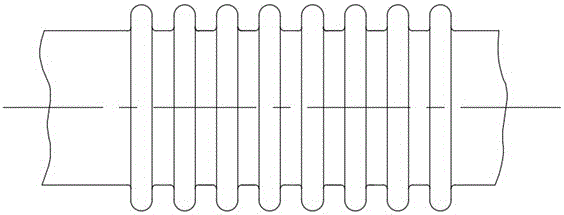

Stainless steel pipe hydraulic wave expansion die and equipment

A stainless steel pipe and hydraulic technology, applied in the field of stainless steel pipe hydraulic expansion molds and equipment, can solve problems such as being unfavorable for large-scale and multi-variety processing, difficult to store due to the large number of molds, and unable to achieve continuous processing, and to reduce labor. Strength, improve the processing qualification rate, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

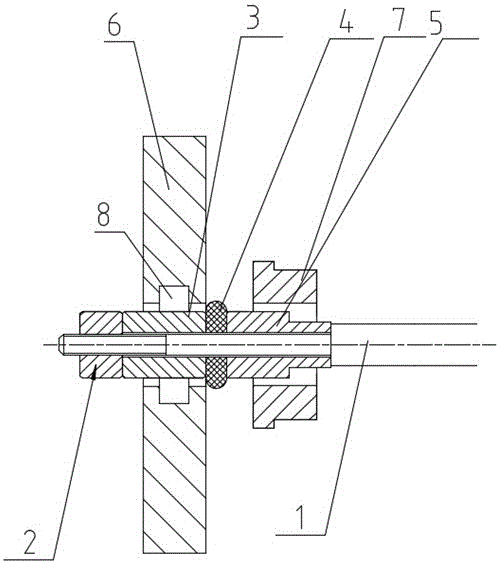

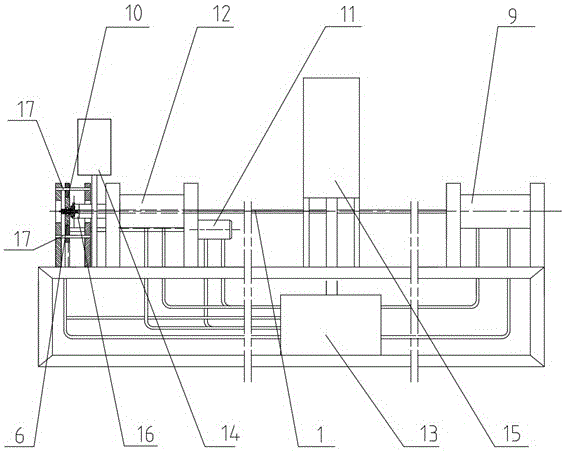

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as figure 2 As shown, the stainless steel pipe hydraulic expansion wave mold includes a connecting rod 1. One end of the connecting rod 1 is a stepped shaft structure. The small diameter end of the connecting rod 1 is sequentially fitted with a lock nut 2, a first The stopper 3, the elastic expansion ball 4 and the second stopper 5, the outer diameter of the large diameter end of the connecting rod 1 is not greater than the outer diameter of the second stopper 5, the first stopper 3, the expansion ball 4 and the second stopper The space between the block 5 and the connecting rod 1 is fit, the lock nut 2 is connected with the connecting rod 1 through threads, the first block 3 is covered with an expansion wave mold 6, and the second block 5 is covered with a push rod sleeve 7. Between the expansion wave mode 6 and the first stopper 3, between the ejector rod sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com