Sizing structure for heat isolation sliding window sectional bar

A technology of sliding windows and profiles, which is applied in the field of shaping structures of heat-insulating sliding window profiles, which can solve the problems of long air-cooled conveying shaping lines, high energy consumption, and enlarged factory area, so as to increase the area and reduce consumption , the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

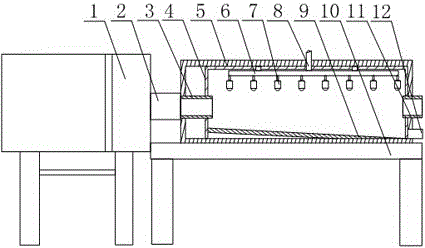

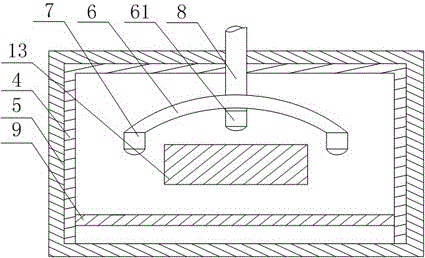

[0021] Such as figure 1 with figure 2 As shown, this embodiment includes a molding machine body 1 and a water-cooled box 5 mounted on a bracket 10. The two ends of the water-cooled box 5 are respectively provided with a coaxial feed pipe 3 and a discharge pipe 11, the molding machine body The discharge barrel 2 of 1 is butted with the feed pipe 3, a heat insulation cavity 4 is installed in the water-cooled box 5, and the feed pipe 3 and the discharge pipe 11 respectively penetrate the two side walls of the heat insulation cavity 4. A downwardly curved arc-shaped branch pipe 6 is provided in the heat insulation cavity 4. The branch pipe 6 covers the area between the feed pipe 3 and the discharge pipe 11. A plurality of sides are respectively installed at the ends of the two bending sections of the branch pipe 6 Nozzle 7, a plurality of main nozzles 61 distributed side by side are arranged in the middle of the lower wall of the branch pipe 6, a water injection pipe 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com