Automatic paint removing machine

A paint stripping and automatic technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of poor paint stripping quality, low efficiency, complicated coil winding, etc., to achieve compact equipment structure, simple and safe operation, The effect of high paint stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

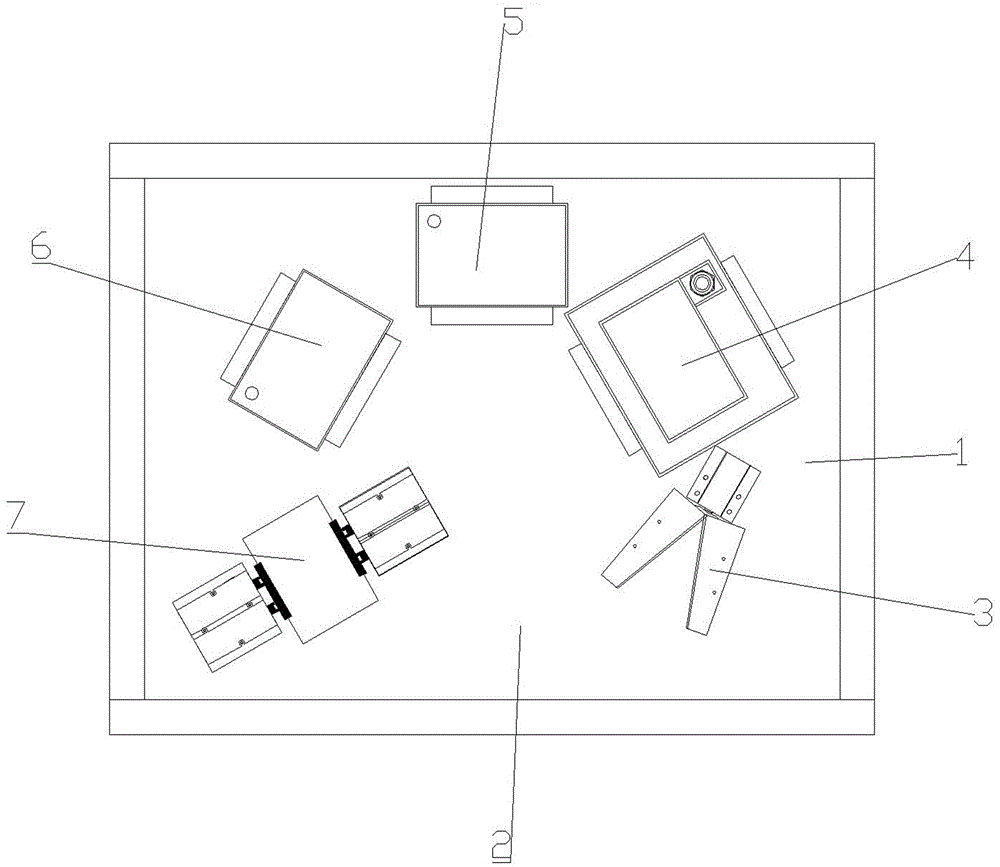

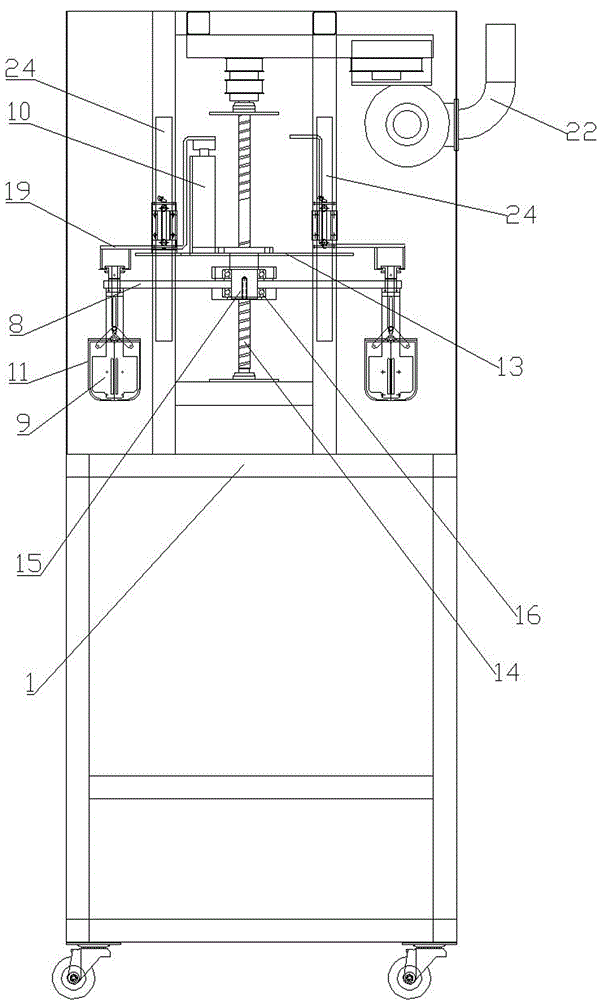

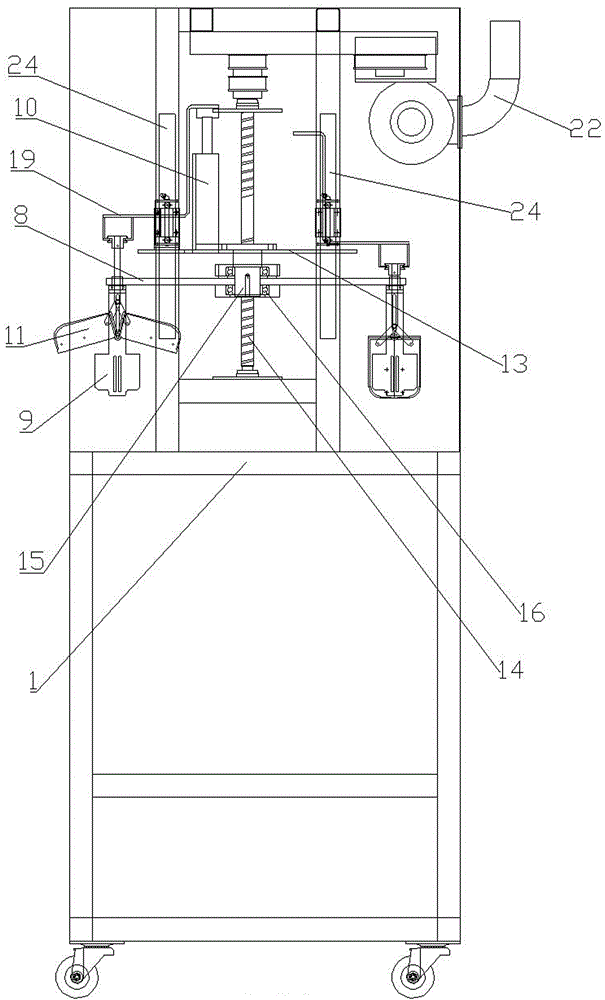

[0025] Such as figure 1 As shown, the automatic paint stripper that the present invention proposes comprises: machine platform 1 and the automatic paint stripping assembly that is located on the machine platform 1, is also provided with upper and lower parts district 2 on the machine platform 1, and the automatic paint stripping assembly includes: for The clipping mechanism 3 for cutting off the legs of the coil pins, the paint stripping mechanism 4 for soaking the coil pins to remove the paint, the cleaning mechanism 6 for cleaning the coil pins and the drying mechanism 7 for drying the coil pins. Preferably, the automatic paint removal assembly also includes a heating and cleaning mechanism 5 located between the paint removing mechanism 4 and the cleaning mechanism 6. After the pins of the coil are depainted, they are first cleaned by the heating and cleaning mechanism 5, and then passed through the cleaning mechanism 6 for the second time. Clean, clean better.

[0026] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com