Corn kernel quality vision detector

A visual inspection device and technology for grains, which are applied in sorting and other directions, can solve the problems of difficulty in realizing automatic tiling and distribution, lack of automatic inspection devices for corn kernel quality inspection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail and complete below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

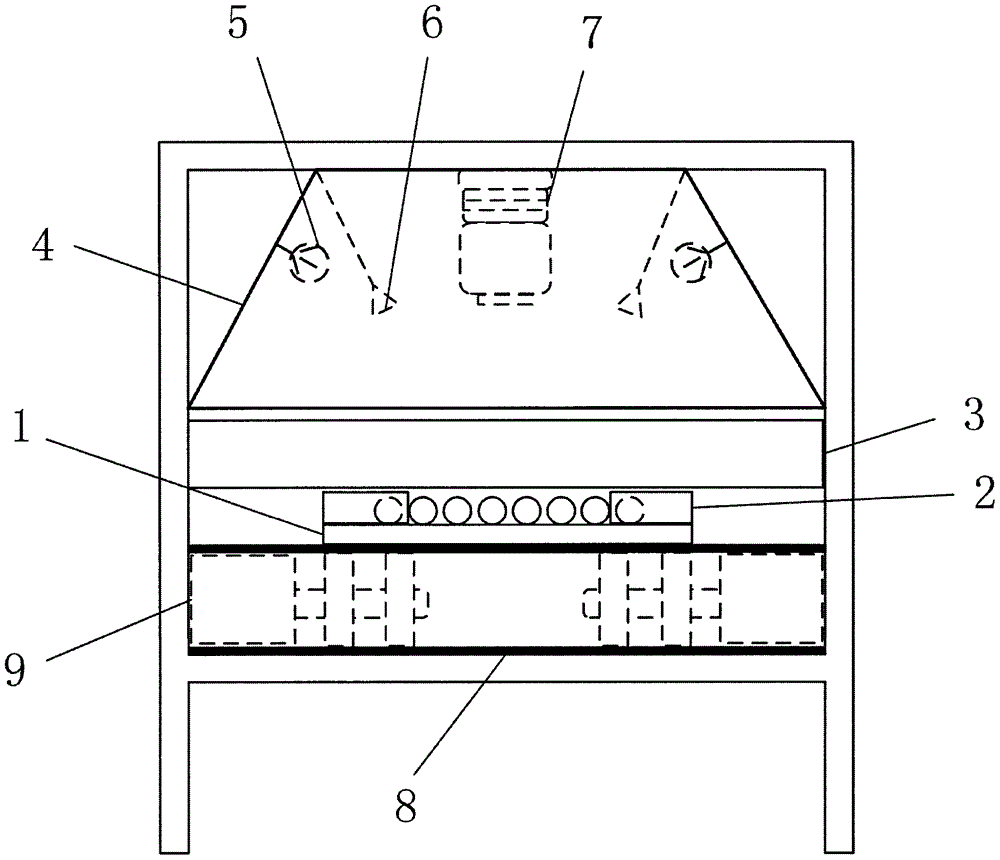

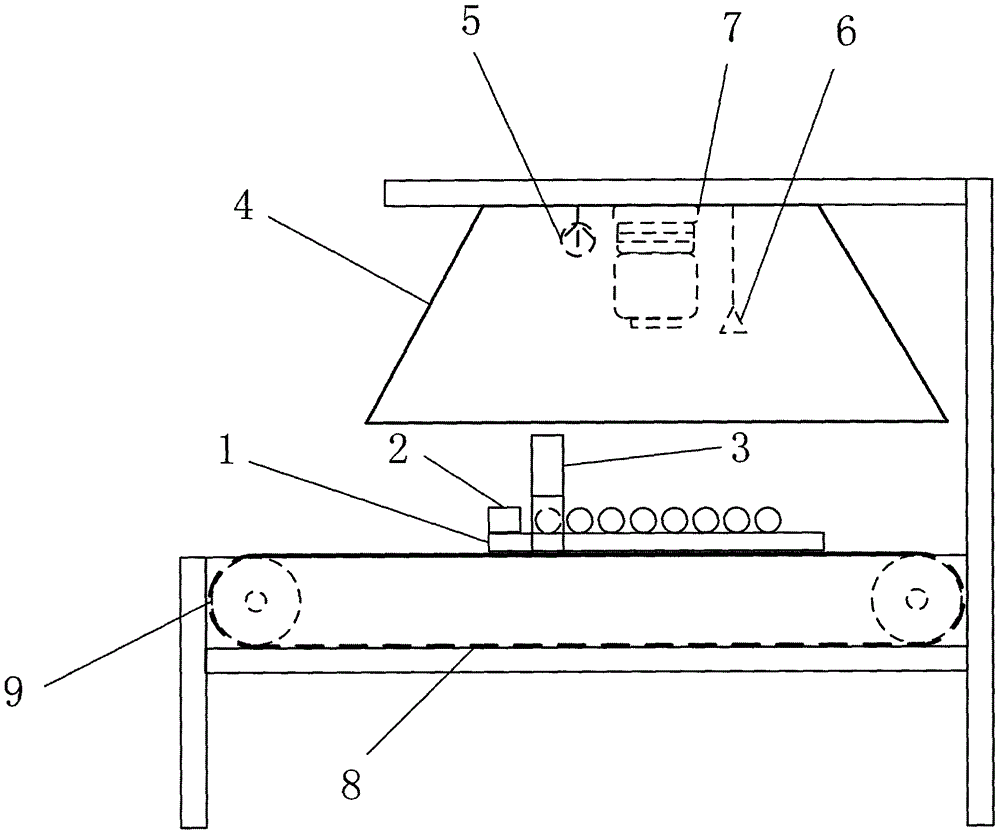

[0018] see figure 1 , a kind of corn grain quality visual detection device of the present invention, comprises conveying material plate 1, shaking source 2, scraper plate 3, light-shielding box 4, photoelectric sensor 5, illuminating light source 6, CCD camera 7 and transmission mechanism, wherein:

[0019] The shaking source 2 is located at the front end of the conveying material plate 1; the scraper 3 is located at the middle end of the conveying material plate 1; the conveying material plate 1 is located above the transmission mechanism; 8 and a drive motor 9 connected to the synchronous belt; the conveying material plate 1, the shaking source 2, the scraper plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com