Intelligent control-type cage lighting system and cage structure

A lighting system and intelligent control technology, applied in the field of poultry breeding, can solve the problems of limited light source lighting range, easy to be affected by cage layout, wind blowing, troublesome assembly and maintenance of LED light pipes, etc., to promote growth rate, The effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

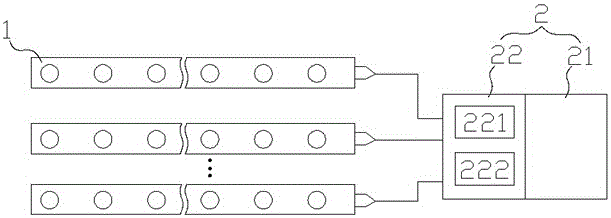

[0031] Applied to cages with one or more layers of structure, it includes several LED light strips 1 arranged on each floor of the cage, a controller 2 connected to the LED light strips 1 and a power supply, the controller 2 includes a control part 21 and The driving part 22, the control part 21 simulates the mean value change or the mean value proportional change in different periods of sunlight to adjust the required light color temperature and brightness. The light color temperature and brightness are both adjusted gradually. The color spectrum adjustment of the LED light strip 1 includes two modes of yellow light and white light. The LED strips 1 are driven by the driving part 22 , and the driving part 22 includes a color temperature adjustment circuit 221 and a light intensity adjustment circuit 222 .

[0032] The controller 2 is arranged on the side of the cage, and is connected to the LED light strip 1 through wires, and is provided with an operation panel or a communic...

Embodiment 2

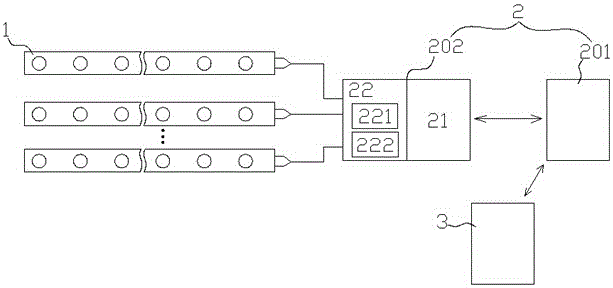

[0035] The difference from the first embodiment above is that the controller 2 includes a master controller 201 arranged in the monitoring center and a slave controller 202 arranged beside the cage, and the master controller 201 and the slave controller 202 are wirelessly connected. connection or via RS485 bus connection. The main controller 201 is provided with an operation panel or / and a communication module for wireless access and control of the smart terminal 3. The slave controller 202 includes a control part 21 and a drive part 22. The control part 21 simulates the average value of sunlight in different periods The required light color temperature and brightness are adjusted by the change or the average value is changed in proportion. The light color temperature and brightness are both gradually adjusted. The control part 21 also adjusts the color spectrum of the LED strip 1. Two modes of white light. These LED light strips 1 are driven by the drive part 22, the drive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com