A polysiloxane with high-efficiency self-healing properties and its preparation method

A technology of polysiloxane and hydroxypolysiloxane, which is applied in the chemical field, can solve the problems of low self-repair rate and achieve the effect of promoting repair, improving mechanical properties, improving migration and movement characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

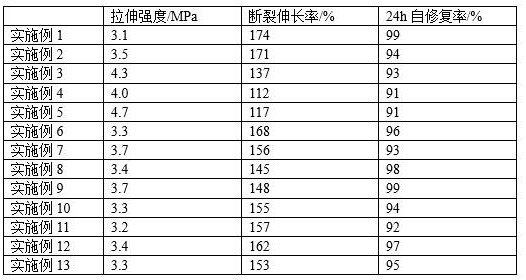

Examples

Embodiment 1

[0030] Weigh 5 g of pyridine-4-boronic acid and 60 g of white carbon black in a ball mill jar, and ball mill for 20 h at room temperature to obtain a white solid powder.

[0031] Mix the above powder with 200g polydimethylsiloxane disilanol (M n ~24KDa) was put into the internal mixer and mixed for 20 minutes to obtain a white powdery solid. The obtained solid was placed in an aluminum pan, and then heated to 160° C. in an oven for 4 hours to obtain a white hard solid. The obtained solid can be molded by heating (130°C, 12MPa).

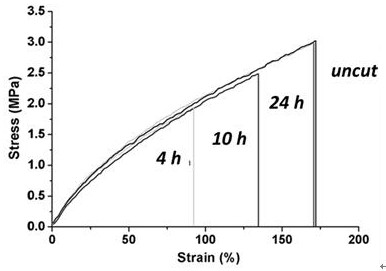

[0032] The self-healing curve of the obtained polysiloxane sample is as follows figure 1 shown. It can be seen that the strength of the cut sample reached 99% of the original sample after 24h room temperature repair.

Embodiment 2

[0034] Weigh 5g of 4-(N,N’-dimethylamino)-phenylboronic acid and dissolve it in 20mL of tetrahydrofuran, then stir and mix with 200g of polydimethylsiloxane disilanol (Mn~24KDa). After mixing, THF was removed under reduced pressure, and the resulting clear liquid was mixed with 60 g

[0035] White carbon black was added into the internal mixer and mixed for 20 minutes to obtain a white powdery solid. The obtained solid was placed in an aluminum pan, and then heated to 160° C. in an oven for 4 hours to obtain a hard purple solid. The obtained solid can be molded by heating (130°C, 12MPa).

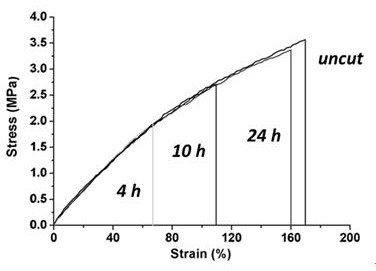

[0036] The self-healing curve of the obtained polysiloxane sample is as follows figure 2 shown. It can be seen that the strength of the cut sample reached 94% of the original sample after 24h room temperature repair.

Embodiment 3

[0038] Weigh 5g of 4-(N,N')-dimethylamino-phenylboronic acid and dissolve it in 20mL of tetrahydrofuran, then mix with 200g of poly(dimethyl-co-methylphenyl)siloxane disilanol (Mn~13KDa, 20%wt of phenyl) stirred and mixed evenly. After mixing, the tetrahydrofuran was removed under reduced pressure, and the obtained clear liquid and 60 g of white carbon black were added to an internal mixer and mixed for 20 minutes to obtain a white powdery solid. The obtained solid was placed in an aluminum pan, and then heated to 160° C. in an oven for 4 hours to obtain a hard purple solid. The obtained solid can be shaped by heating and pressing (150°C, 12MPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com