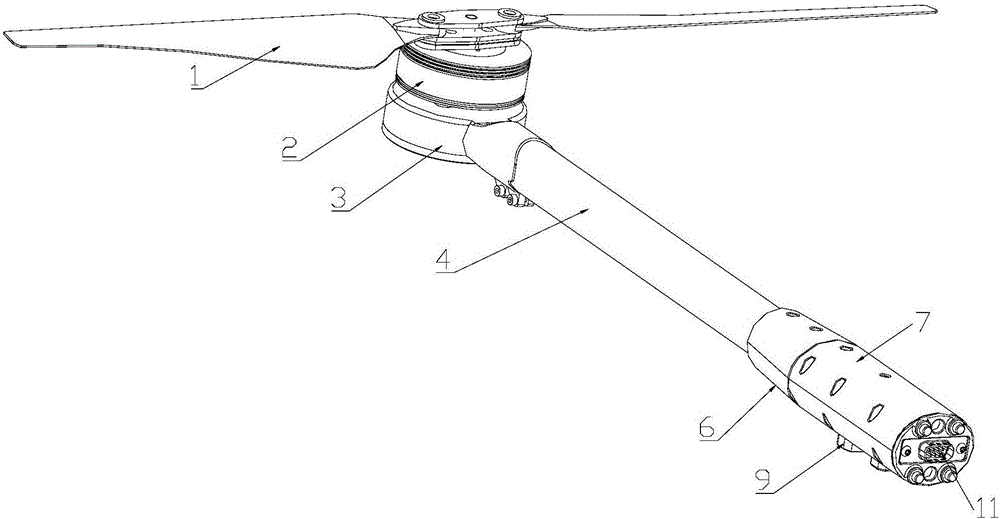

Six-rotor quick-release unmanned aerial vehicle arm

A technology of six rotors and arms, which is applied in the field of quick dismantling arms of six-rotor UAVs, can solve the problems of low integration of the arms, side deviation of the overall center of gravity, and reduced work efficiency, so as to shorten the production and processing time, reduce the Overall weight, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

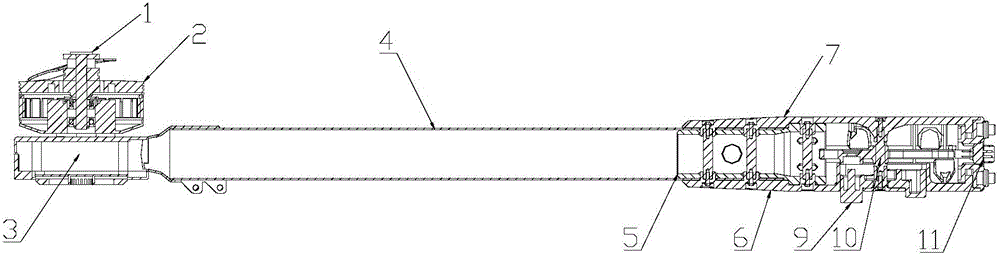

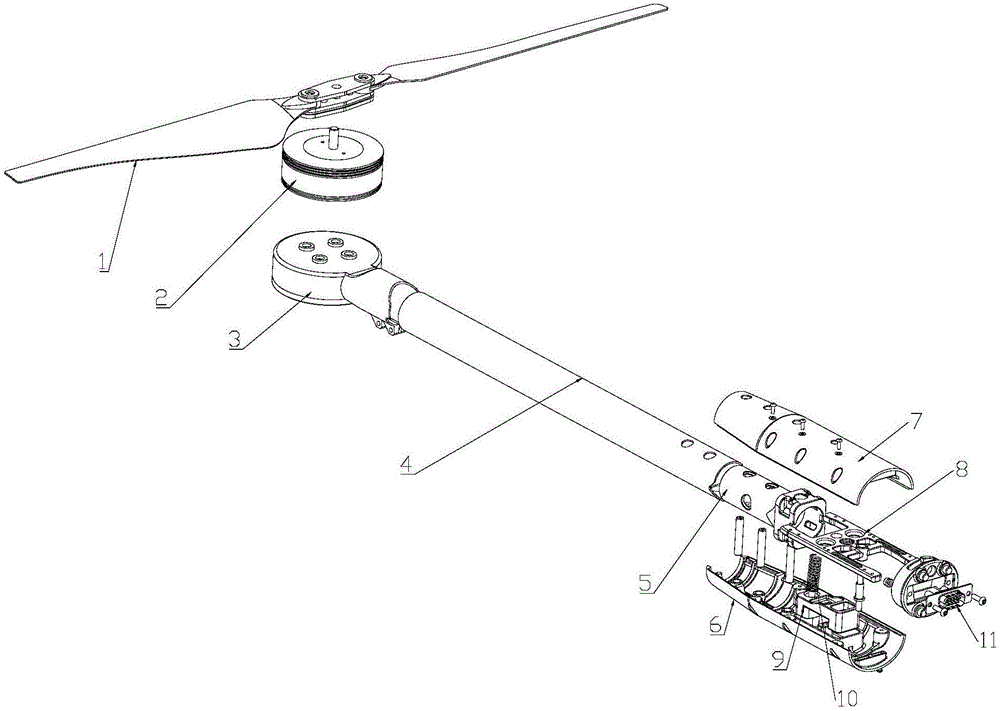

[0030] 1. Install the brushless motor 2 and the electronic speed control module 3 in a fixed position;

[0031] 2. Install with the carbon tube 4 of the paddle arm at the same time, and pass the electric wire of the electronic speed control module 3 through the carbon tube 4 of the paddle arm, and fix the electronic speed control module 3 and the carbon tube 4 of the paddle arm with the hexagon socket head screw M3×10;

[0032] 3. Pass the electronic speed control module 3 wire through the locking block 5 and the plug fixing block, and at the same time assemble the paddle arm carbon tube 4 with the locking block 5, and connect the terminal end of the electronic speed control module 3 wire to the DB9 male -39 The terminals are welded firmly one by one and waterproof;

[0033] 4. Fix the DB9 male head-39 and the plug fixing block through the hexagon socket head screw M3×10 and the non-metallic insert hexagonal locking thin nut M3;

[0034] 5. Install the fixing stud and the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com