Connection structure for aluminum vehicle body end of rail vehicle

An aluminum alloy car body and end connection technology, applied in railway car body parts, railway car body, railway roof and other directions, can solve the problems of reducing the strength and rigidity of the whole car, leakage of rivets and angle aluminum, and water leakage of the car body. , to achieve the effect of improving the quality and strength of the welding surface, improving the strength and stiffness, and ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

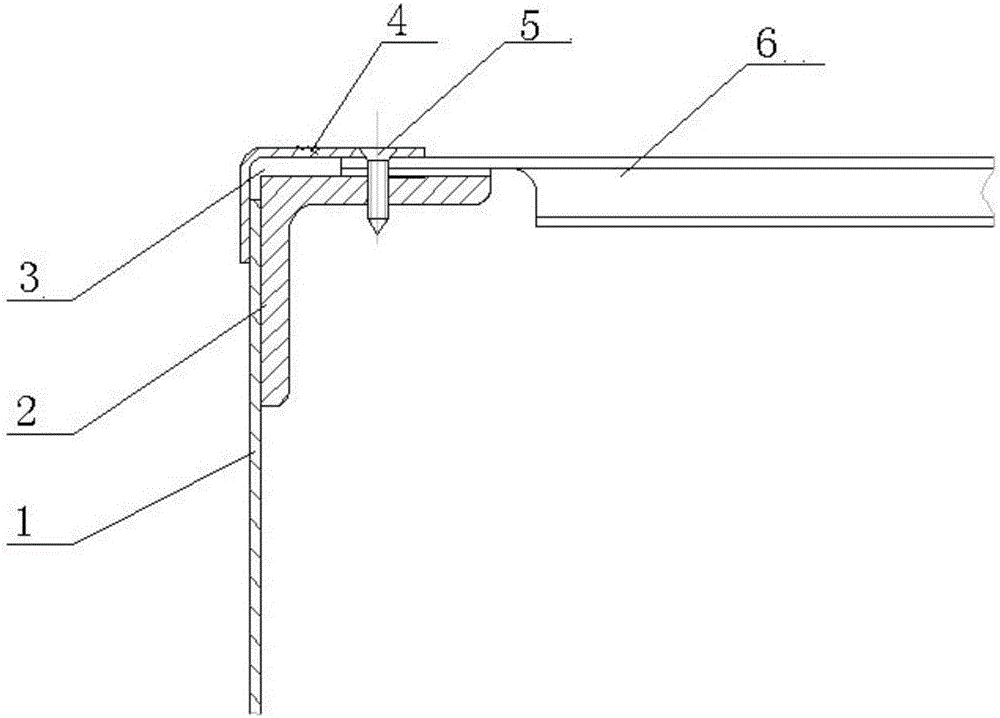

[0014] refer to figure 1 , the connection of the roof 6 and the end wall 1 of the original car body is to adopt the inner and outer two-layer angle aluminum 2, 4 connection structure, the inner welding, the outer riveting connection, the sealant 3 is applied to the gap between the inner and outer angle aluminum, and the connection of the side wall is the same reason. This connection method has the problem that after the car body has been used for a period of time, the rivet 5 will loosen or the sealant will age, which will easily cause water leakage from the car body, and both the rivet and the angle aluminum will leak outside, which will affect the appearance of the whole body. Reduce the strength and rigidity of the vehicle.

