A support device for eccentric thin-walled cylinder

A technology of supporting device and thin-walled cylinder, applied in the field of mechanical processing, can solve problems such as difficult to effectively support, poor surface quality, difficult supporting, etc., to achieve the effect of improving processing efficiency, meeting surface quality requirements, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

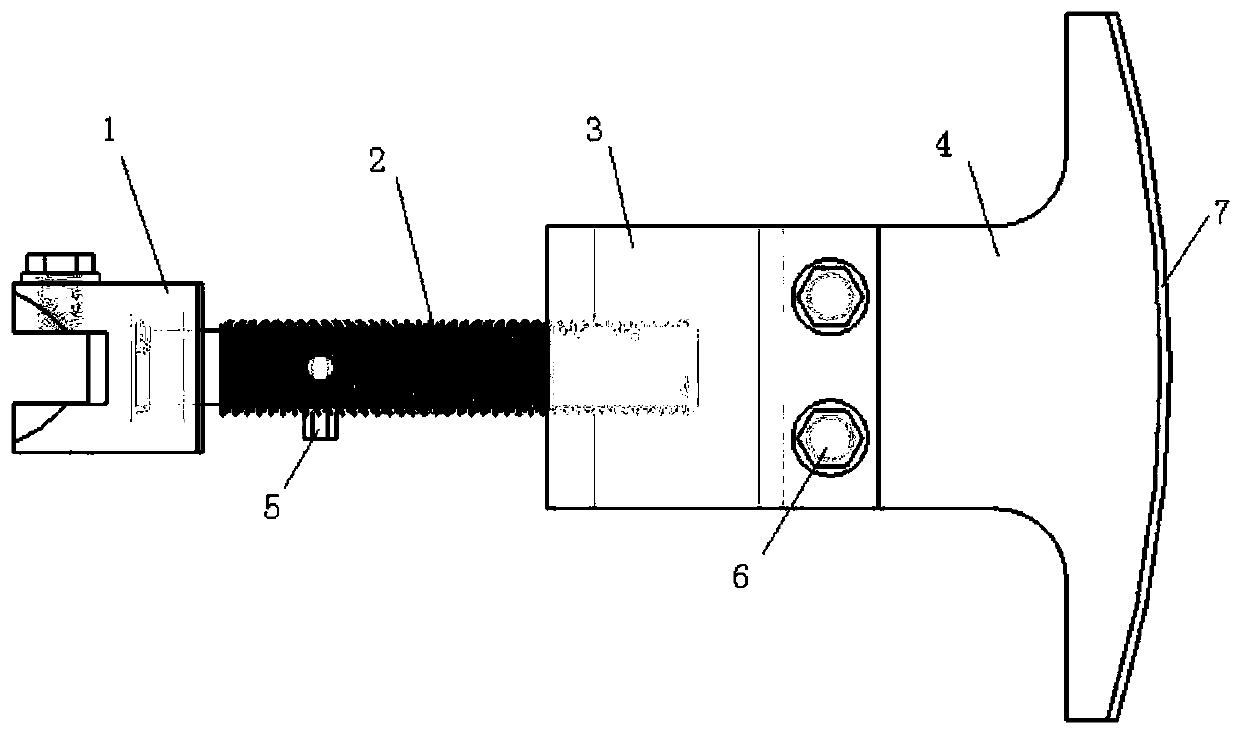

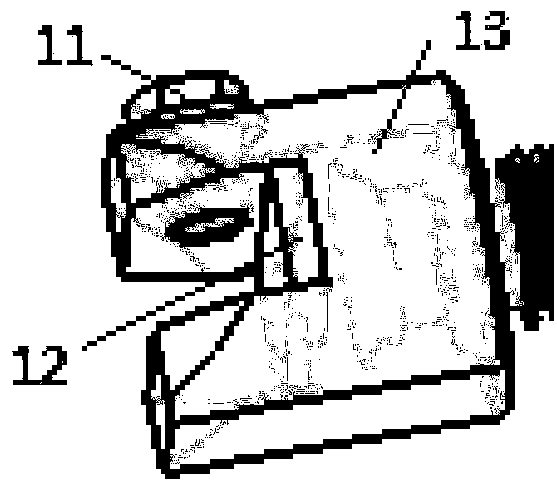

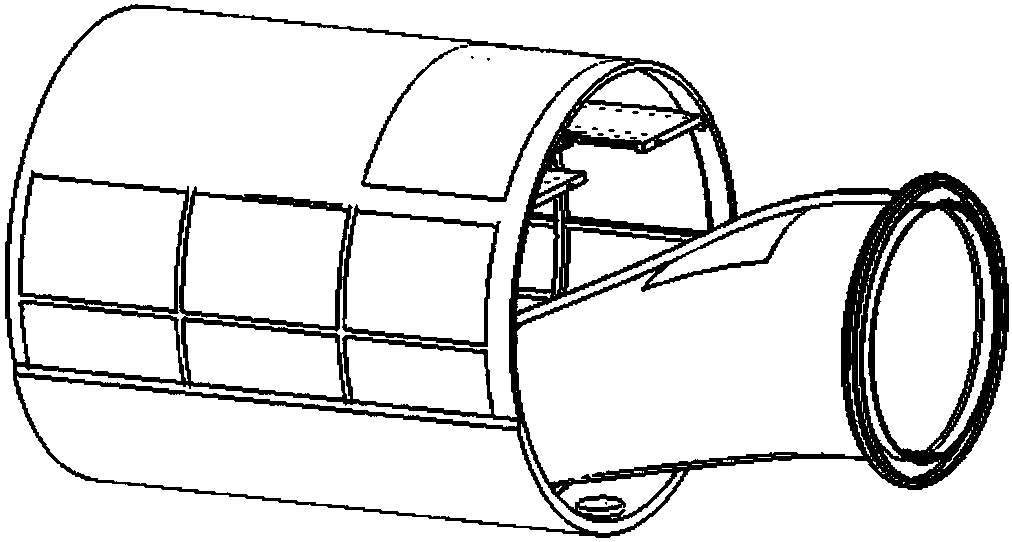

[0034] The basic idea of the present invention is: the present invention is a support device for a large eccentric thin-walled cylinder. pad. One end of the telescopic screw rod is threadedly connected to the internal thread of the base, and the length of the entire supporting device can be adjusted by turning the rotating handle; the other end is adjustable connected to the universal joint body to form an angle-adjustable automatic Adaptive joint; the support block is fixed on the base through locking screws, and rubber pads are pasted on the support block and the adaptive joint respectively. Its structural design is reasonable, easy to use, and the support block can be replaced according to eccentric parts of different sizes and shapes, which solves the difficulty of supporting and stressing the eccentric thin-walled cylinder due to the eccentric structure during the turning and milling process. Uneven, rough surface processing problems.

[0035] The present invention wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com