A kind of electromagnetic shielding foam composite material and preparation method based on graphene oxide and polymer

A composite material and graphene technology, which is applied in the field of preparation of graphene oxide and flexible polymer foam composite materials, can solve the problems of insufficient flexibility and low electromagnetic shielding performance, and achieve excellent mechanical and electromagnetic shielding performance and low content requirements , the effect of simple compound process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

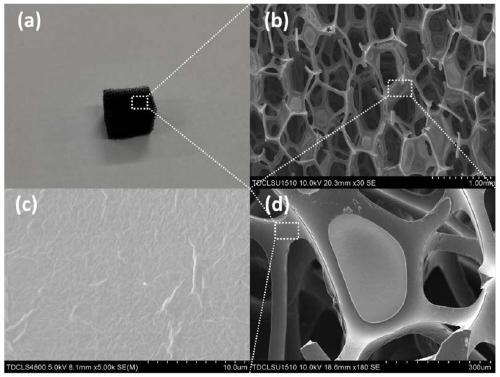

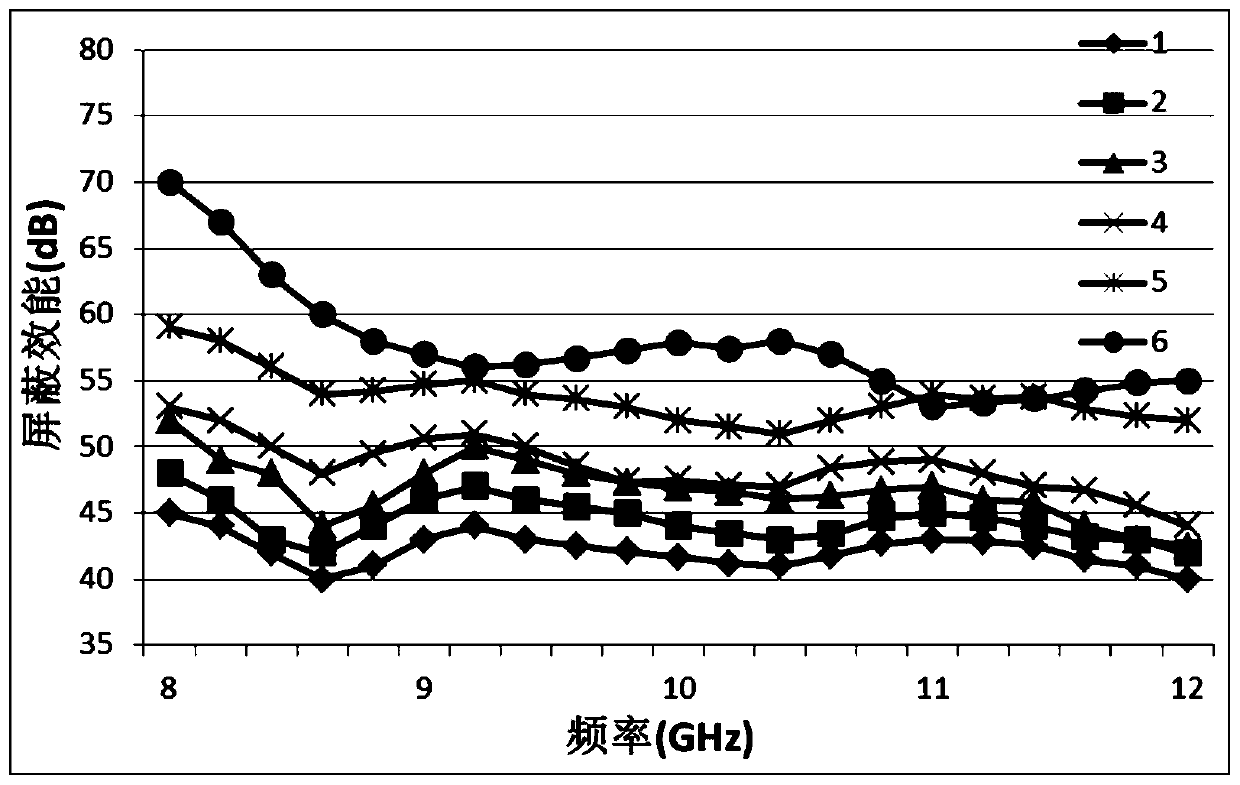

Embodiment 1

[0026] Freeze-dry the neutral graphene oxide aqueous dispersion to obtain graphene oxide powder, add 100 mg of graphene oxide powder to 20 g of deionized water, and place them in a cell pulverizer for 20 minutes at a power of 20 W to obtain a mass Graphene oxide aqueous dispersion with a fraction of 0.05%; cut the open-cell polyurethane foam into 9.9g cubes, soak it in the above-mentioned graphene oxide aqueous dispersion, repeatedly extrude the polyurethane foam to make the graphene oxide aqueous dispersion uniform Adsorbed in the pores of the polyurethane foam, the mass ratio of the polyurethane foam to graphene oxide is 99:1, and after vacuum drying, the foam composite material based on graphene oxide is obtained; the above-mentioned foam composite material based on graphene oxide is placed In a hydrazine hydrate solution with a mass fraction of 0.5%, reflux at 60° C. for 3 h, wash with water, and dry to obtain a foam composite material based on reduced graphene oxide. The ...

Embodiment 2

[0028]Freeze-dry the neutral graphene oxide aqueous dispersion to obtain graphene oxide powder, add 100 mg of graphene oxide powder to 20 g of deionized water, and place them in a cell pulverizer for 3 minutes at a power of 200 W to obtain a mass Graphene oxide aqueous dispersion with a fraction of 0.05%; cut the open-cell polyurethane foam into 9.9g cubes, soak it in the above-mentioned graphene oxide aqueous dispersion, repeatedly extrude the polyurethane foam to make the graphene oxide aqueous dispersion uniform Adsorbed in the pores of the polyurethane foam, the mass ratio of the polyurethane foam to graphene oxide is 99:1, and after vacuum drying, the foam composite material based on graphene oxide is obtained; the above-mentioned foam composite material based on graphene oxide is placed In a hydrazine hydrate solution with a mass fraction of 1%, reflux at 80° C. for 3 h, wash with water, and dry to obtain a foam composite material based on reduced graphene oxide. The obt...

Embodiment 3

[0030] Freeze-dry the neutral graphene oxide aqueous dispersion to obtain graphene oxide powder, add 100 mg of graphene oxide powder to 20 g of deionized water, and place them in a cell pulverizer for 10 minutes at a power of 100 W to obtain a mass Graphene oxide aqueous dispersion with a fraction of 0.05%; cut the open-cell polyurethane foam into 9.9g cubes, soak it in the above-mentioned graphene oxide aqueous dispersion, repeatedly extrude the polyurethane foam to make the graphene oxide aqueous dispersion uniform Adsorbed in the pores of the polyurethane foam, the mass ratio of the polyurethane foam to graphene oxide is 99:1, and after vacuum drying, the foam composite material based on graphene oxide is obtained; the above-mentioned foam composite material based on graphene oxide is placed In a hydrazine hydrate solution with a mass fraction of 40%, reflux at 120° C. for 0.5 h, wash with water, and dry to obtain a foam composite material based on reduced graphene oxide. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com