Multi-layered shaped body for internal vehicle fittings and method for producing such shaped bodies

A technology for molded bodies and internal accessories, applied in vehicle parts, household components, applications, etc., can solve problems such as changes in the properties of covering materials, insufficient joint fixing of covering materials, and slippage, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

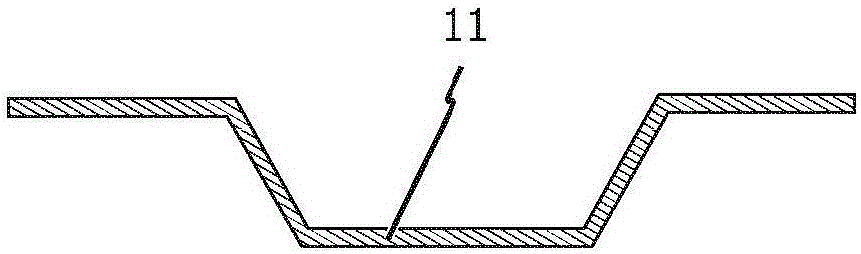

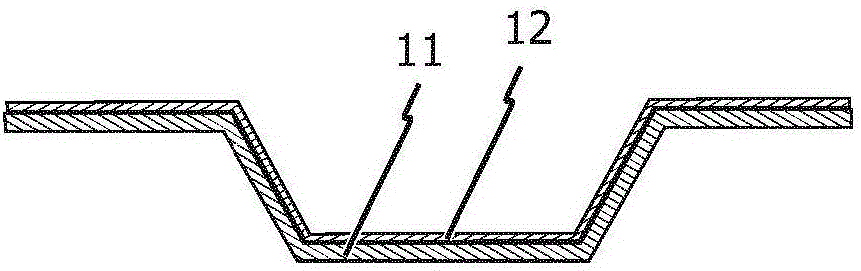

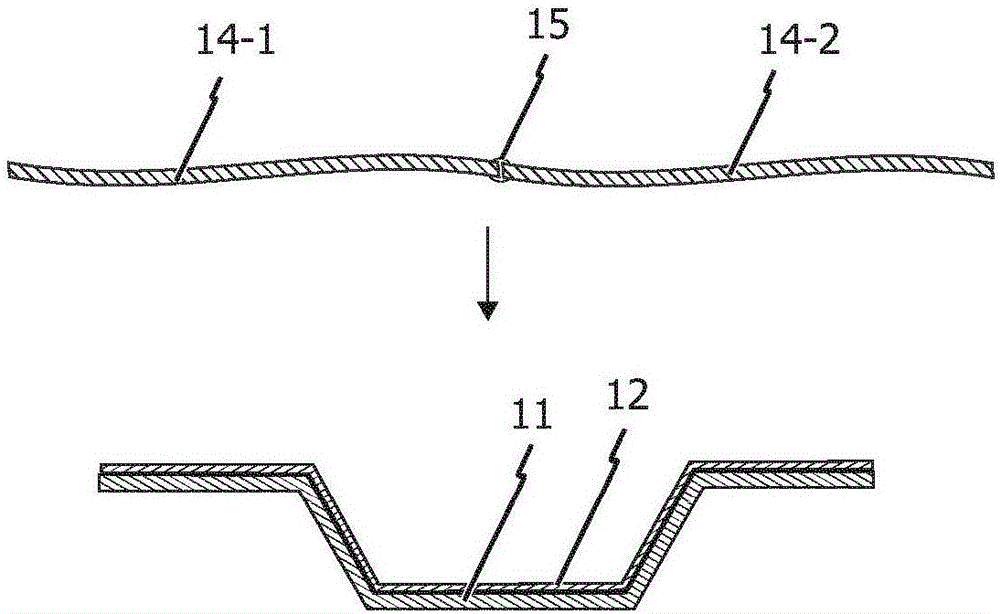

[0055] Figures 1a to 1e A first example of the method according to the invention for producing a multilayer molded body is shown. Such as Figure 1a In particular, a self-supporting barrier layer 11 impermeable to foamed plastic, such as polyurethane foam, is first produced according to this example. The barrier layer 11 can thereby be formed, for example, from a foamed polyolefin or polystyrene film. As mentioned above, the self-supporting barrier layer 11 exhibits a specific shape corresponding to the outer contour of the molded body to be produced, as will be explained in more detail below. The molded body can be, for example, the outer contour of a dashboard, a door trim panel, a center console or other similar interior parts for a motor vehicle. In other words, the self-supporting barrier layer 11 is preformed before being introduced into the foam mould.

[0056] This preforming is performed, for example, by deep drawing the aforementioned polyolefin or polystyrene fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com