Special check valve of safety level 3 for passive medium-pressure safety injection system

A passive, check valve technology, applied in the direction of safety valve, functional valve type, lift valve, etc., can solve the problem of inability to guarantee long-term continuous use of the product, and achieve the effect of eliminating sealing difficulties, facilitating sealing and reducing flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

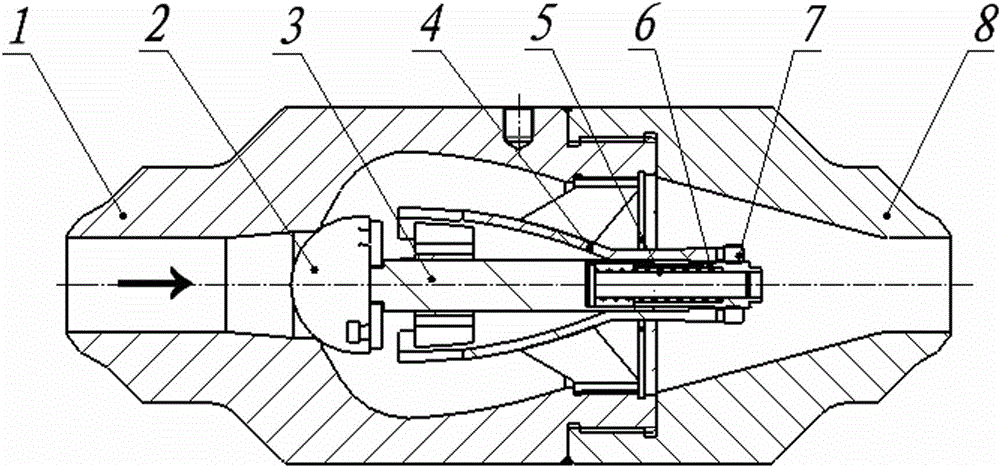

[0029] 1) The special safety level 3 non-return valve for the passive medium pressure safety injection system, including the first valve body 1, the second valve body 8, the shroud assembly 4, the spring 5, the adjusting screw 6, the lock nut 7, the spherical Spool 2, valve stem 3. The first valve body 1 is provided with an inlet cavity, and the second valve body 8 is provided with an outlet cavity. The first valve body 1 and the second valve body 8 are fixedly connected by threads to form a valve body, and the inner cavity of the valve body is dome-shaped. , forming an annular streamlined channel with the shroud group and the valve core group, which improves the flow capacity and reduces the flow resistance. The valve body constitutes an axial flow structure (also called a pipeline structure), and the shroud assembly 4 is arranged in the valve body. The spherical valve core 2 is tightly matched with the valve seat of the inlet cavity, the spherical valve core 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com