Fragrance recycling method based on multistage condensers

A technology of aroma recovery and condenser, which is applied in the direction of chemical instruments and methods, separation methods, multi-effect/separation condensation, etc. It can solve the problems of high energy consumption, long cooling time, and unsatisfactory recovery of aroma components, etc., and achieves energy reduction. Consumption, increased disturbance, and improved recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

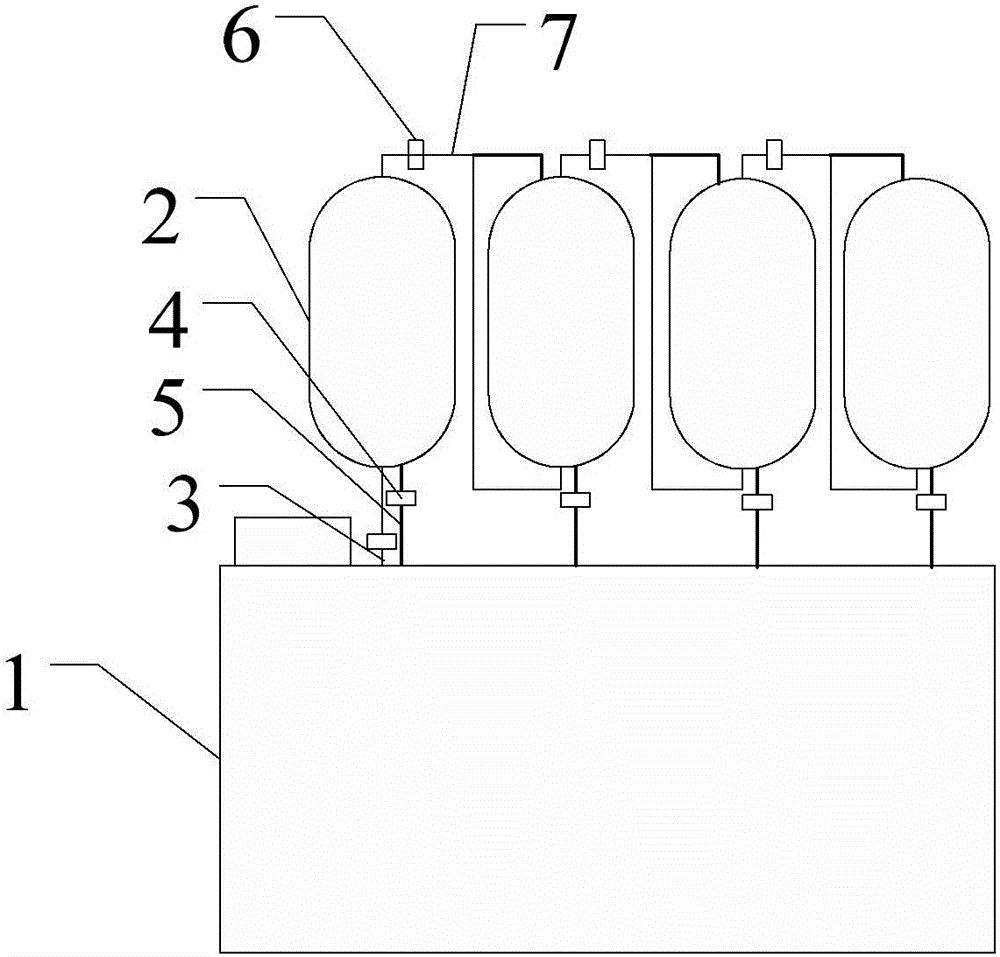

[0017] Such as figure 1 As shown, the present invention provides a method for recovering aroma based on a multi-stage condenser, comprising: providing a reaction tank 1 in which a Maillard reaction is carried out; providing a multi-stage condenser 2, a multi-stage condenser 2 It is arranged above the reaction tank 1, and the multi-stage condenser is distributed along the horizontal direction, and the bottom end of the first-stage condenser is connected to the reaction tank 1 through the air inlet line 3 from front to back, and the front-stage condenser The top of the condenser is simultaneously connected to the bottom and top of the subsequent condenser through the first pipeline 7, a drain pipe 5 is arranged at the bottom of each condenser, and a first valve is arranged on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com