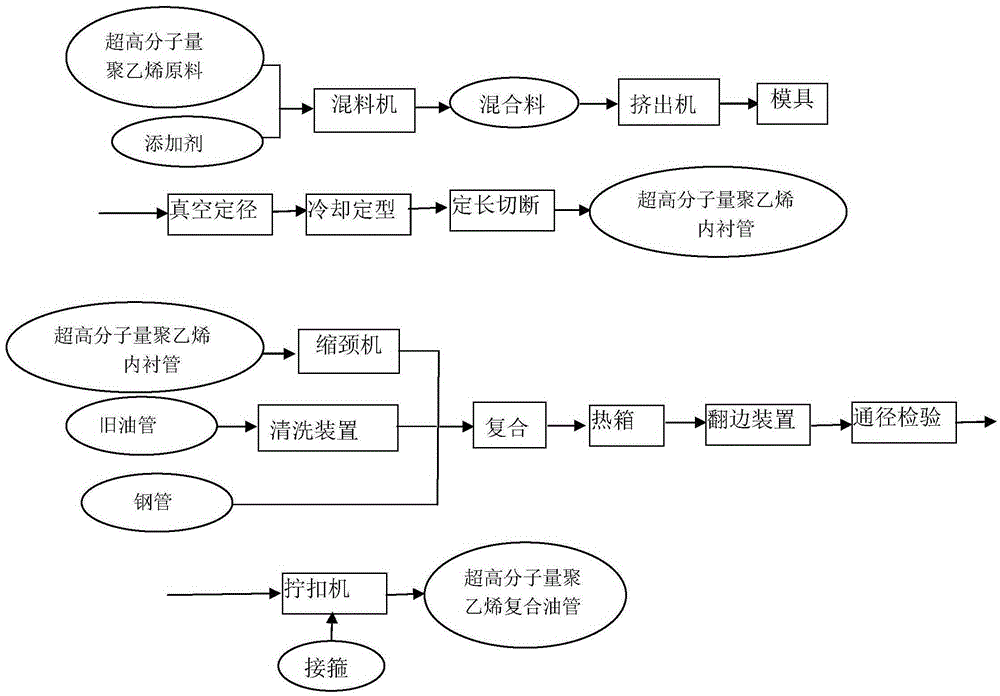

Production method of ultra-high molecular weight polyethylene composite oil pipe

A technology of ultra-high molecular weight, composite tubing, applied in the field of ultra-high molecular weight polyethylene composite tubing production technology and production system, can solve the problems of poor adhesion between ultra-high molecular weight polyethylene materials and steel pipes, finished product quality and quality stability Poor consistency, complex processing procedures, etc., to achieve the effects of reduced control and operation difficulty, good memory, and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

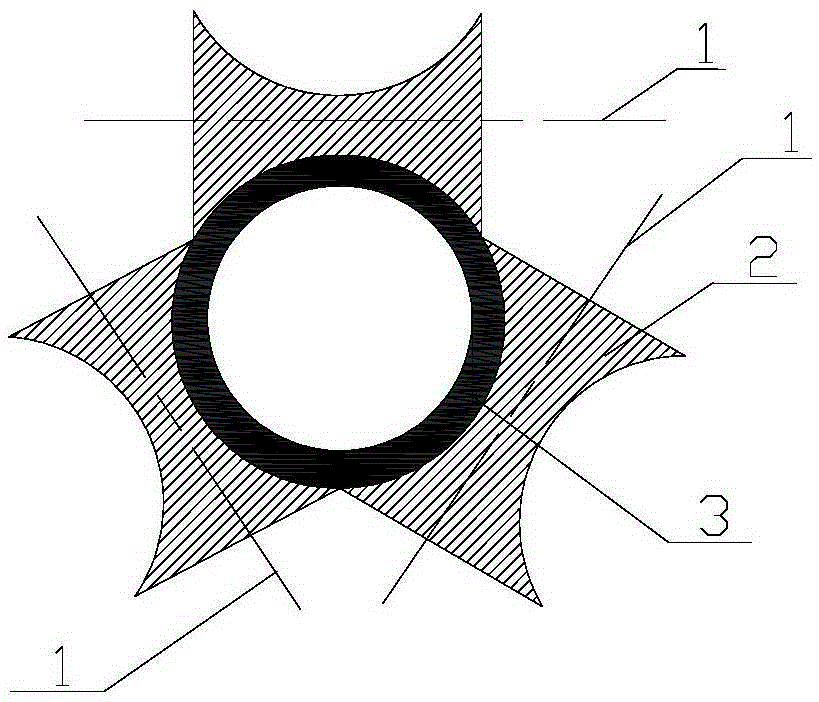

[0059] The inner diameter of the ultra-high molecular weight polyethylene lined pipe is 53±0.5mm, the outer diameter is 65±0.2mm, and the wall thickness is 3.4~3.7mm;

[0060] The outer diameter of the steel pipe is 75±0.2mm, the diameter of the pipe gauge is 51mm, the length of the gauge is 1200mm, and the minimum length of the coupling is 158mm.

[0061] In this embodiment, after the ultra-high molecular weight polyethylene lined pipe is combined with the steel pipe, before the parts protruding from the steel pipe at both ends of the lined pipe are flanged through the flanging device, the liner pipe needs to be pulled out from the steel pipe. The pull-out force is greater than 10KN.

Embodiment 2

[0063] The inner diameter of ultra-high molecular weight polyethylene lined pipe is 67±0.5mm, the outer diameter is 79±0.2mm, and the wall thickness is 4.2~4.5mm;

[0064] The outer diameter of the steel pipe is 89±0.2mm, the diameter of the drift gauge is 51mm, the length of the drift gauge is 1200mm, and the minimum length of the coupling is 171mm.

[0065] In this embodiment, after the ultra-high molecular weight polyethylene lined pipe is combined with the steel pipe, before the parts protruding from the steel pipe at both ends of the lined pipe are flanged through the flanging device, the liner pipe needs to be pulled out from the steel pipe. The pull-out force is greater than 12KN.

Embodiment 3

[0067] The inner diameter of ultra-high molecular weight polyethylene lined pipe is 90±0.5mm, the outer diameter is 105±0.2mm, and the wall thickness is 4.7~5.3mm;

[0068] The outer diameter of the steel pipe is 119±0.2mm, the diameter of the drift gauge is 86mm, the length of the drift gauge is 1200mm, and the minimum length of the coupling is 186mm.

[0069] In this embodiment, after the ultra-high molecular weight polyethylene lined pipe is combined with the steel pipe, before the parts protruding from the steel pipe at both ends of the lined pipe are flanged through the flanging device, the liner pipe needs to be pulled out from the steel pipe. The pull-out force is greater than 14KN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com