Blowout and outburst preventing device and blowout and outburst preventing method for high gas outburst seam drilling, hydraulic flushing in hole and hydraulic cutting

A technology of gas outburst and outburst prevention, which is applied in the direction of gas discharge, safety devices, earthwork drilling and mining, etc. It can solve problems such as poor safety, overrun of roadway gas, complicated hole sealing, etc., and achieves convenient installation and operation, prevention of outburst accidents, The effect of short sealing casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

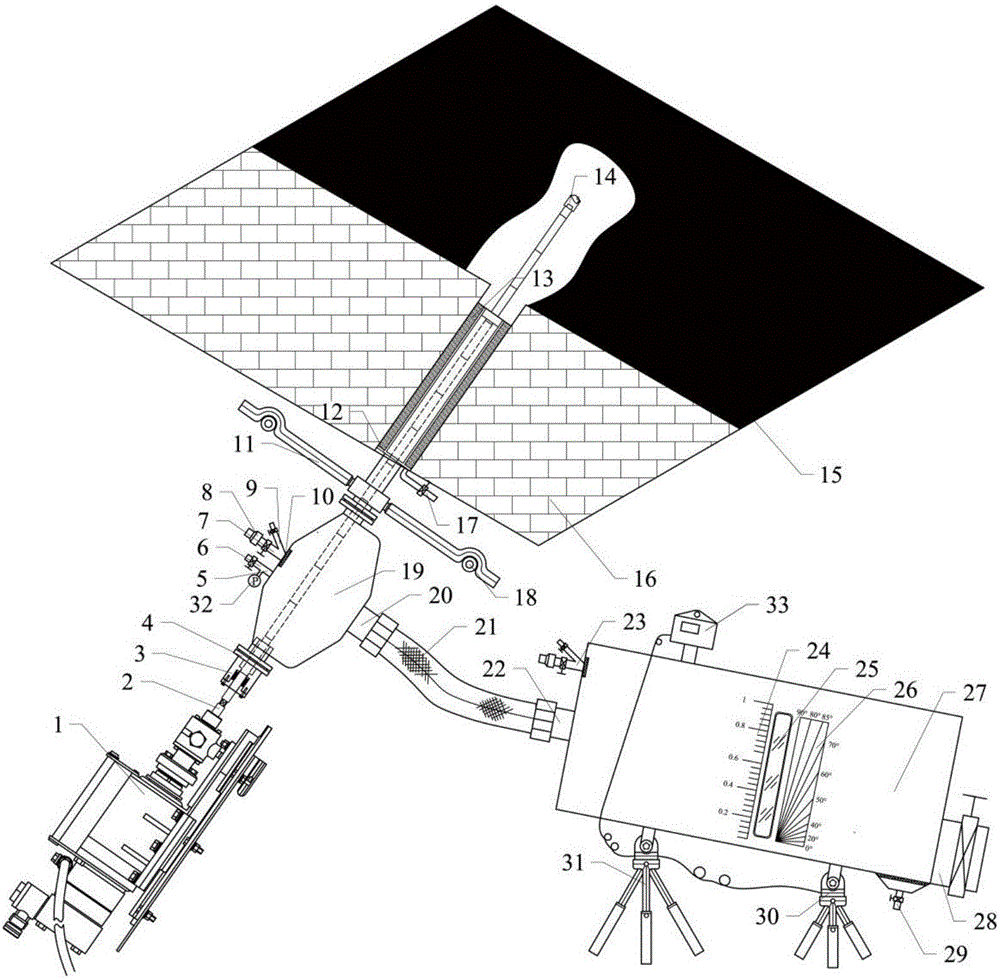

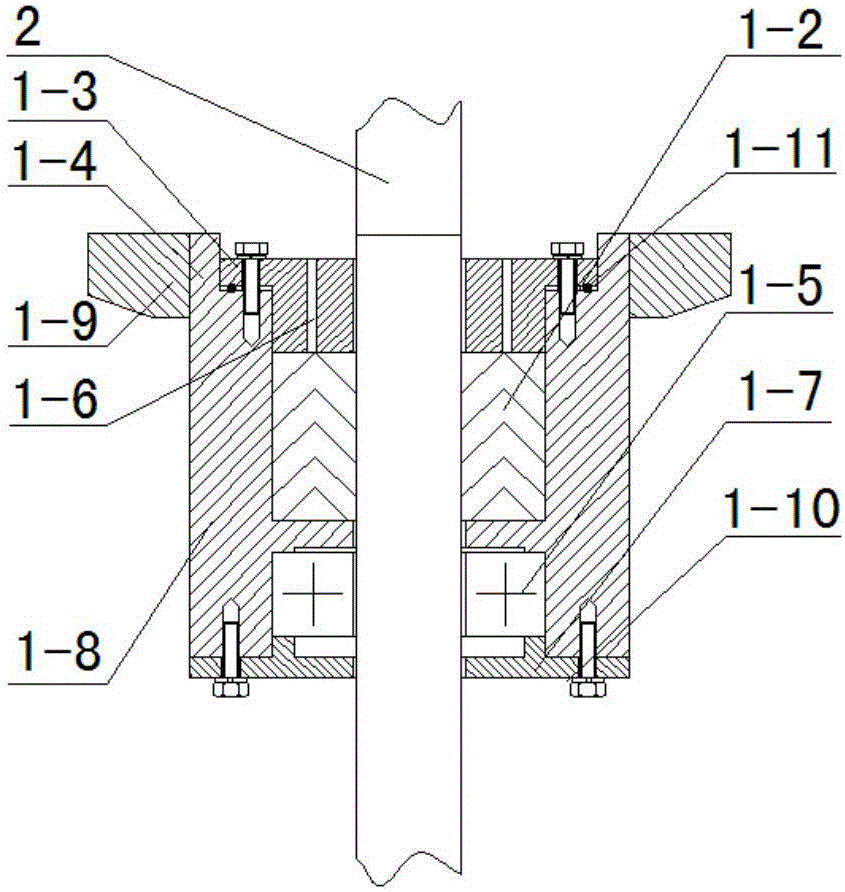

[0024] The anti-blowout and anti-outburst device includes: short casing for capsule hole sealing, air-water slag separation chamber 19, drill pipe sealing sleeve 3, air-water slag separation box 27, weighing system and anti-outburst support; One end of the water slag separation chamber 19 and the other end of the air-water slag separation chamber 19 are connected with a capsule hole-sealing short casing capable of sealing the drilled holes, and the capsule hole-sealing short casing is strengthened and fixed by anti-shock support; the air-water slag separation chamber 19 is connected to the air-water slag separation box 27 through a high-strength spring hose, the air-water slag separation box 27 is installed on the weighing system, the drill pipe 2 runs through the drill pipe sealing sleeve 3, the air-water slag separation box 27 and the capsule hole sealing short Casing up to the borehole.

[0025] The gas-water slag separation chamber 19 has a separation chamber, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com