Automatic digital display multi-directional pressure vessel angle measuring device

A technology of pressure vessel and measuring device, applied in the direction of angle/taper measurement, etc., can solve the problem of limited accuracy and low accuracy, and achieve the effect of enhancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

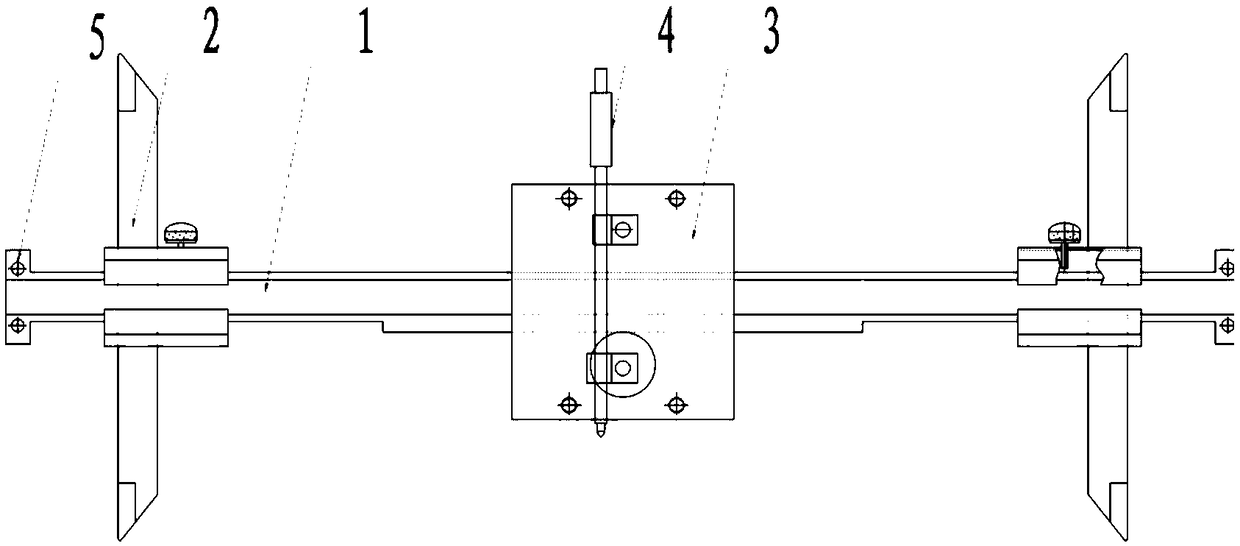

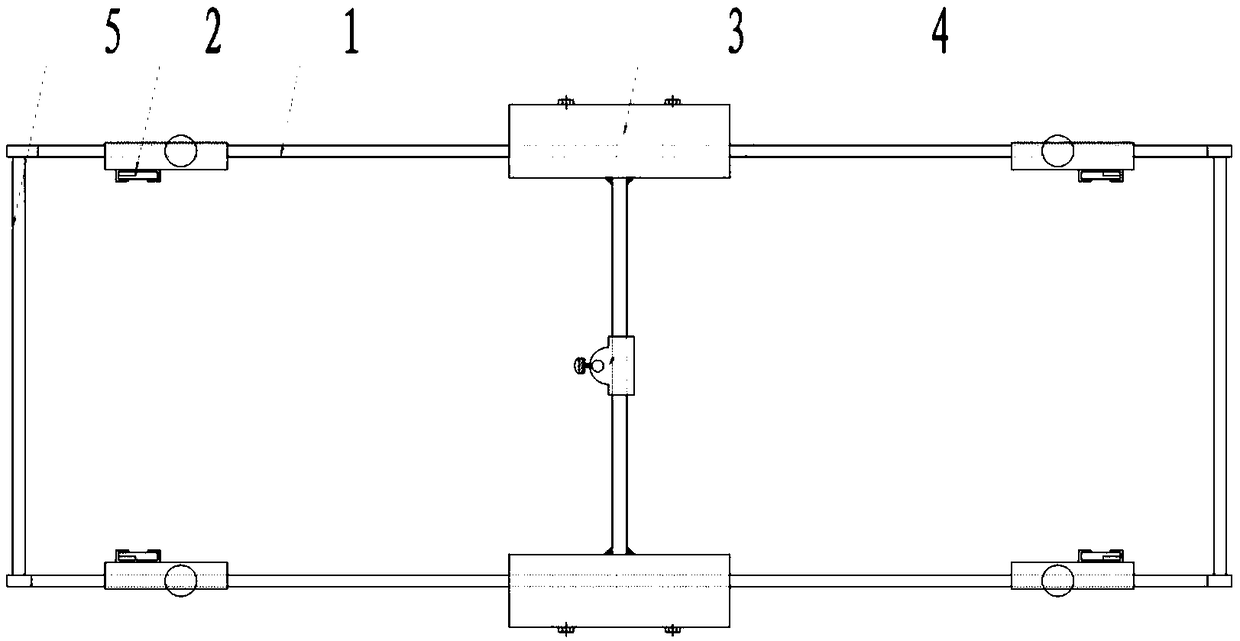

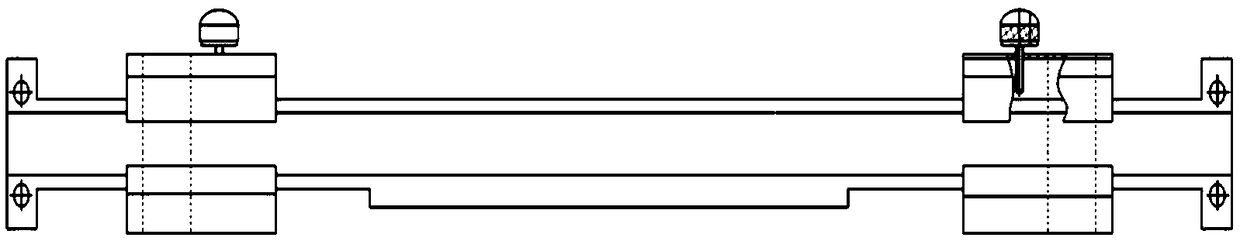

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to Figure 1 to Figure 9 , an automatic digital display multi-directional pressure vessel edge angle measuring device, comprising a bracket, a contact probe digital display component 4 and a sliding foot stand 2 that can be retracted up and down, and the sliding foot stand 2 is symmetrically arranged on the support in pairs, Both ends of the contact probe digital display assembly 4 are installed in the sliding box 3, and the sliding box 3 can be horizontally slidably set on the bracket, and the contact probe digital display assembly 4 is located on two sliding legs. between racks;

[0032] The contact probe digital display assembly 4 includes a dial gauge probe and a digital display device, the digital display device is installed on the upper end of the dial gauge probe, and the dial gauge probe is fixedly connected with a slide block, and the slide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com