Lithium ion capacitor negative electrode pre-lithiation method, composite negative electrode and lithium ion capacitor

A lithium ion and capacitor technology, applied in the field of energy storage, can solve the problems of excessive lithium supplementation, unfavorable long-term cycling of capacitors, and long pre-lithiation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

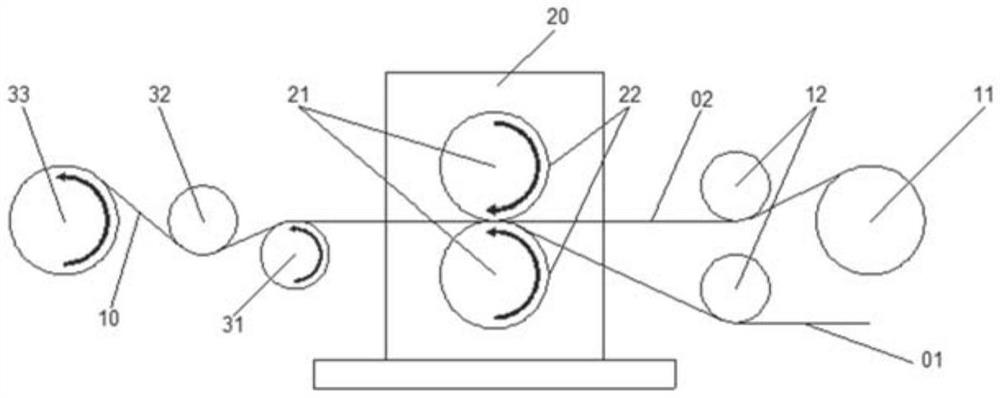

[0079] figure 1 A schematic diagram of a process for preparing a through-hole lithium film according to the present invention is shown. Such as figure 1 As shown, using the carrier strip 01 and the metal lithium strip 02 as raw materials, the unwinding equipment is used for unwinding, and the unwinding equipment includes at least a metal lithium strip unwinding roller 11 and a metal lithium strip for supporting unwinding. Two unwinding support rolls 12 of the lithium strip and the load strip; the raw material lithium strip 02 and the load strip 01 enter the rolling mill 20 after passing through the unwinding support roll 12; the rolling mill 20 includes at least a pair of rolls 21 and the Anti-sticking coating 22, the rolling pressure of described rolling mill 20 and the roll gap gap between rolls 21 can be fine-tuned; One or more of them, such as materials, ceramics, etc.; through pressure compounding, the carrying strip and lithium material are compounded together to form ...

Embodiment 1

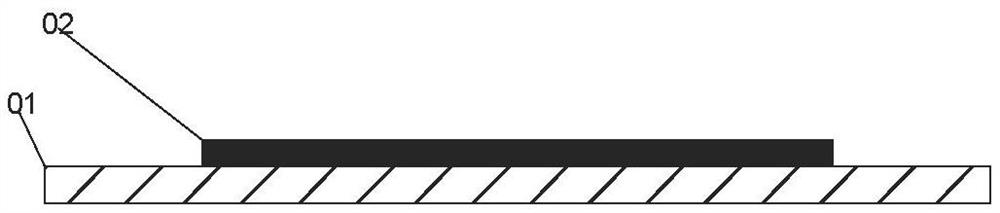

[0085] A 50-micron thick polyethylene film is used as the supporting layer, and the unwinding and winding device is assisted, and the lithium film thickness is 5 microns (the thickness tolerance is ±0.5 microns) covered with the supporting layer. Porous lithium film, the rolling process such as figure 1 As shown, the obtained lithium film structure covered with the loading layer is as follows figure 2 shown. Among them, the through-hole lithium film has a relatively complete film shape, and the film has relatively uniformly distributed pinhole-shaped (through the film) through holes, the size of the holes is 5-50 microns, and the hole spacing is 5-100 microns.

Embodiment 2

[0087] 1. List of materials

[0088]

[0089] 2. Preparation of positive and negative electrodes

[0090] 2.1. Preparation of positive electrode sheet

[0091] Weigh each substance according to the ratio of activated carbon:PVDF:AB=8:1:1, and add a certain mass of NMP, so that the solid content of the slurry is 30%. At room temperature, stir magnetically for 8 hours at about 800 r / min. Coat the stirred slurry on aluminum foil, dry it at 80 degrees Celsius for 12 hours, and then punch it into a circular positive electrode sheet with a diameter of 15mm. The surface density of activated carbon in the electrode sheet is about 7.8mg / cm 2 .

[0092] 2.2. Preparation of negative electrode sheet and composite negative electrode sheet

[0093]The preparation process of the negative pole piece is the same as the preparation process of the positive pole piece. The specific process is: according to the ratio of mesocarbon microspheres: PVDF: AB = 8:1:1, each material is weighed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com