Method for making high aspect ratio silver nanowires

A high-aspect-ratio, silver nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as harmful turbidity and transmittance, insufficient conventional methods, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

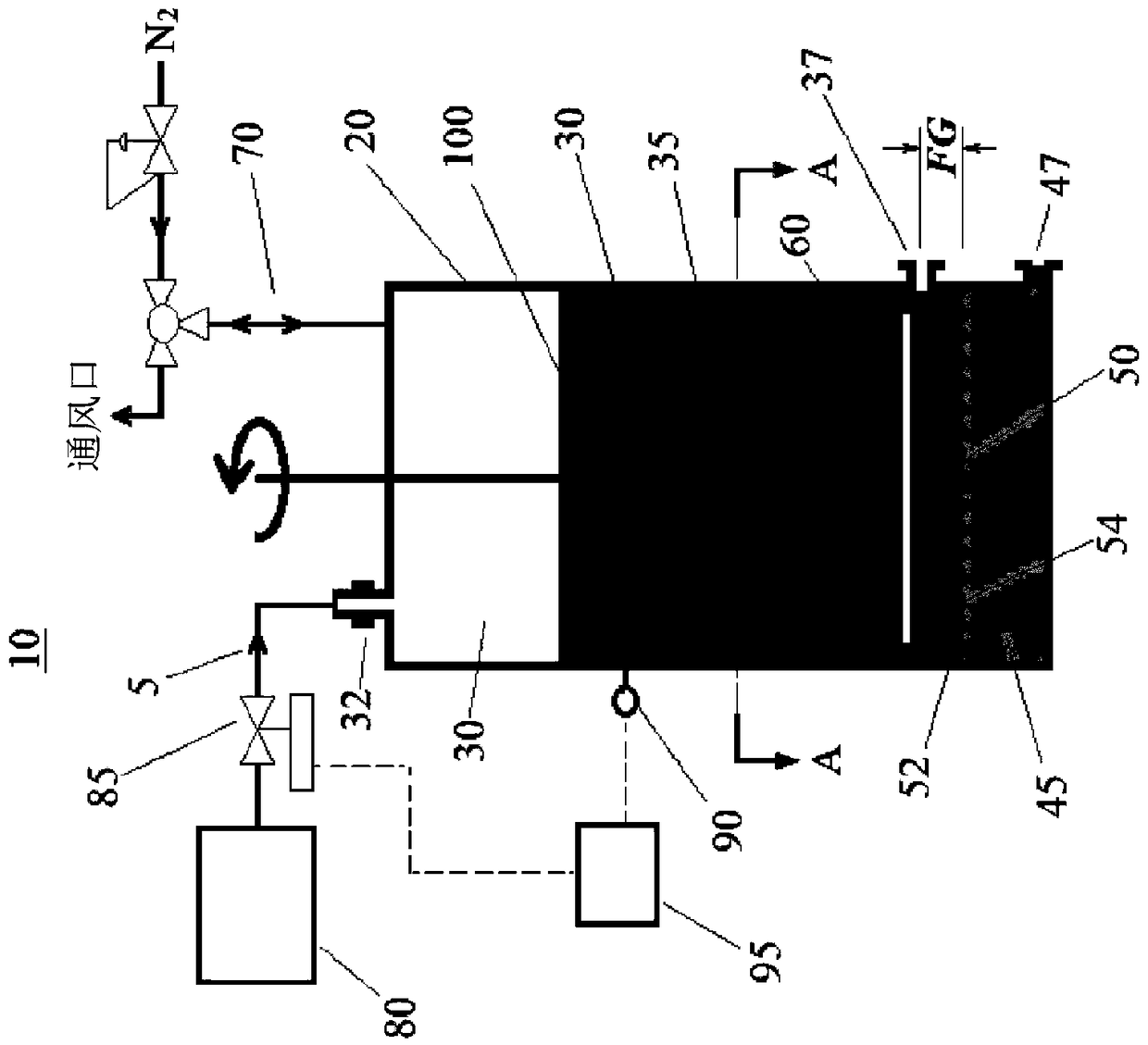

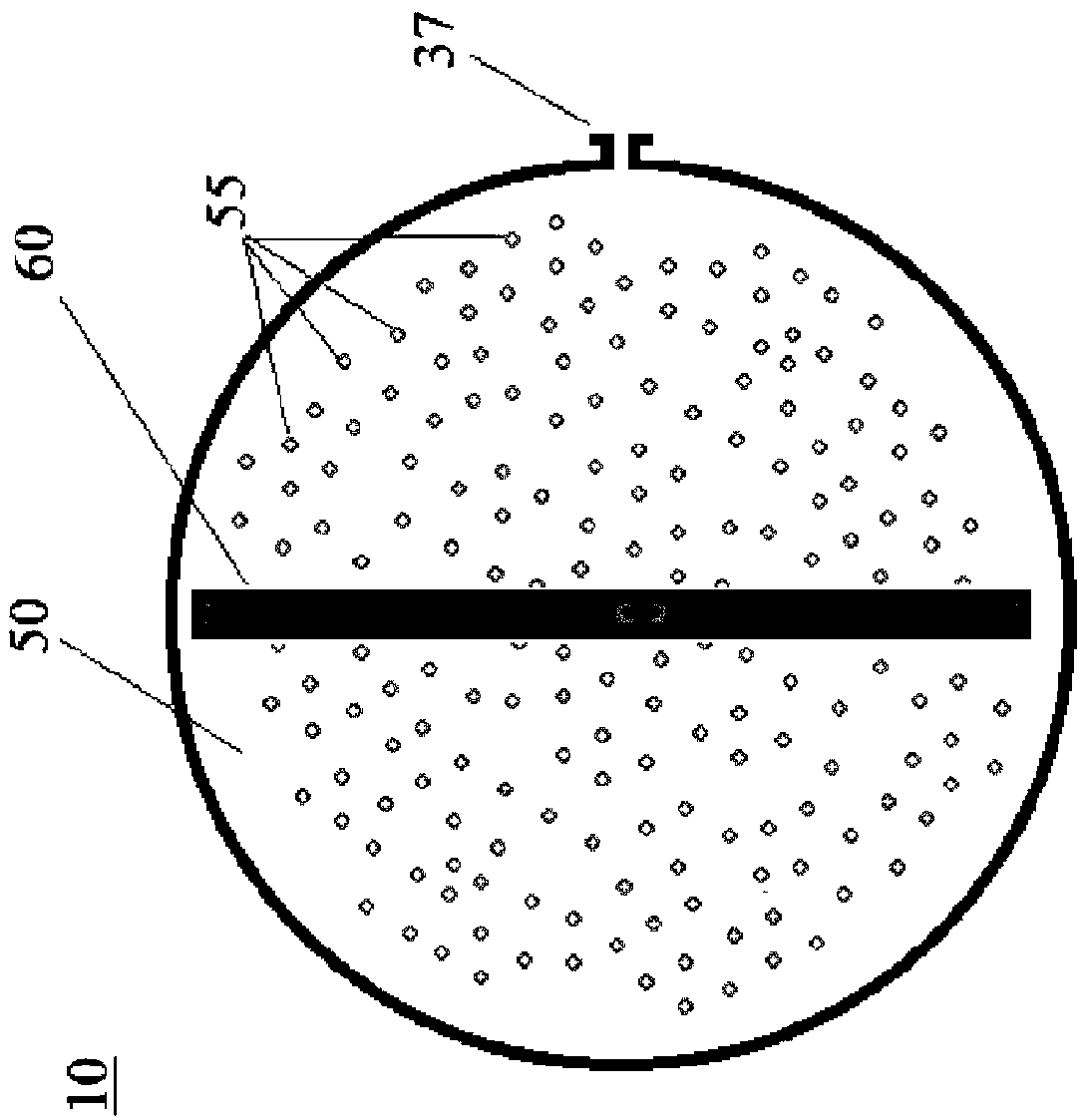

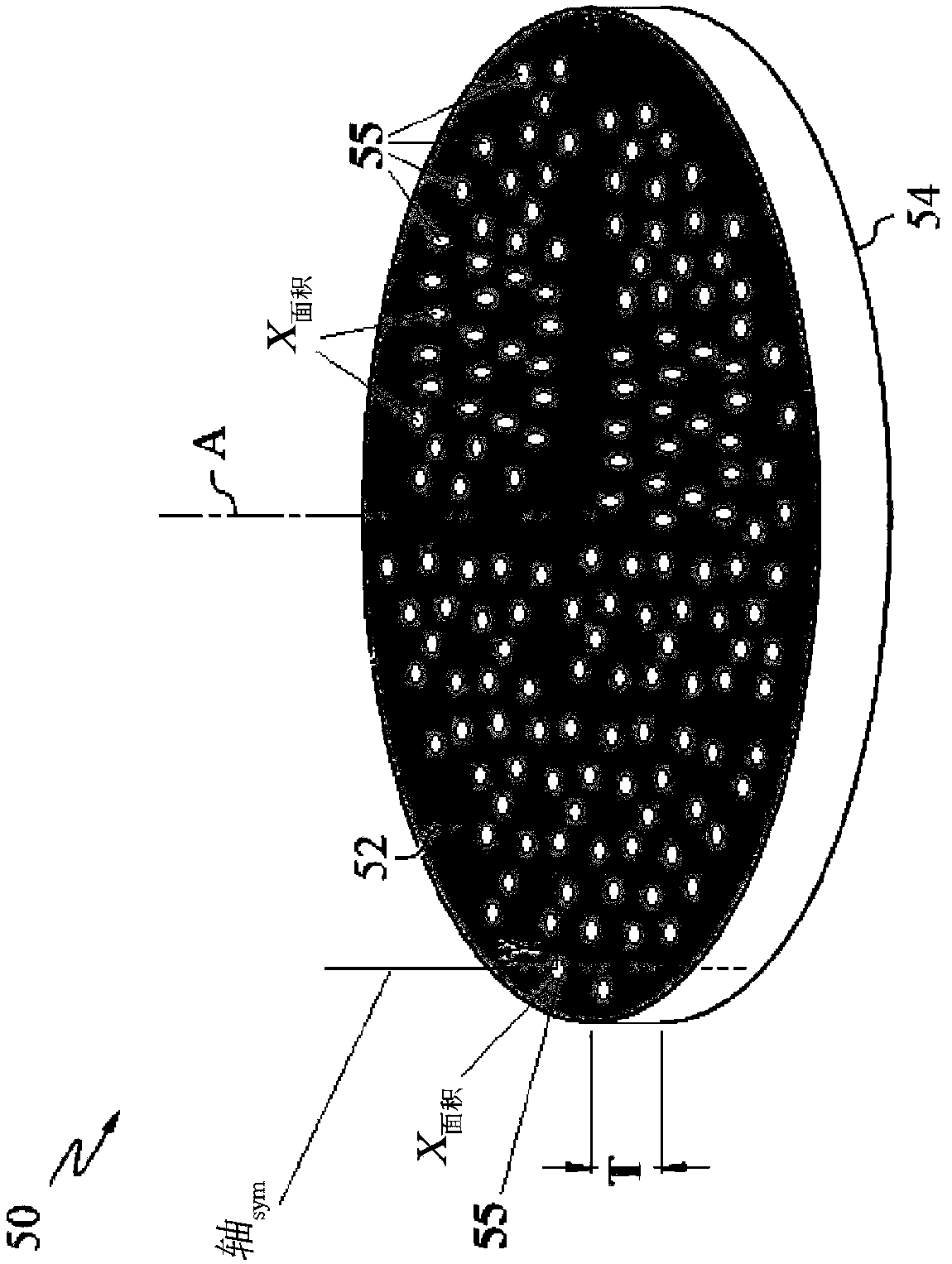

[0065] There is 162cm use accommodation 2 An Advantec / MFS Model UHP 150 Stirred Cell Filter with a filtration area of 100000000000000000000000000001 and equipped with a magnetic cylindrical rod impeller filtered an aqueous feed solution containing silver solids including both high aspect ratio silver nanowires and low aspect ratio silver particles. The filter housing was placed on a Mettler model SB32001DR balance / magnetic stirring apparatus. The porous media used was a 5 μm hydrophilic polycarbonate track etched (PCTE) filter membrane supported in the bottom of the filter housing. Nitrogen pressure is used to power to create a pressure drop across the porous media. Nitrogen is supplied to the headspace in the filter housing. The pressure in the headspace was measured using a Cole-Parmer model 68075-16 pressure transducer. Nitrogen gas fed into the filter housing passes through a three-way ball valve mounted on top of the filter housing. The three-way valve effected the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com