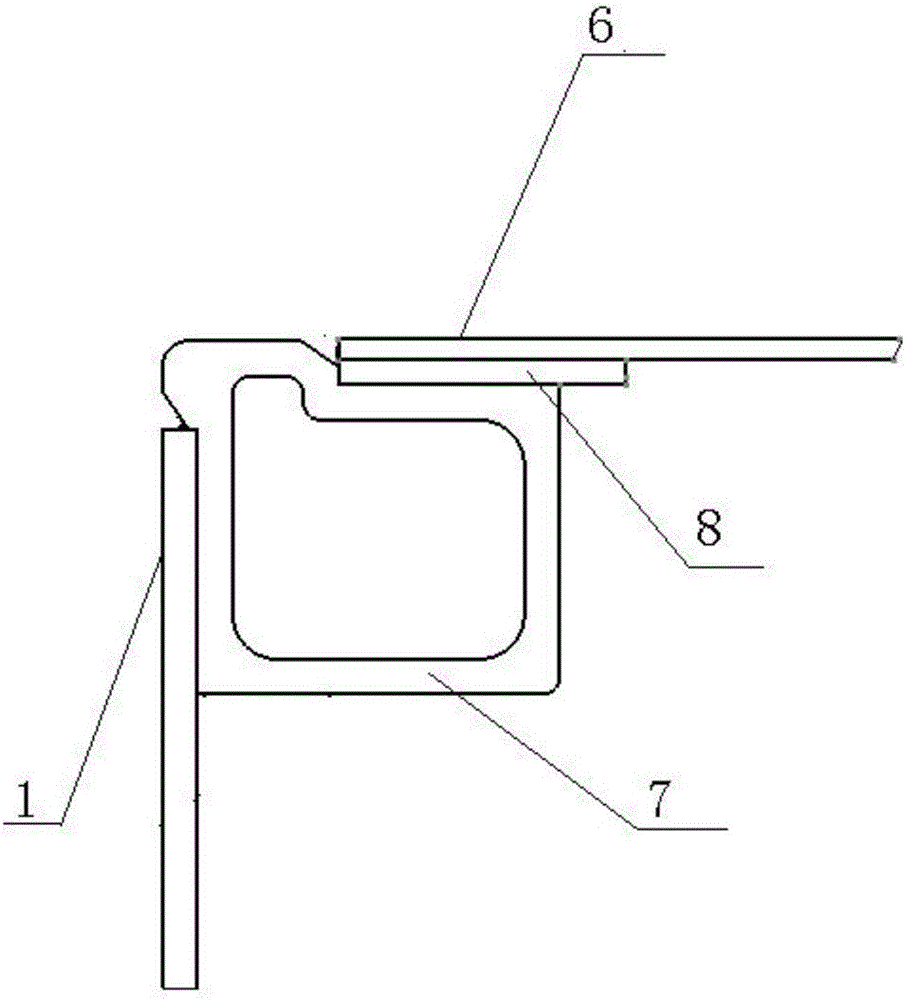

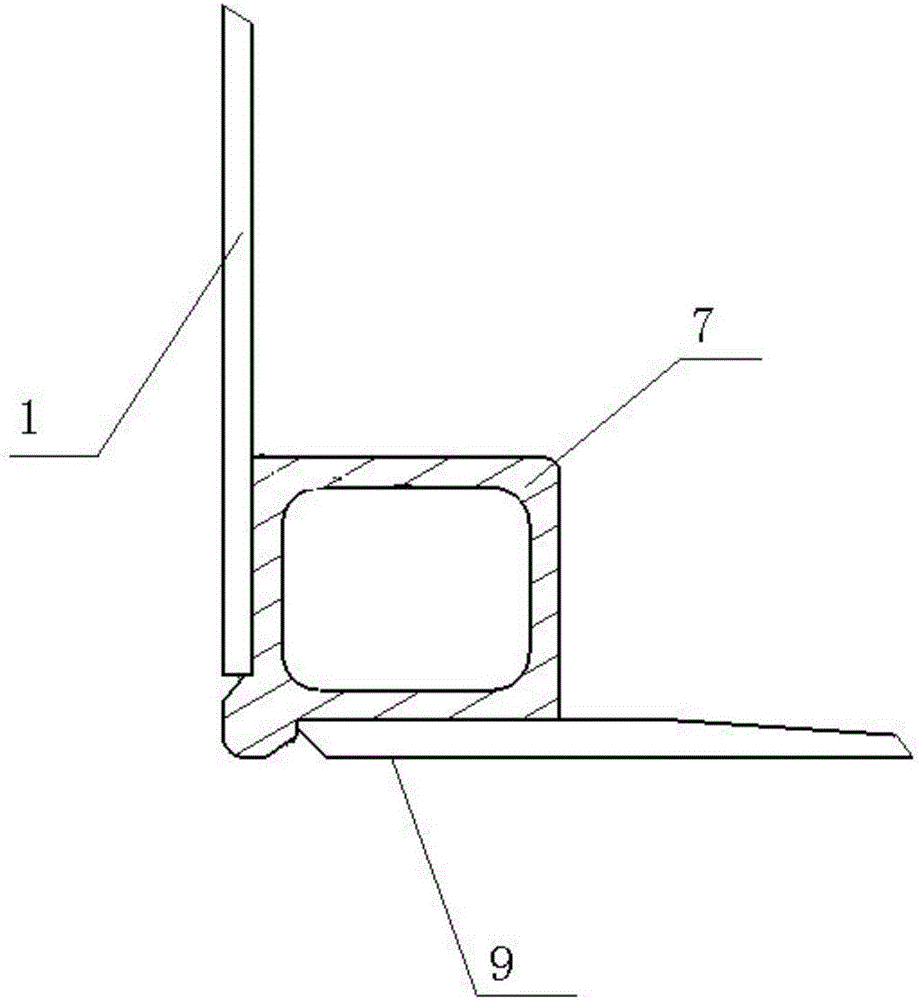

[0015] refer to figure 2 , image 3 , The specific embodiment of the present invention welds the square tubular closed profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com