A method for homogenizing the thickness of PCB board medium

A technology of dielectric thickness and PCB board, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve the problems that the impedance tolerance requirements cannot be met, and the manufacturing method is difficult to achieve, so as to achieve strong operability and applicability, and avoid dielectric The effect of thickness difference and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

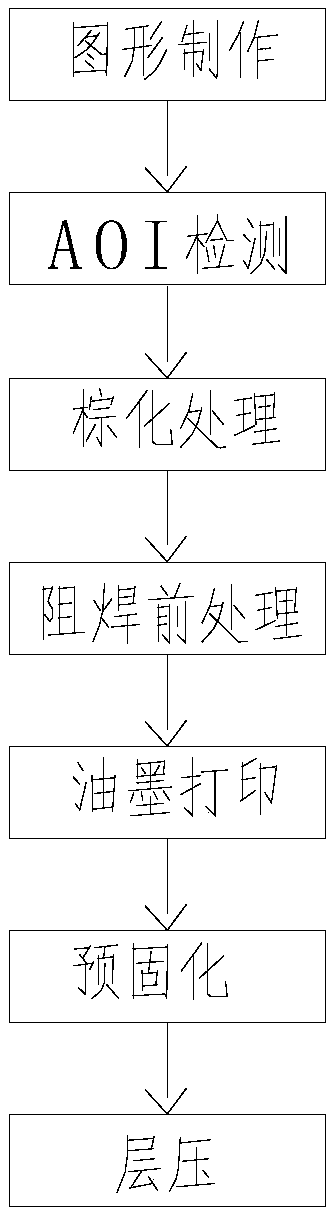

[0031] Such as figure 1 As shown, a method for homogenizing the medium thickness of a PCB comprises the following steps:

[0032] (1) Graphics production, making graphics on the inner copper core board;

[0033] (2) AOI inspection, AOI inspection is performed on the inner layer copper core board that has completed the graphic production;

[0034] (3) Browning treatment, browning treatment is carried out to the inner layer copper core board after AOI detection;

[0035] (4) pre-treatment of solder mask, carry out pre-treatment of solder mask to the inner layer copper core board that has completed the browning treatment;

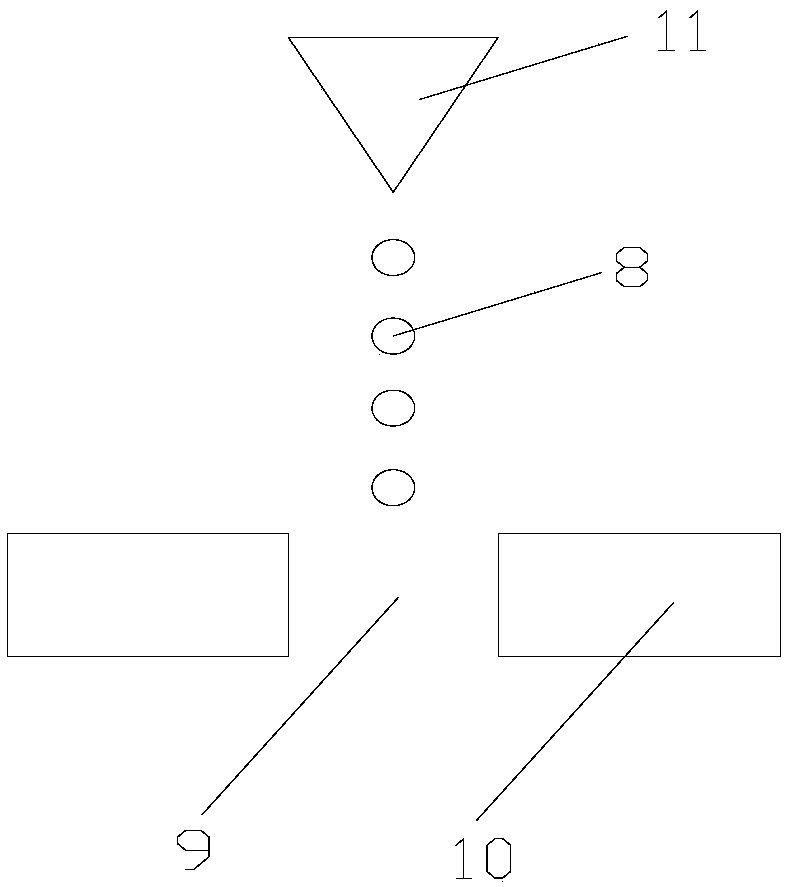

[0036] (5) ink printing, such as figure 2 As shown, using 3D printing technology to print ink on the inner copper core board that has completed the pre-soldering process, so that the ink 8 completely fills the line gap 9 on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com