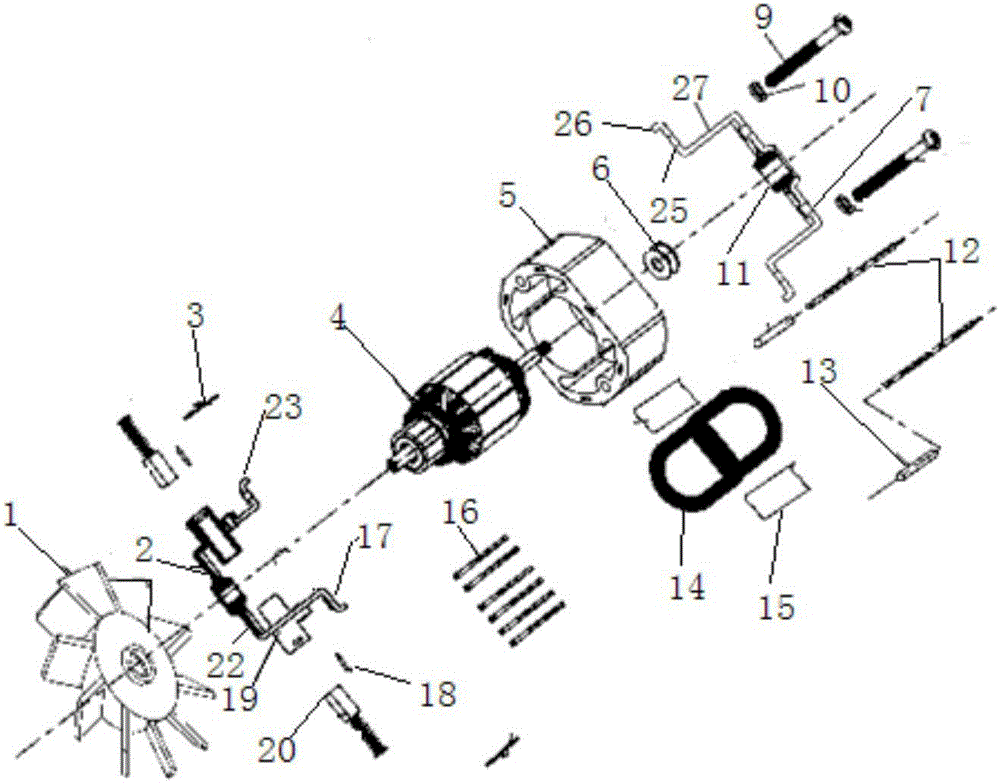

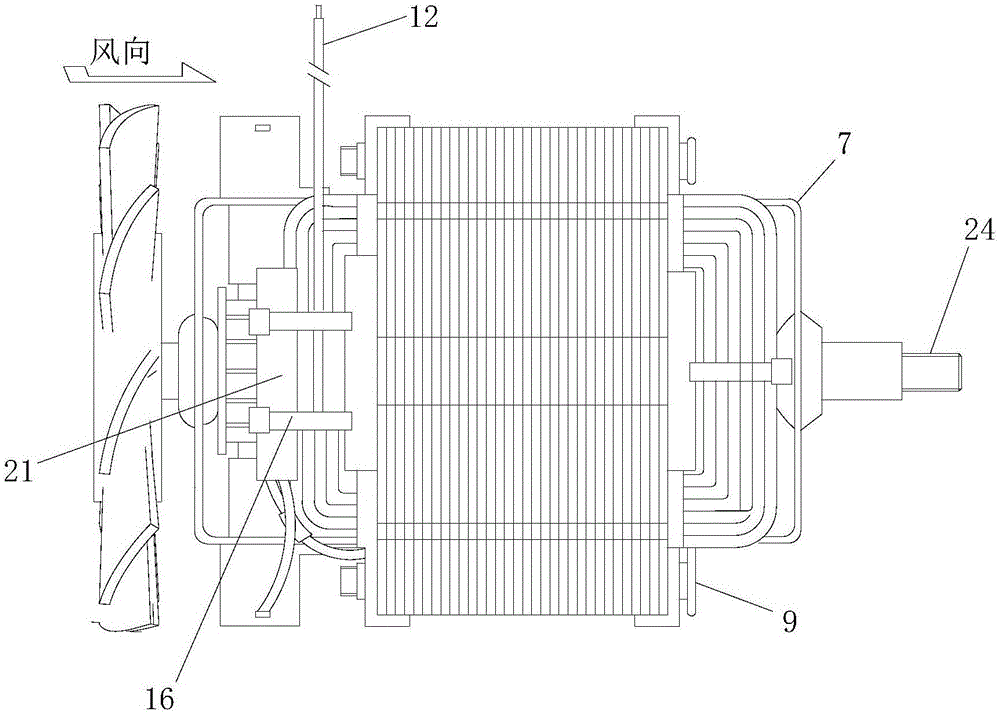

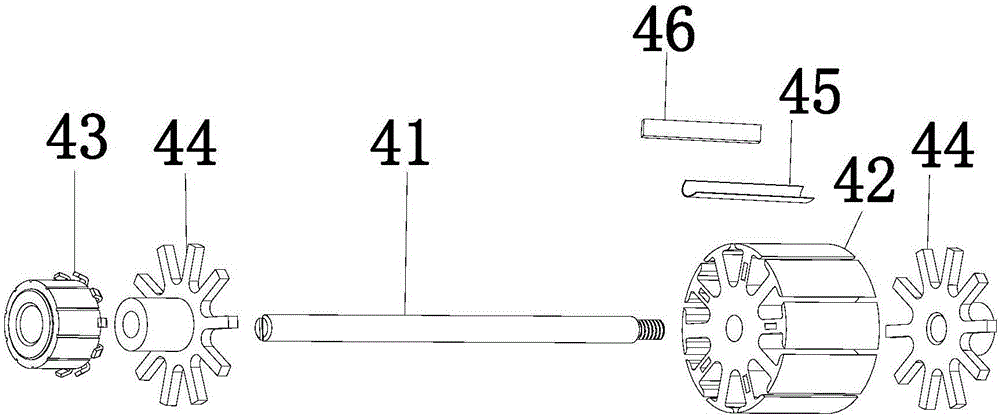

[0014] Example. Ice crusher motor, constituted as Figure 1-3 As shown, the stator core 5 is included, the stator core 5 is provided with a stator enameled wire 14 via masking tape 15, the stator core 5 is provided with a rotor 4, and the two ends of the rotor 4 are provided with a front end cover 7 and a bearing 11 respectively. The rear end cover 2 and the front end cover 7 include a front end cover body 27. The front end cover body 27 is provided with a front fixed edge 25 attached to the front end face of the stator iron core 5. The front cladding edge 26 on the outside of the core 5, the rear end cover 2 includes a rear end cover body 22, the rear end cover body 22 is provided with a rear fixed edge 17 attached to the rear end surface of the stator core 5, and the rear fixed edge 17 The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com