Multi-well Group Electromagnetic Wax Propagation Device and Method

An electromagnetic anti-wax, multi-well group technology, applied in circuits, electrical components, earth-moving drilling, etc., can solve the problems of cumbersome operation, affecting production, affecting suspended point loads, etc. good effect of wax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

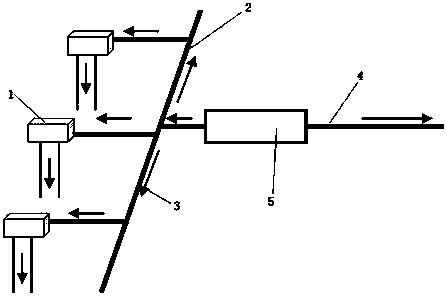

[0022] like figure 1 As shown, the multi-well group electromagnetic anti-wax propagation device includes a pipe string 2, a surface oil pipeline 4, and an electromagnetic anti-wax device 5.1. Multiple parallel production oil wells 1 are connected to one side of the pipe string 2, and one side of the pipe string 2 is connected to the ground For the oil pipeline 4, an electromagnetic anti-wax device 5.1 is installed on the surface oil pipeline 4, and the electromagnetic field propagation direction 3 propagates along the pipe string 2.

[0023] like Figure 4 As shown: the electromagnetic anti-wax device 5.1 includes a first cable plug 7, a controller 8, a second cable plug 9, an electromagnetic conversion body 10, a central tube 11, a connecting collar 12, and a power supply line 13, on the right side of the controller 8 There is a central tube 11 on the side, an electromagnetic conversion main body 10 is provided on the middle and outer side of the central tube 11, a coupling ...

Embodiment 2

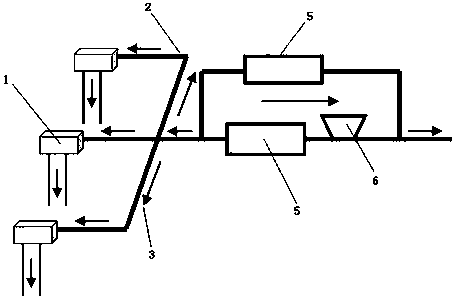

[0028] like figure 2 Shown: Different from Embodiment 1, a heating furnace 6 connected in series to the ground oil pipeline 4 is provided on the right side of the electromagnetic anti-wax device 5.1, and a spare electromagnetic device 5.1 and the heating furnace 6 are connected in parallel Anti-wax device 5.2.

Embodiment 3

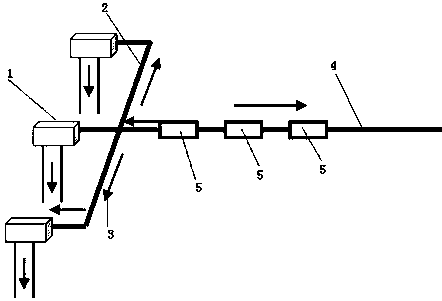

[0030] like image 3 As shown, the difference from Embodiment 1 is that a plurality of electromagnetic anti-wax devices 5.1 are connected in series on the ground oil pipeline 4, and the electromagnetic fields of the electromagnetic anti-wax devices 5.1 extend to both sides.

[0031]The propagation mechanism of the multi-well group electromagnetic anti-wax propagation device is to use the magneto-induced colloid effect and the hydrogen bond anomaly effect. The electric energy is converted into magnetic energy through the electromagnetic converter, and the electromagnetic field energy formed by the downhole tubing wall or the ground tubing wall acts on it. After the electromagnetic field acts on the fluid, it can change the molecular arrangement structure, make the disordered molecular clusters become polarized stable molecular chains, accumulate on the inner surface of the tube, and make it lose the ability to leave the solution and lie on the inner tube wall, so that Paraffin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com