Three-layer composite double-face knitted fabric and its production process

A knitted fabric and composite double-sided technology, which is applied in the field of clothing fabrics, can solve problems such as complex production process and process, complex production process, and difficult quality control, and achieve the effects of strong practicability, simple composite process, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

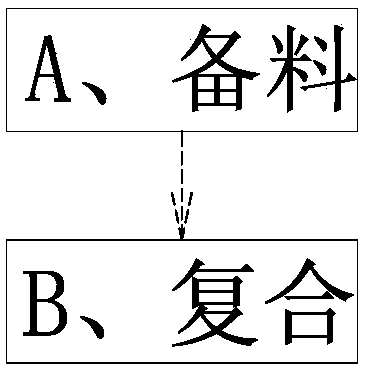

Method used

Image

Examples

Embodiment 1

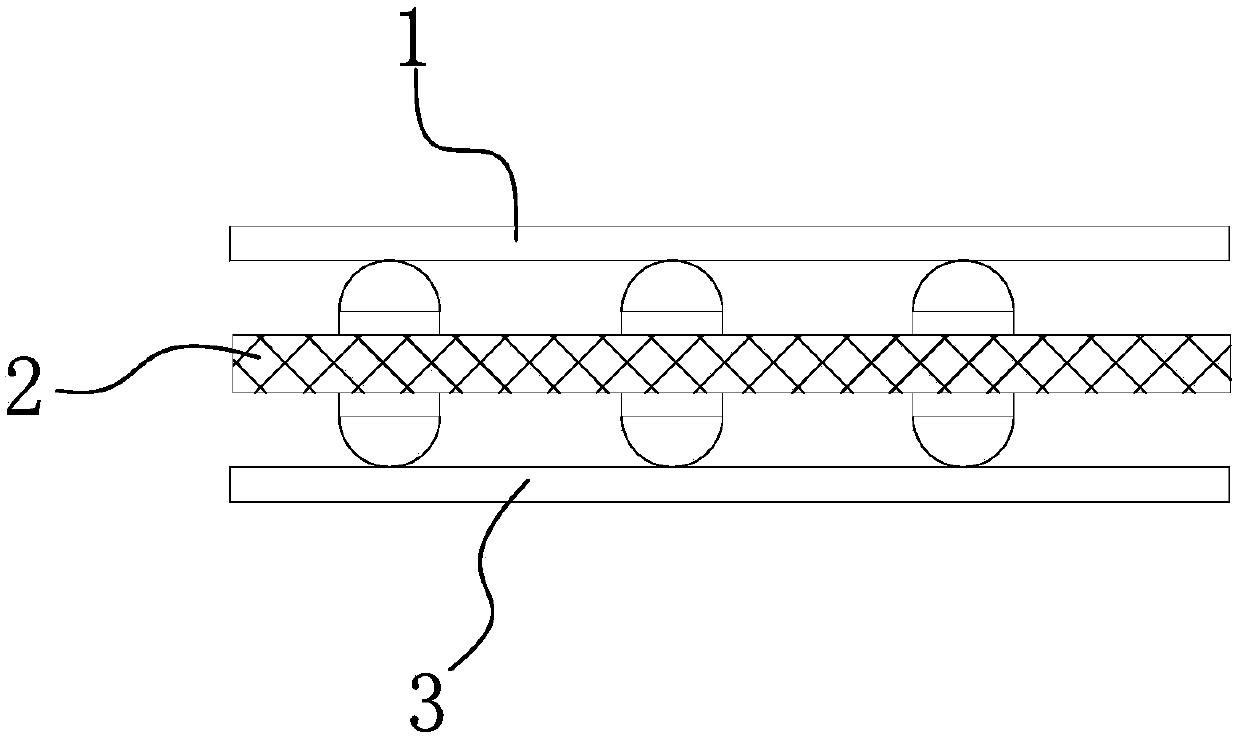

[0089] Three-layer composite knitted double-sided fabric

[0090] In the above step A, select knitted wool fabric as the first fabric 1 and the second fabric 3, and the square weight of the fabric is 266 g / m2. The fabric includes the following components: wool 50-60% and polyester 40%; Choose double-sided rubberized nylon high-elastic woven 1 / 3 twill base fabric as the middle layer 2 and its square weight is 65-66 g / m2;

