Automatic bullet conveying device for mortar

A technology for mortar and bomb feeding, which is applied in the field of automatic mortar feeding devices, and can solve problems such as the failure to fully guarantee the reliability and stability of bomb feeding, the lack of symmetry in the overall structure of the manipulator, and the large trajectory error at the end of the manipulator, etc. problems, to achieve the effect of increasing redundant insurance, reducing assembly complexity, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

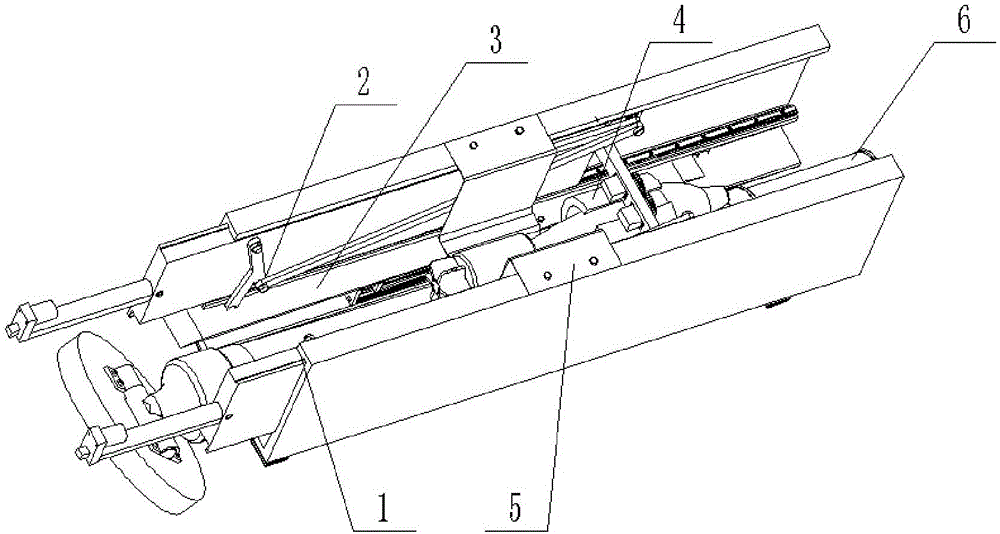

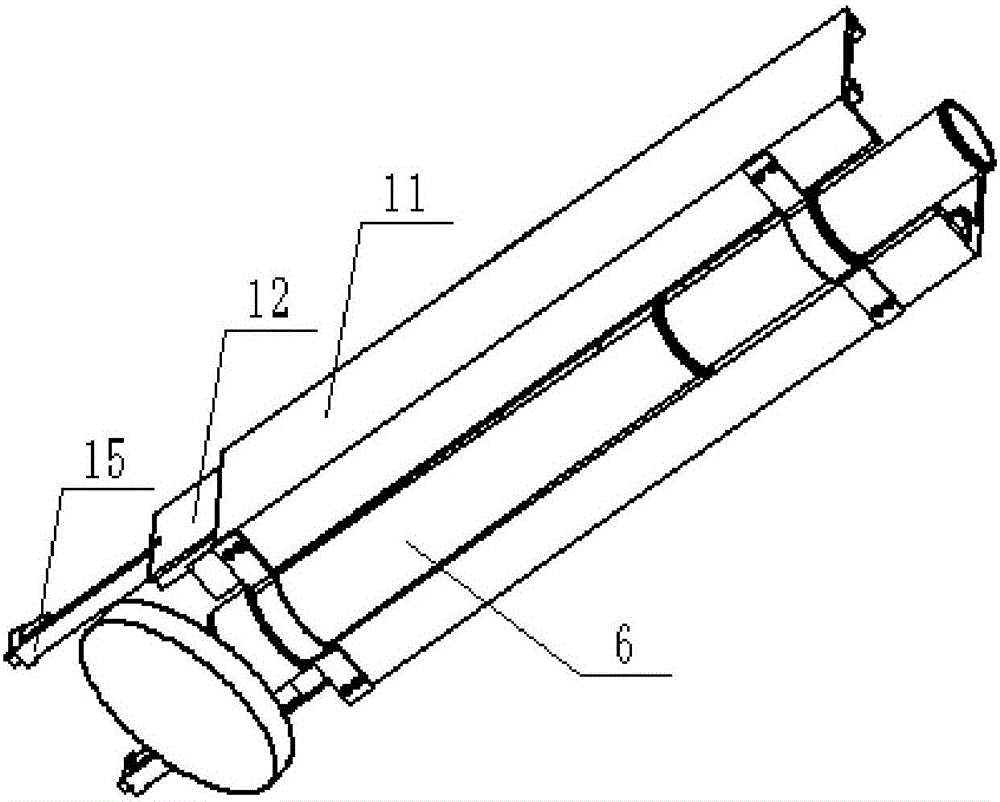

[0027] Such as figure 1 , 2 As shown, the mortar automatic feeding device of the present invention is detachably mounted on the mortar barrel 6, and includes a guide rail system 1, a plane four-bar linkage mechanism 2, a screw slide mechanism 3, and a clamping mechanism 4 and tray 5;

[0028] The clamping mechanism 4 is used to clamp the shells placed on the tray 5, and under the joint action of the planar four-bar linkage mechanism 2 and the screw slide mechanism 3, the shells are sent into the mortar barrel along the rail system 1 within 6.

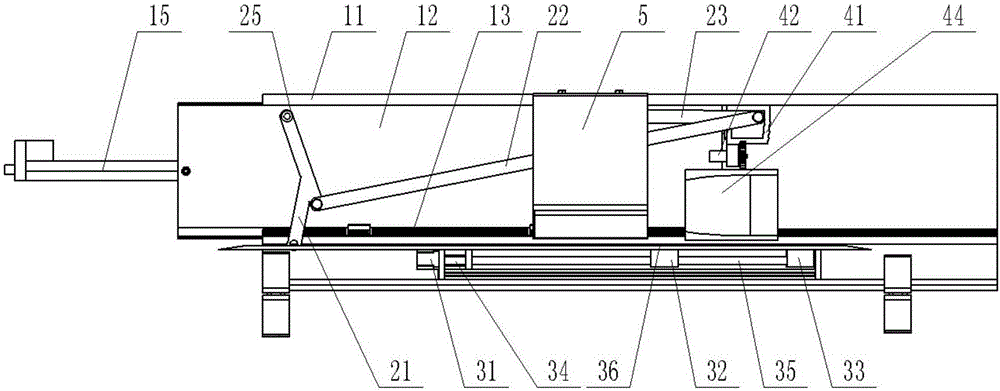

[0029] Such as image 3 , 4 As shown, the guide rail system 1 includes fixed guide rails 11, movable guide rails 12, linear guide rails 13 and optical axis guide rails 14 arranged in pairs relative to the mortar barrel 6, and the cross section of the fixed guide rails 11 is "E" shaped , the openings of the two fixed guide rails 11 are facing each other, the linear guide rail 13 is elongated and fixed on the middle step of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com