Control device and method for plastic film packaging

A technology of a control device and a control method, which is applied in the directions of packaging, transportation and packaging, thin material processing, etc., can solve problems such as the need to improve maintainability, and achieve the goals of improving safety and reliability, strong maintainability, and improving automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

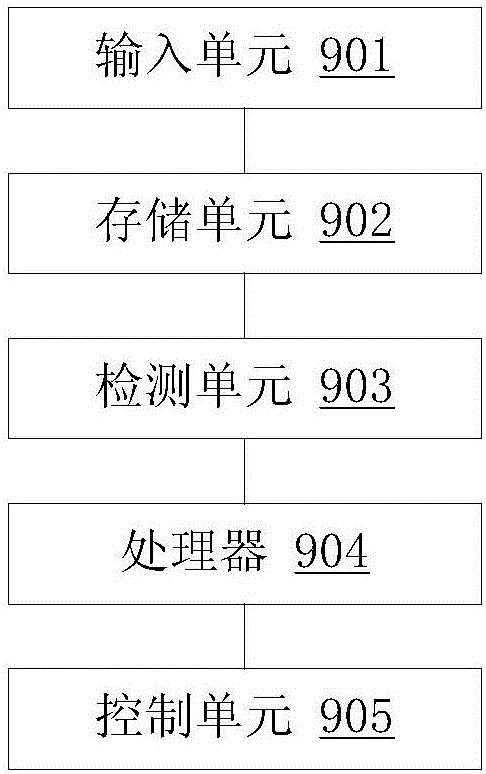

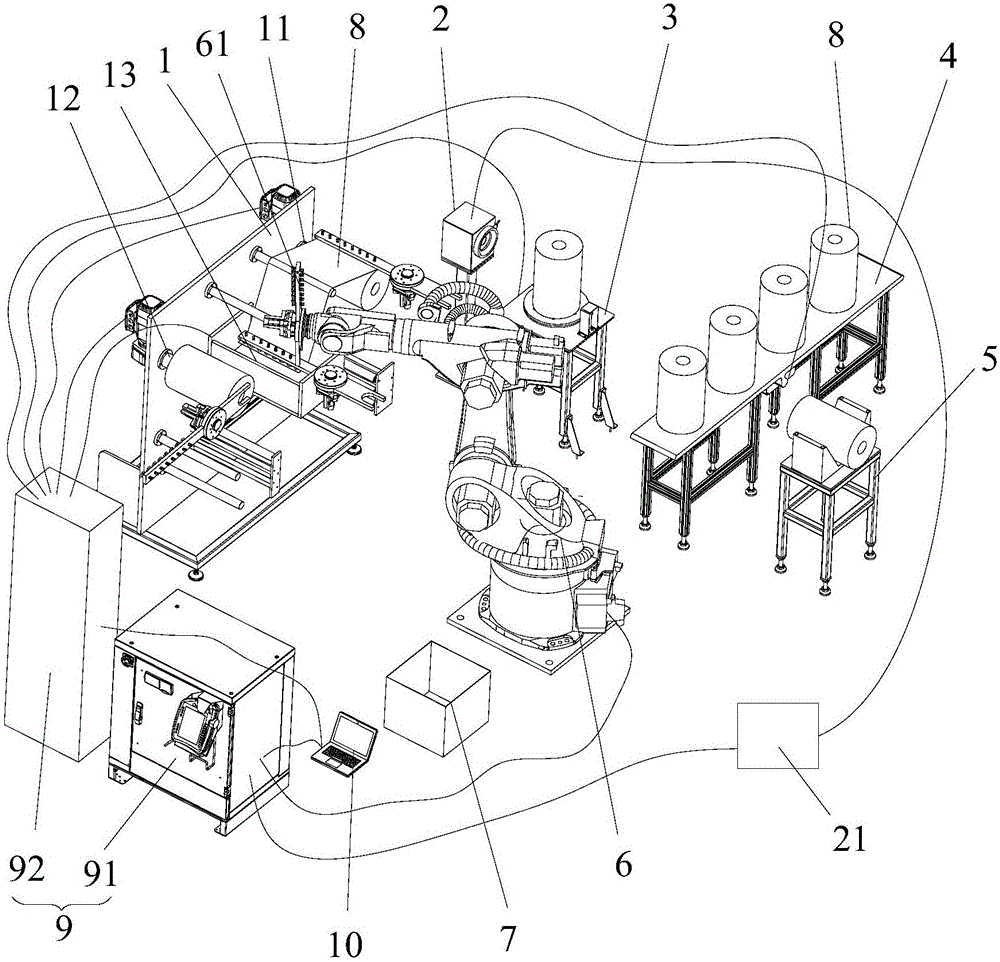

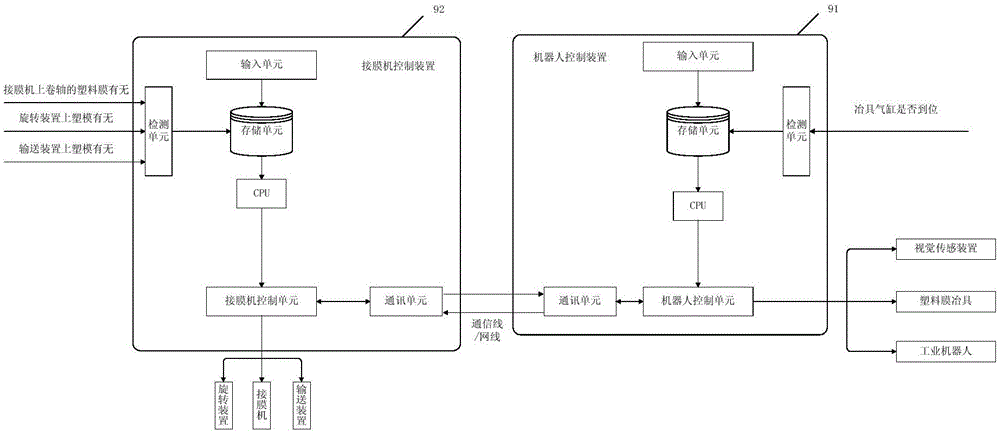

[0057]This embodiment is used for the control device of plastic film packaging, and is used to control the film splicing operation of the plastic film automatic film splicing system. Film machines and at least one industrial robot for automatically feeding rolls of plastic film to film splicers; cf. figure 1 The control device in this embodiment includes: an input unit 901 for receiving processing instructions, the processing instructions at least including the product code of the plastic film roll corresponding to the product processed by the packaging machine and a processing control program; a storage unit 902 for storing the plastic film automatically connected Preset data for film system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com