Technological method and device for hot delivery and hot charging of continuous casting billet

A process method and technology of continuous casting slabs, which are applied in the field of metallurgy, can solve problems such as inaccurate elevation, inaccurate elevation, inaccurate hot delivery position, etc., and achieve the effects of high conveying efficiency, simple structure, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

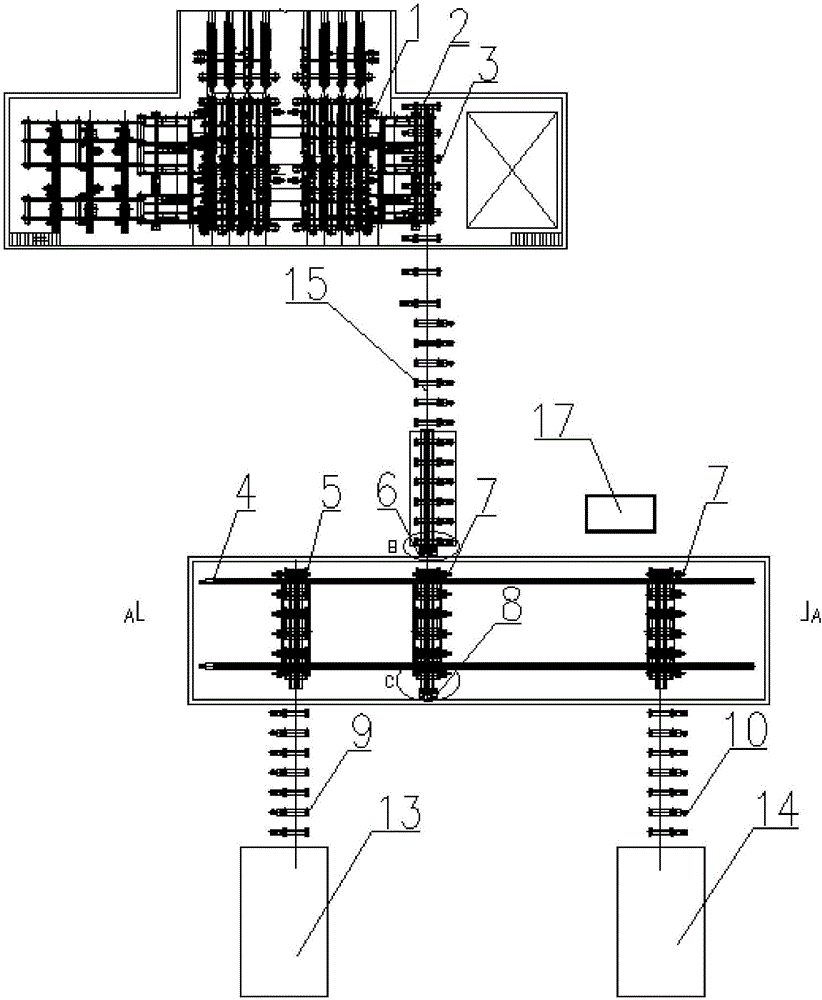

[0023] like Figure 1-5 As shown, a continuous casting slab hot delivery and hot charging process method of the present invention:

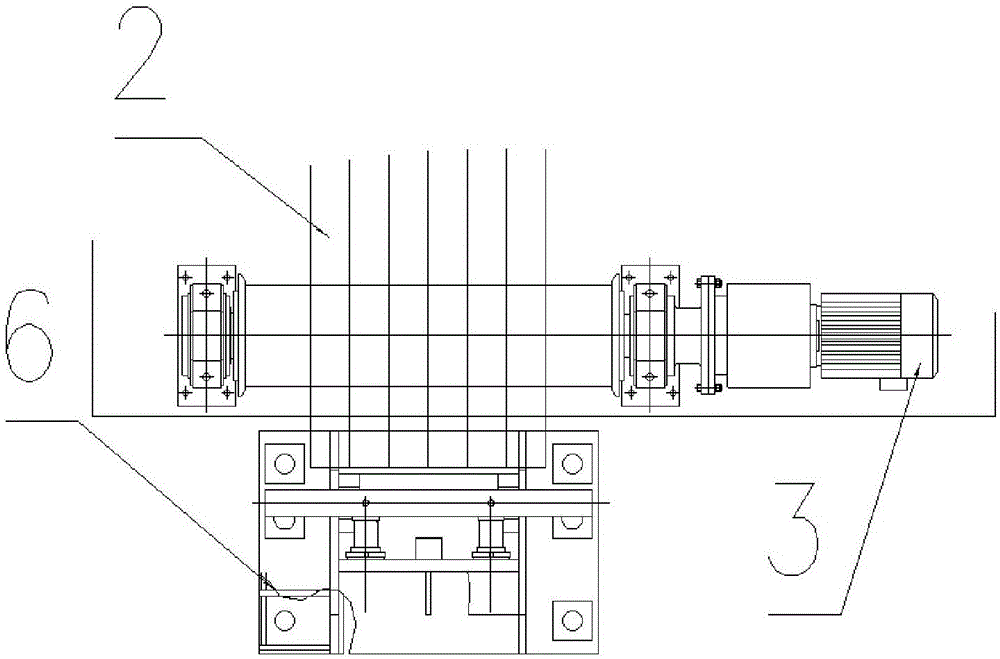

[0024] The continuous casting slab 2 produced by the continuous casting machine 1 is transferred from the output side of the continuous casting machine to the hot delivery roller table 3 for hot delivery. Roller table 3 stops automatically.

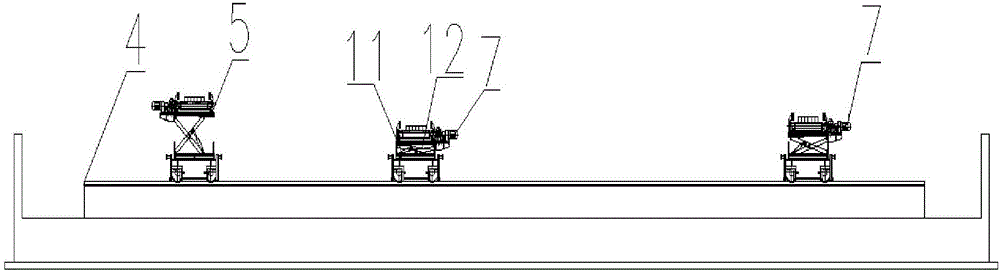

[0025] When the workshop considers the hot feeding heating furnace 13, the roller table traversing trolley 5 stops ahead of time along the track 4 at the lower end of the hot feeding line 15, and the roller table on the roller table traversing trolley 5 starts 5 seconds earlier. The plate 6 descends to the lower limit position, and the multiple continuous casting billets 2 are transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com