Protective airbag with rapid gas generating device

A production device and fast technology, applied in protective clothing, clothing, apparel, etc., can solve the problems of inappropriate human wearable equipment, gas leakage, large volume, etc., to improve comfort and convenience, poor invisibility, and large volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

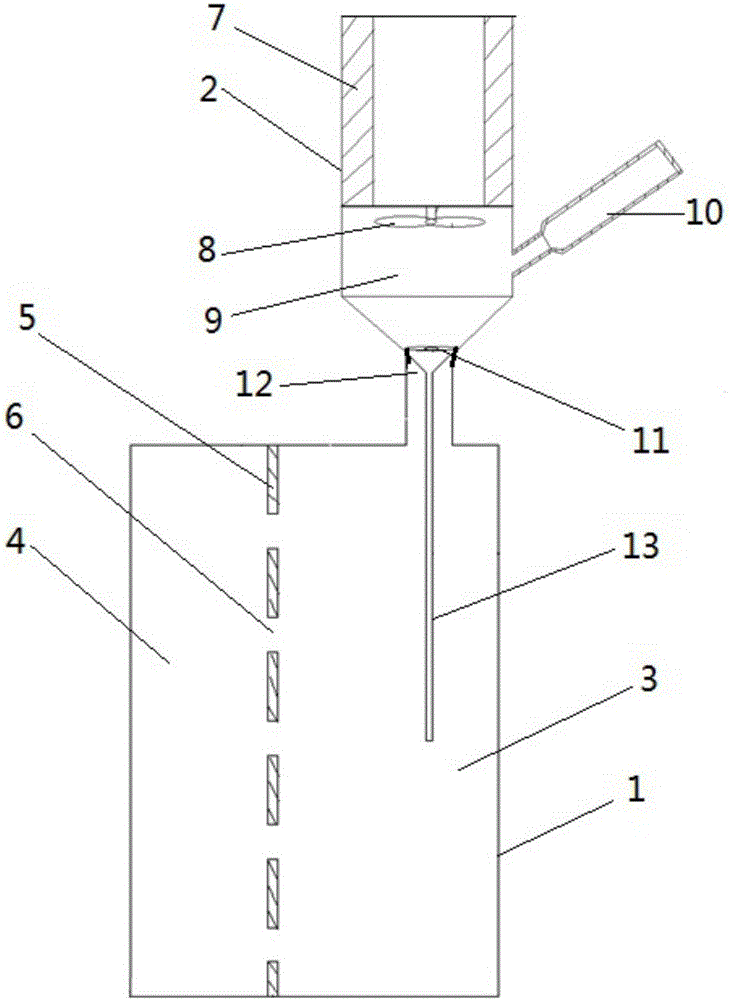

[0010] As shown in the figure, the protective airbag of the band gas rapid generation device comprises an air bag 1 and a gas rapid generation device 2 communicated with the air bag; Air pressure buffer zone 4, sodium bicarbonate powder is placed in the main protection area 3, air guide holes 6 are arranged on the separation layer, and a gas rapid generation device 2 is connected outside the air inlet. The gas rapid generation device includes a shell 7 and is installed on A propeller 8 driven by a motor in the middle of the shell, a conical bottom cavity 9 located below the propeller, a liquid storage bag 10 connected to the conical bottom cavity, and aluminum sulfate solution is placed in the liquid storage bag 10, and the conical bottom cavity The bottom end of the valve is provided with a one-way valve type liquid outlet 11, and the liquid outlet 11 is connected with the liquid inlet 12 of the air bag. A liquid inlet pipe 13 can be inserted into the main protected area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com