Prefabricated reinforced concrete component connecting method

A technology of reinforced concrete and connection method, which is applied in the direction of building structure and construction, and can solve problems such as difficult construction quality assurance, grouting quality assurance, and complicated construction process, so as to improve connection integrity, increase shear performance and resistance The effect of pulling performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The method for connecting prefabricated reinforced concrete members of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

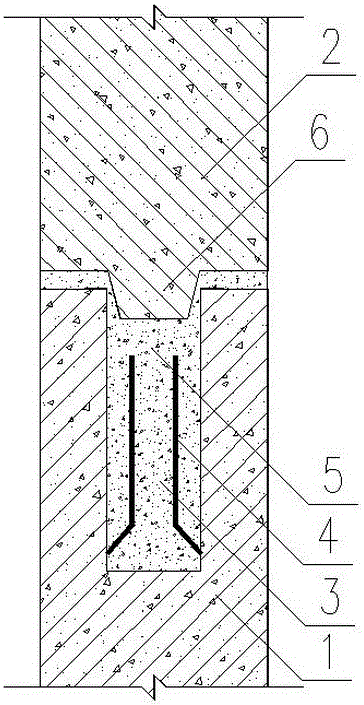

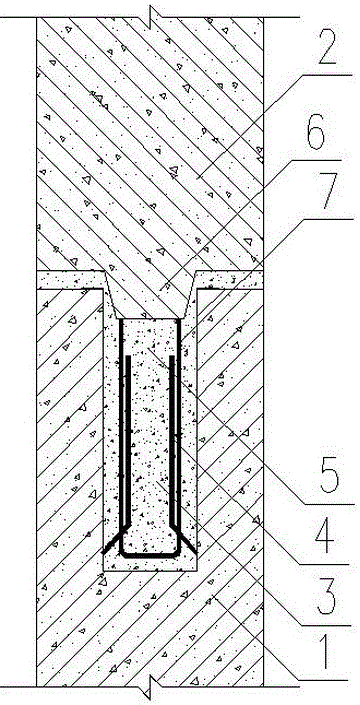

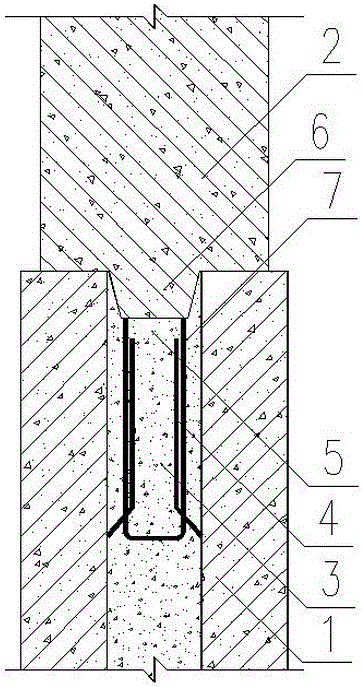

[0039] An embodiment of the method for connecting prefabricated reinforced concrete members proposed by the present invention, such as figure 1 , there is at least one hole 3 on the first prefabricated reinforced concrete member 1, and a steel bar 4 is arranged in the hole 3, and the steel bar 4 is anchored in the sidewall concrete of the hole 3; the hole 3 is filled with retarding mortar 5; the second prefabricated reinforced concrete member 2 Concrete protrusions 6 are arranged on the top; the first prefabricated reinforced concrete member 1 and the second prefabricated reinforced concrete member 2 are installed, and the upper protrusions 6 of the second prefabricated reinforced concrete member 2 extend into the hole 3; after the retarding mortar 5 hardens, the first The prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com