Apparatus and method for reverse osmosis

A reverse osmosis device and reverse osmosis technology, applied in chemical instruments and methods, reverse osmosis, osmosis/dialysis water/sewage treatment, etc., can solve the problems of low yield, high pressure, and high specific energy consumption of drinking water products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

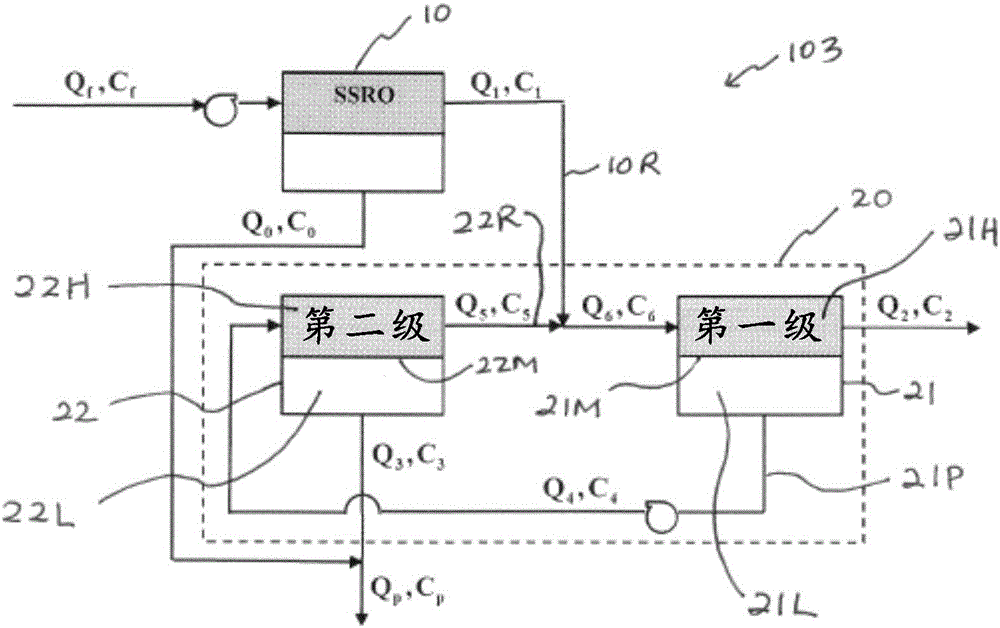

[0038] The following reference Figure 1 to Figure 6, an exemplary embodiment of an energy-efficient reverse osmosis (EERO) process of the present invention is described, and the same reference numerals are used in each drawing to refer to the same or similar components.

[0039] Such as figure 1 As shown, in the first embodiment 103 of the EERO plant and process of the present invention, the high pressure retentate 10R of the SSRO stage 10 is fed to a counterflow membrane cascade CMCR unit 20 having two stages 21, 22, while the filtrate 21P The high pressure (retentate) side 22H of the second stage 22 is then recirculated from the first stage 21 . Since this embodiment is a hybrid configuration of one SSRO stage 10 and two stages 21 , 22 of CMCR units 20, it will be referred to hereinafter as the three-stage embodiment 103 of the EERO.

[0040] The SSRO stage 10 includes one or more reverse osmosis modules (not shown) connected in parallel. In the CMCR unit 20, each of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

| desalination ratio | aaaaa | aaaaa |

| degrees of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com