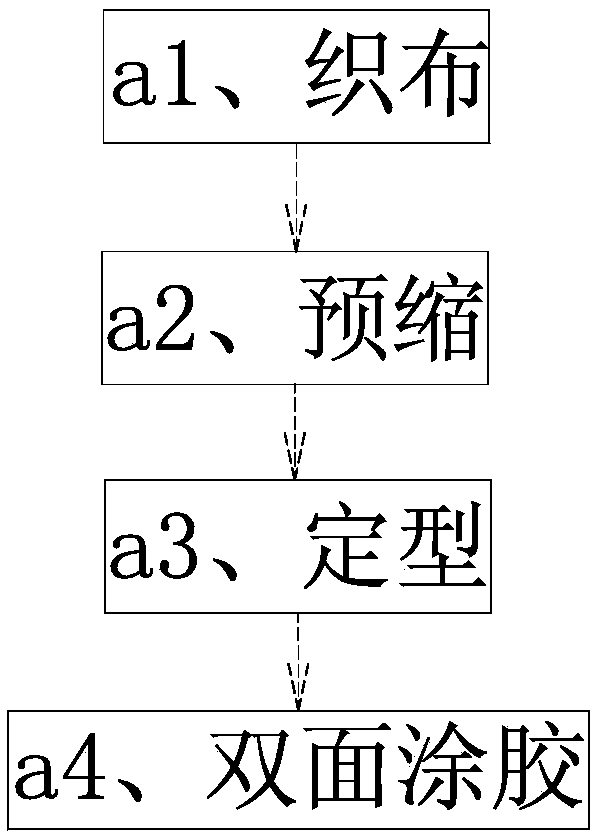

[0091] The processing process of double-sided rubberized nylon high elastic woven 1 / 3 twill base fabric is as follows:

[0092] In the above step a1, select PA66 DTY micro-mesh 15D / 5F warp yarns and PA6 DTY 150D / 48F weft yarns, and then slightly sizing the warp yarns. Because the warp yarns are very thin, in order to weave the fabric smoothly, Warp yarns are slightly sizing treated, and water jet loom or air jet loom is used to twill weave the warp and weft yarns and make a high elastic woven twill grey fabric with a warp and weft density of 29×12 threads / cm. When...

Embodiment 2

[0102] The structure and principle of this embodiment are basically the same as those of the first embodiment, so it will not be repeated here. The differences are:

[0103] Three-layer composite textile fabric

[0104] In the above step A, select knitted woolen cloth as the first fabric 1 and the square weight of the fabric is 266 g / m2. The fabric includes the following ingredients: wool 50-60%, polyester 40-50%; select double-sided The rubberized nylon high-elastic woven 2 / 2 twill base fabric is the middle layer 2 and its square weight is 72-73 g / m2; choose the modal knitted jersey with spandex as the second fabric 3 and the square of the fabric The gram weight is 240 grams / square meter, and the second fabric 3 includes the following components: spandex 5% and modal fiber 95%.

[0105] The processing process of double-sided rubberized nylon high elastic woven 2 / 2 twill base fabric is as follows:

[0106] In the above step a1, select the warp yarns of PA66 DTY micro mesh 15D / 5F, sel...

Embodiment 3

[0116] The structure and principle of this embodiment are basically the same as those of the first embodiment, so it will not be repeated here. The differences are:

[0117] In the above step A, select the knitted wool fabric as the first fabric 1 and the square weight of the fabric is 130 g / m2. The fabric includes the following ingredients: wool 75%, polyester PTT 20%, spandex 5%; select double-sided The rubberized nylon high-elastic woven 2 / 2 twill base fabric is the middle layer 2 and its square weight is 62-64 g / m²; choose the spandex-containing rayon knitted jersey as the second fabric 3 and its fabric The square gram weight is 200 grams / square meter, and the second fabric 3 includes the following components: spandex 5% and rayon 95%.

[0118] The processing process of double-sided rubberized nylon high elastic woven 2 / 2 twill base fabric is as follows:

[0119] In the above step a1, select the warp yarns of PA66 DTY micro mesh 15D / 5F, select the weft yarns of PA6 DTY 140D / 48F,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com