Electrostrictive micromotion structure for improving two-axis rotating table tracking precision and control method thereof

A two-axis turntable and tracking accuracy technology, applied in the direction of using feedback control, etc., can solve the problems of difficult operation, limited by the friction of mechanical parts, and difficult to greatly improve the accuracy. The method is simple and easy to achieve, avoiding adverse effects , Precision adjustment and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

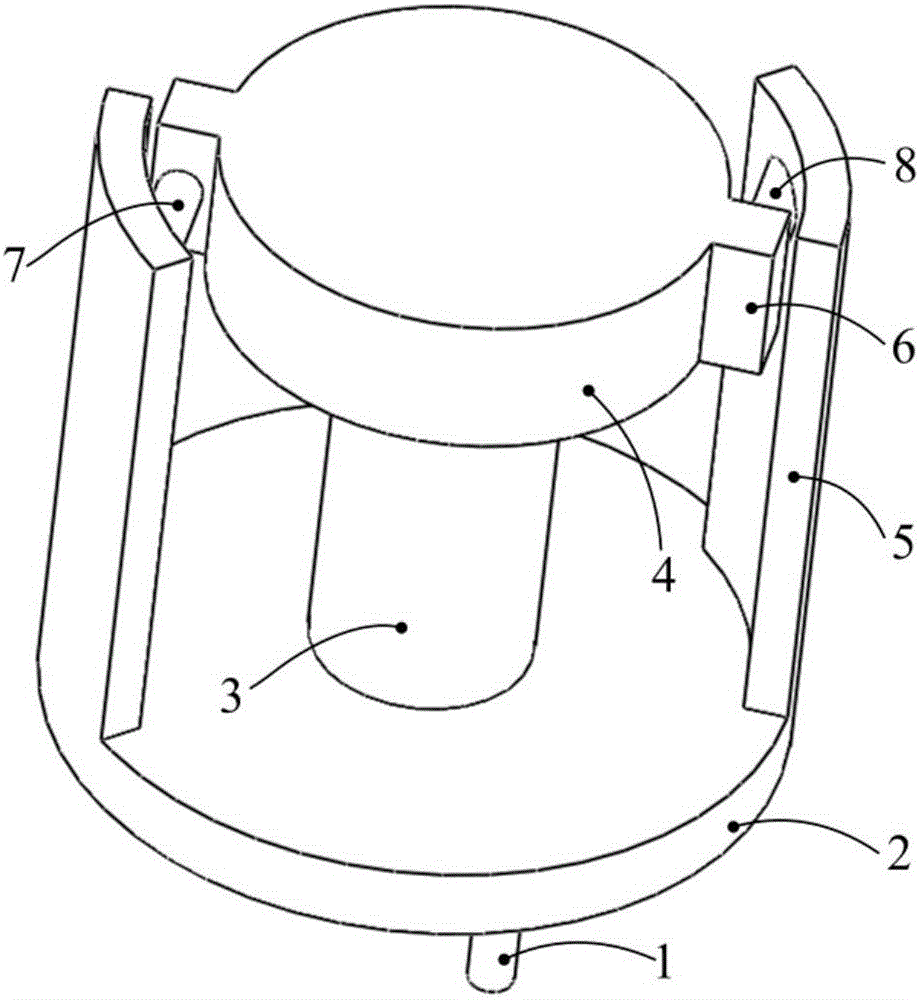

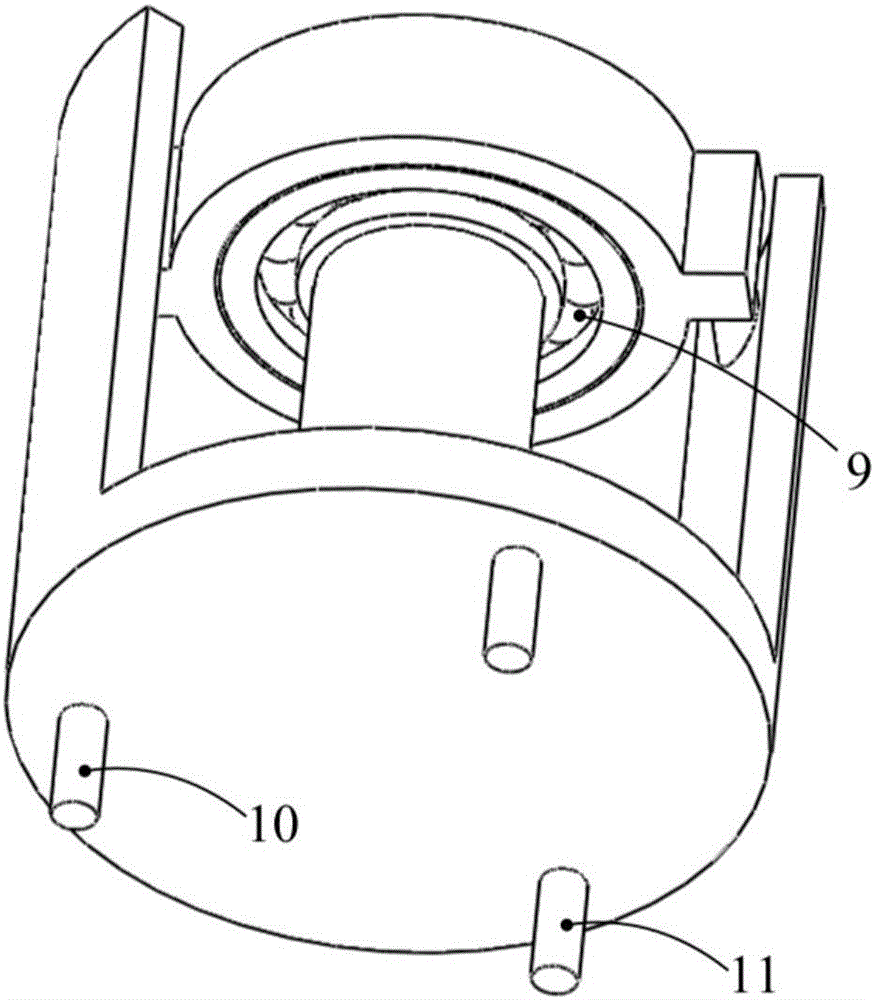

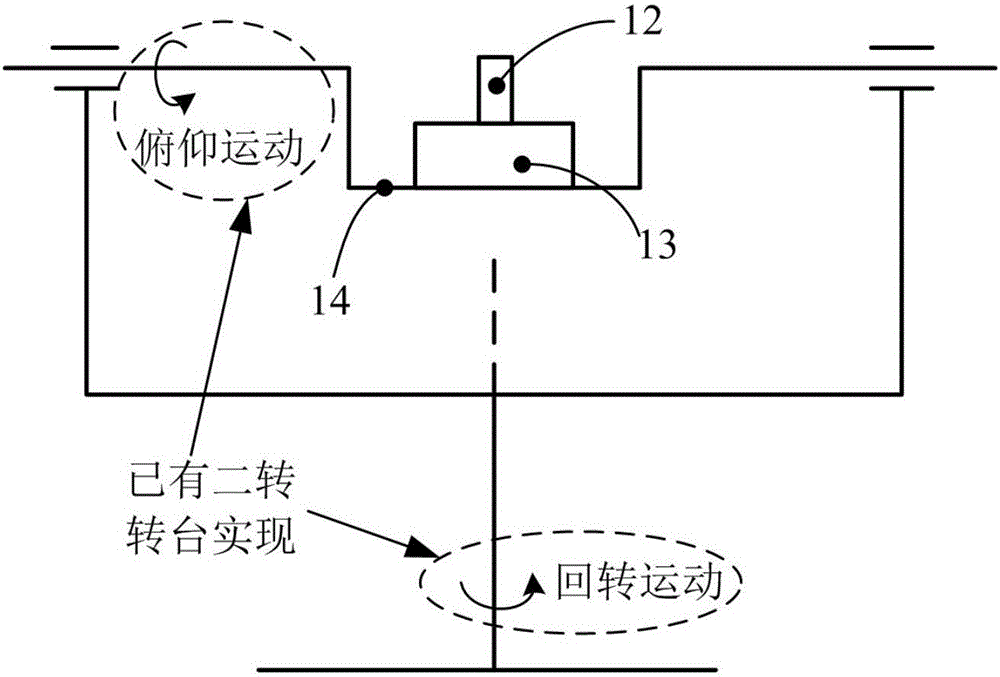

[0037] Such as figure 1 and 2 As shown, it is the electrostrictive fretting structure described in the present invention. The electrostrictive fretting structure includes two layers of circular bases: the first layer of pitching base 2 and the second layer of rotating base 4, three electrostrictive The telescopic elements 1, 10, 11 are evenly installed under the pitch base 2 as pitch electrostrictive elements, the other end of the telescopic elements is connected with the existing two-axis turntable, and the two electrostrictive elements 7 and 8 are used as rotating electrostrictive elements. The element is installed on the bosses 6 at both ends of the diameter of the rotary base 4, and one end of the telescopic element is fixed on the arc-shaped mounting plate 5, and the central axis of the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com