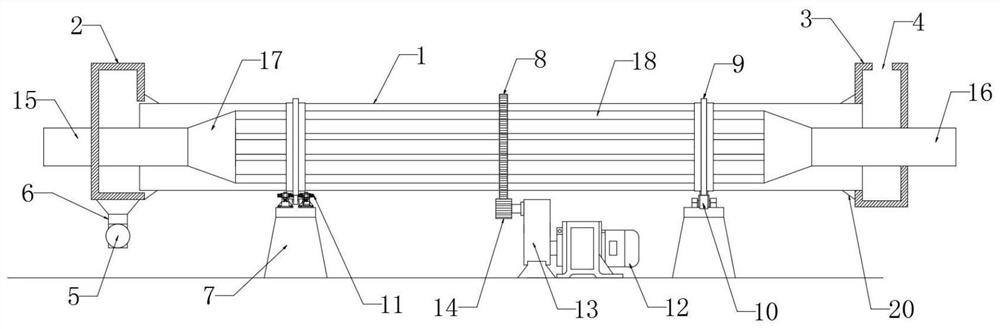

Built-in multi-tube indirect heating rotary carbonization furnace with high heat exchange area

A technology of rotary carbonization furnace and heat transfer area, applied in the direction of rotary carbonization furnace, etc., can solve the problems of low thermal efficiency, small output, slow heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

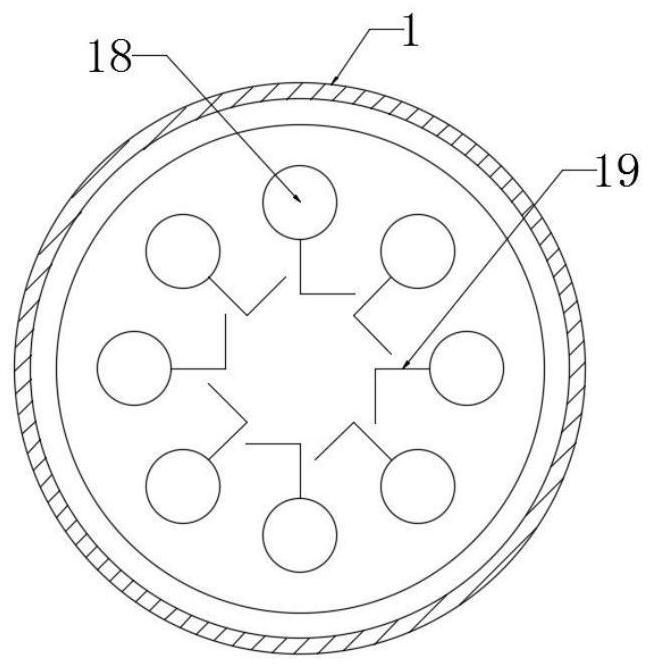

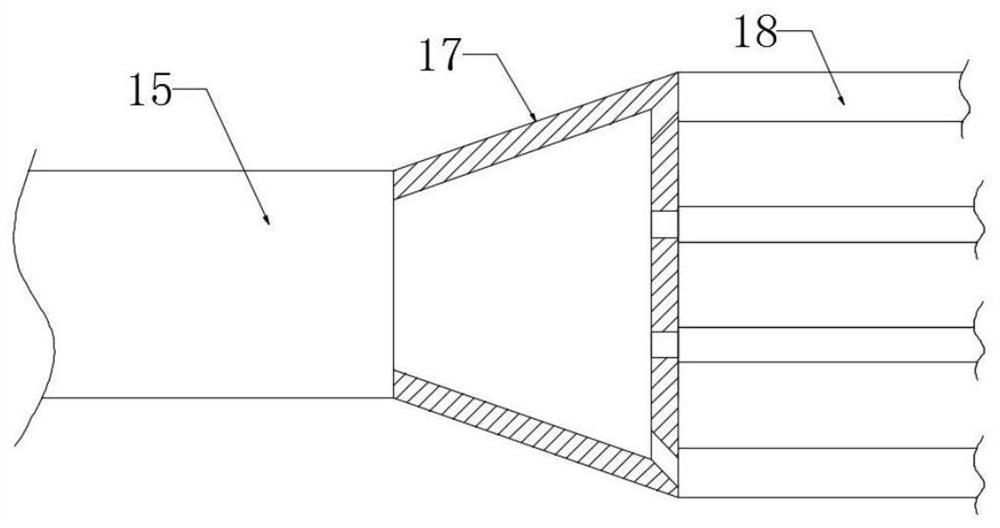

[0024] Embodiment: When the device is in use, the motor 12 is first started, and the output shaft of the motor 12 drives the drive gear 14 to rotate through the reducer 13. Since the drive gear 14 meshes with the ring gear 8, the ring gear 8 rotates with the drive gear 14 And drive the cylinder body 1 to rotate, then pass the hot air into the inside of the air inlet pipe 15 through the heating device, so that the hot air passes into the inside of the hot air pipe 18 through the connector 17, thereby heating the inside of the cylinder body 1, so that the cylinder body The inside of the body 1 reaches a high temperature state, and then the material to be carbonized is added to the inside of the cylinder 1 through the material inlet 4, so that the material rotates inside the cylinder 1 and is heated to be carbonized at the same time; The outer surface is provided with evenly distributed lifting plates 19, so that when the material is tumbling inside the cylinder 1, the material ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com