A Closed Hydraulic System with Multiple and Single Piston Pumps Recombined to Control Asymmetric Hydraulic Cylinders

A hydraulic system and hydraulic cylinder technology, applied in the field of hydraulic cylinder control, can solve the problems of increasing the complexity and design difficulty of the hydraulic system, and achieve the effects of simple structure, high reliability, and elimination of flow and pressure output pulsation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments.

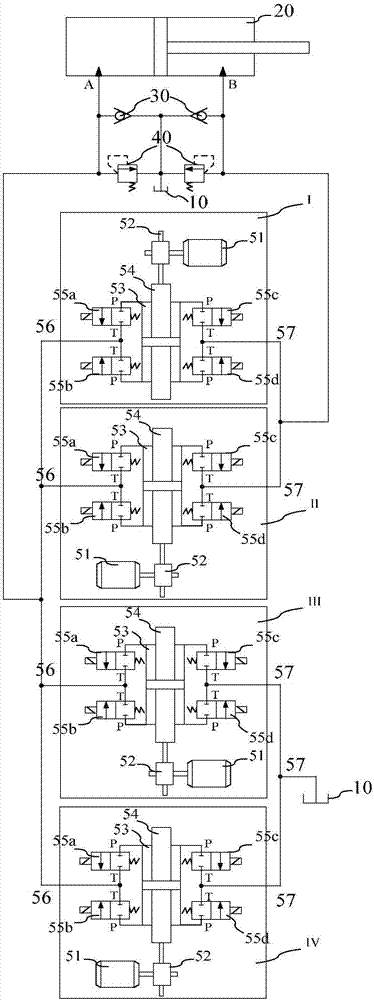

[0020] refer to figure 1 , a closed hydraulic system in which multiple single-piston pumps are recombined to control an asymmetric hydraulic cylinder, including a fuel tank 10 and a hydraulic cylinder 20, the hydraulic cylinder 20 is an asymmetric hydraulic cylinder, which is provided with a large cavity oil port A and a small cavity oil mouth B. It also includes two one-way valves 30, two safety valves 40 and multiple sets of single plunger pumps. The first oil inlet and outlet ports 56 of the multiple groups of single plunger pumps are all connected with the large cavity oil port A, wherein the second oil inlet and outlet ports 57 of at least two groups of single plunger pumps are connected with the small cavity oil port B, and the remaining groups The second oil inlet and outlet port 57 of the single plunger pump communicates with the oil tank 10 to compensate the flow difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com