Ball screw and motor integrated driving electric cylinder

A ball screw and drive electric cylinder technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the installation size of the width of the electric cylinder and low response speed, so as to optimize the installation size, eliminate transmission errors and delay Time, the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

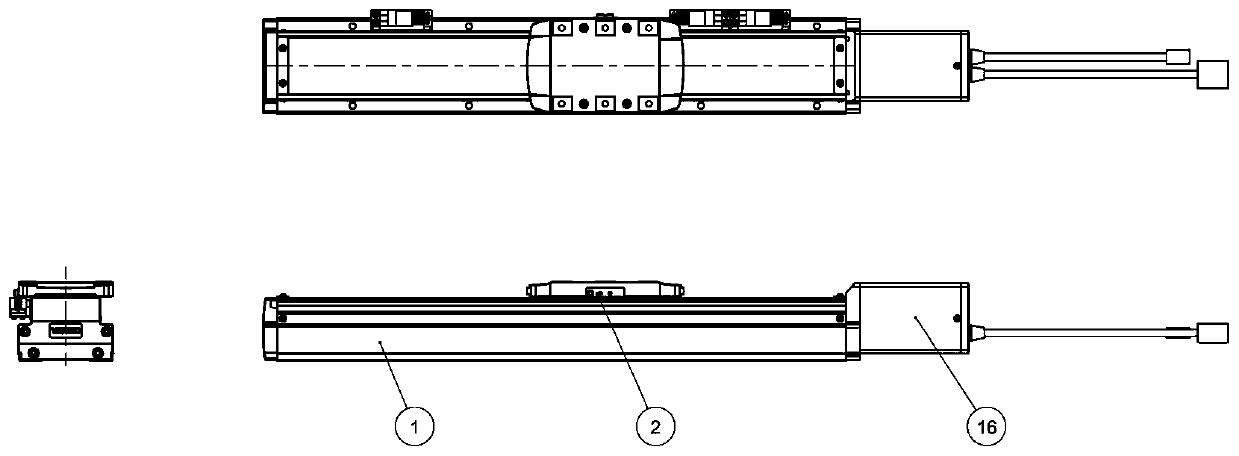

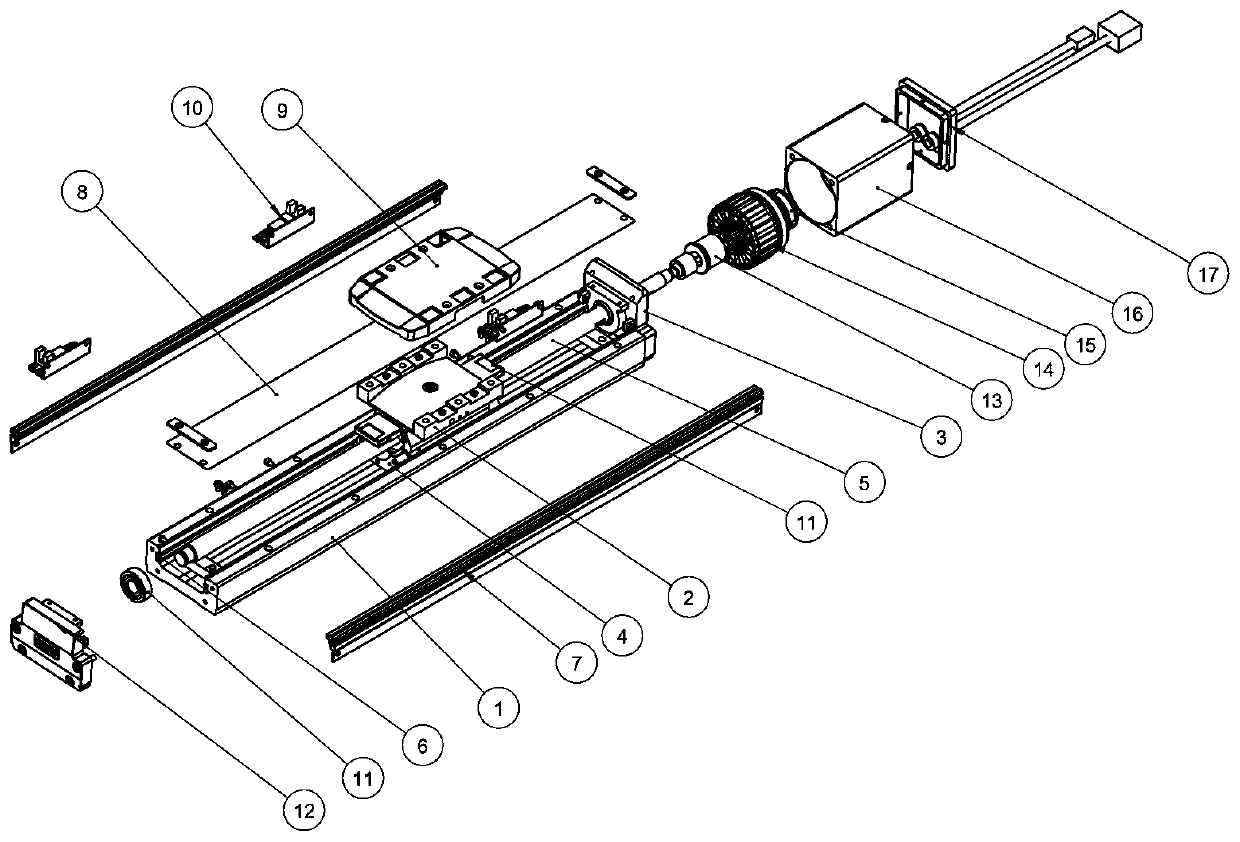

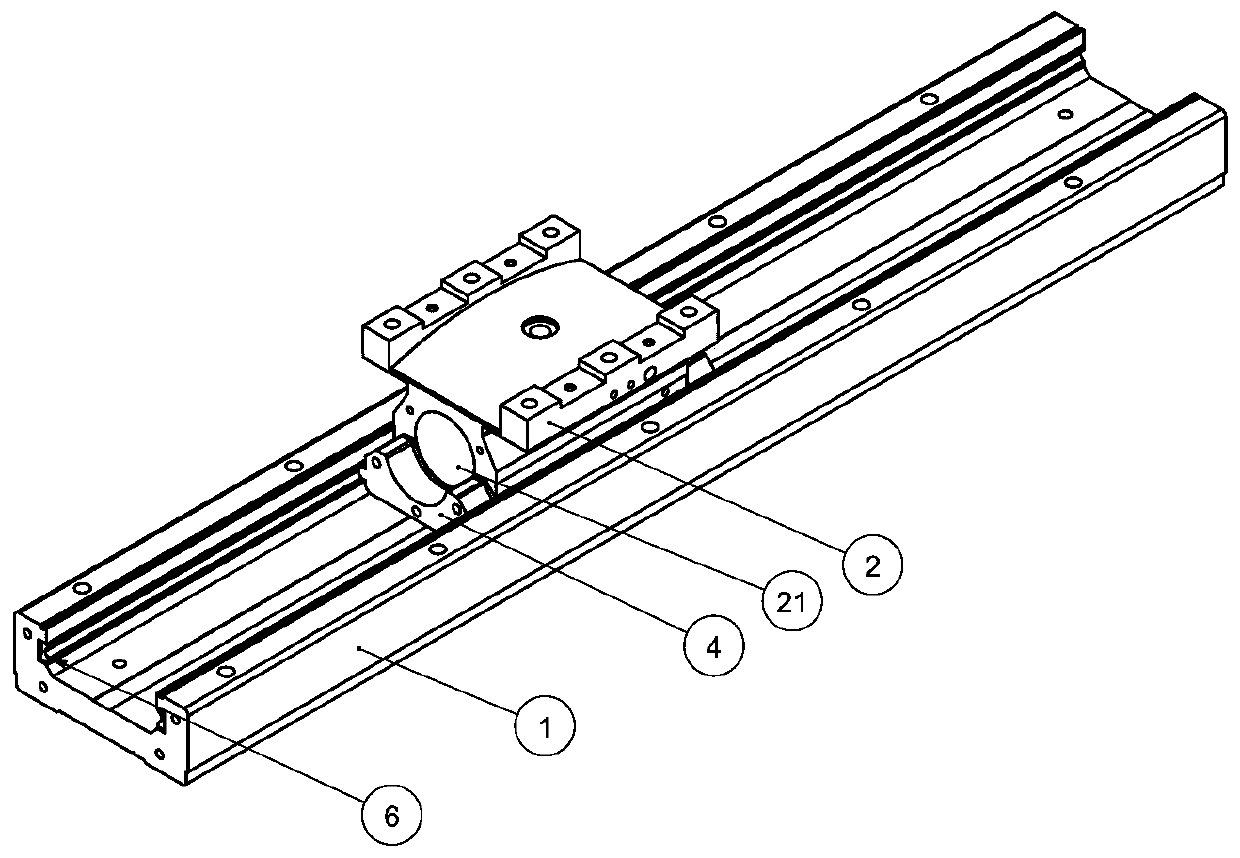

[0026] refer to Figure 1-4 , a driving electric cylinder integrated with a ball screw and a motor, including a linear guide part, a slide seat 2 and a servo motor structure, the linear guide part is embedded with an embedded guide rail structure, and a screw is provided on one side of the slide seat 2 Nut installation hole 21, ball screw nut is installed in the screw nut installation hole 21, ball screw nut is installed with ball screw 5 by steel ball rolling, and the two ends of ball screw 5 all extend to the screw nut installation hole 21, the servo motor structure includes a servo motor mover mandrel 13 installed on the 5 shaft ends of the ball screw.

[0027] In the present invention, the linear guide part is composed of a base 1 and a sliding seat 2 with an embedded guide rail structure. Steel balls are rolled on the base 1 and the sliding seat 2. Precision movement.

[0028] In the present invention, the cross-section shape of the base 1 with the embedded guide rail s...

Embodiment 2

[0037] refer to Figure 1-4 , a driving electric cylinder integrated with a ball screw and a motor, including a linear guide part, a slide seat 2 and a servo motor structure, the linear guide part is embedded with an embedded guide rail structure, and a screw is provided on one side of the slide seat 2 Nut installation hole 21, ball screw nut installation hole 21 is installed with ball screw nut ball screw nut is installed with ball screw 5 through steel ball rolling, and the two ends of ball screw 5 all extend to screw nut installation hole 21 In addition, the servo motor structure includes a servo motor mover mandrel 13 installed on the shaft end of the ball screw 5.

[0038] In the present invention, the linear guide part is composed of a base 1 and a sliding seat 2 with an embedded guide rail structure. Steel balls are rolled on the base 1 and the sliding seat 2. The steel balls are high-precision, high-hardness steel balls.

[0039] In the present invention, the cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com