A spiral pipe inner wall grinding and polishing robot adaptable to different pipe diameters

A spiral technology that adapts to different types and is applied in grinding/polishing equipment, grinding/polishing safety devices, grinding racks, etc. It can solve problems such as excessive volume and unfavorable mechanism turning, so as to improve work efficiency and save energy. Cost, the effect of avoiding the phenomenon of knife punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

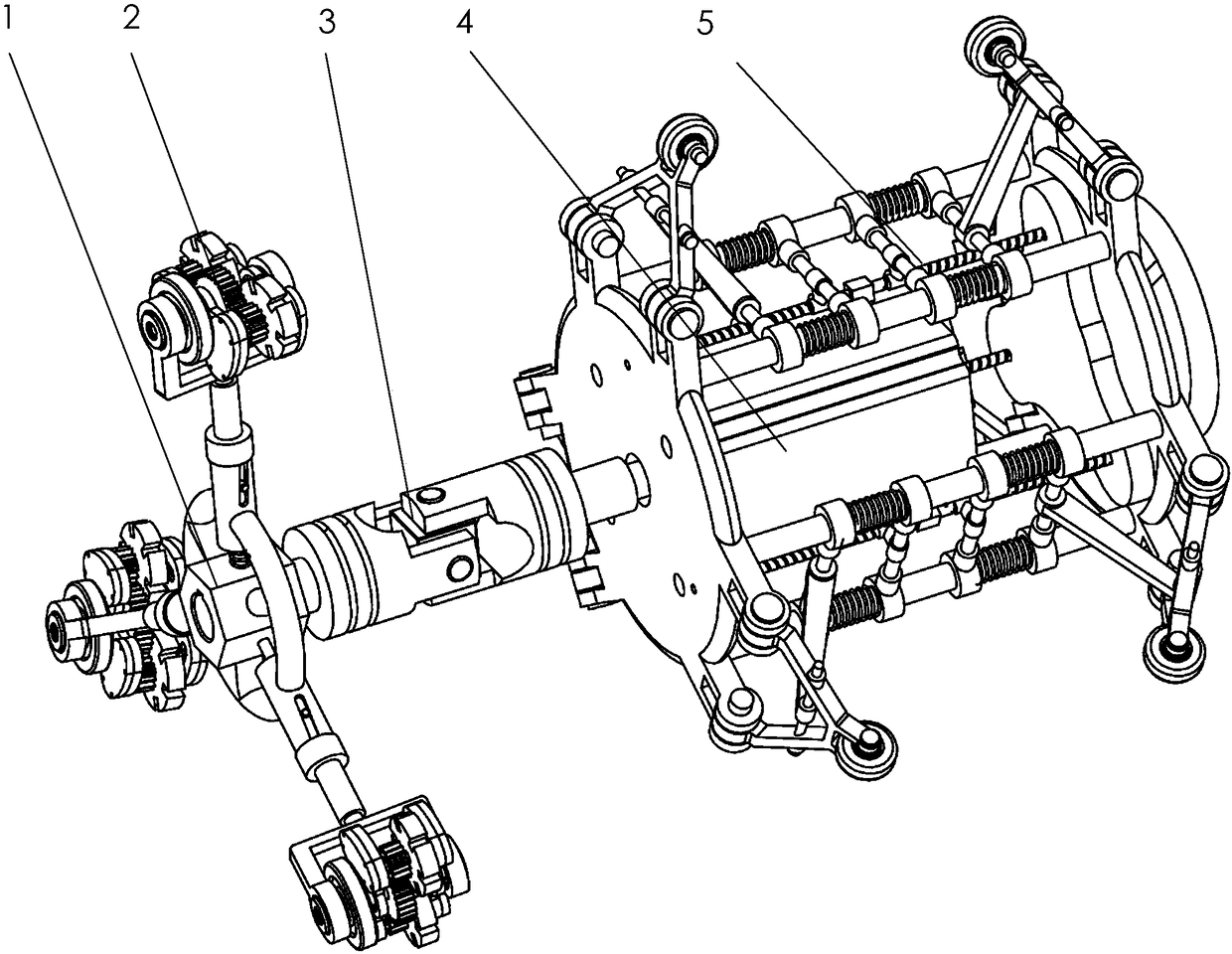

[0026] The present invention is a spiral pipe inner wall grinding and polishing robot that can adapt to different pipe diameters, including a hub assembly 1, a driving wheel grinding assembly 2, a cross shaft universal joint 3, a motor and its power and control assembly 4, and a direction maintaining mechanism 5. Grinding and polishing of tiny pipes can be realized. The hub assembly 1 and the cross shaft universal joint 3 are splined and installed, and the driving wheel grinding assembly 2 has three sets in total, and the two ends of the driving shaft 208 pass through the bearing and the hub The drive shaft bracket 102 in the assembly 1 is installed in cooperation, the motor and its control and power assembly 4 are installed on the direction maintaining mechanism 5, and the motor shaft and the cross shaft universal joint 3 are installed with splines. Such as figure 1 shown.

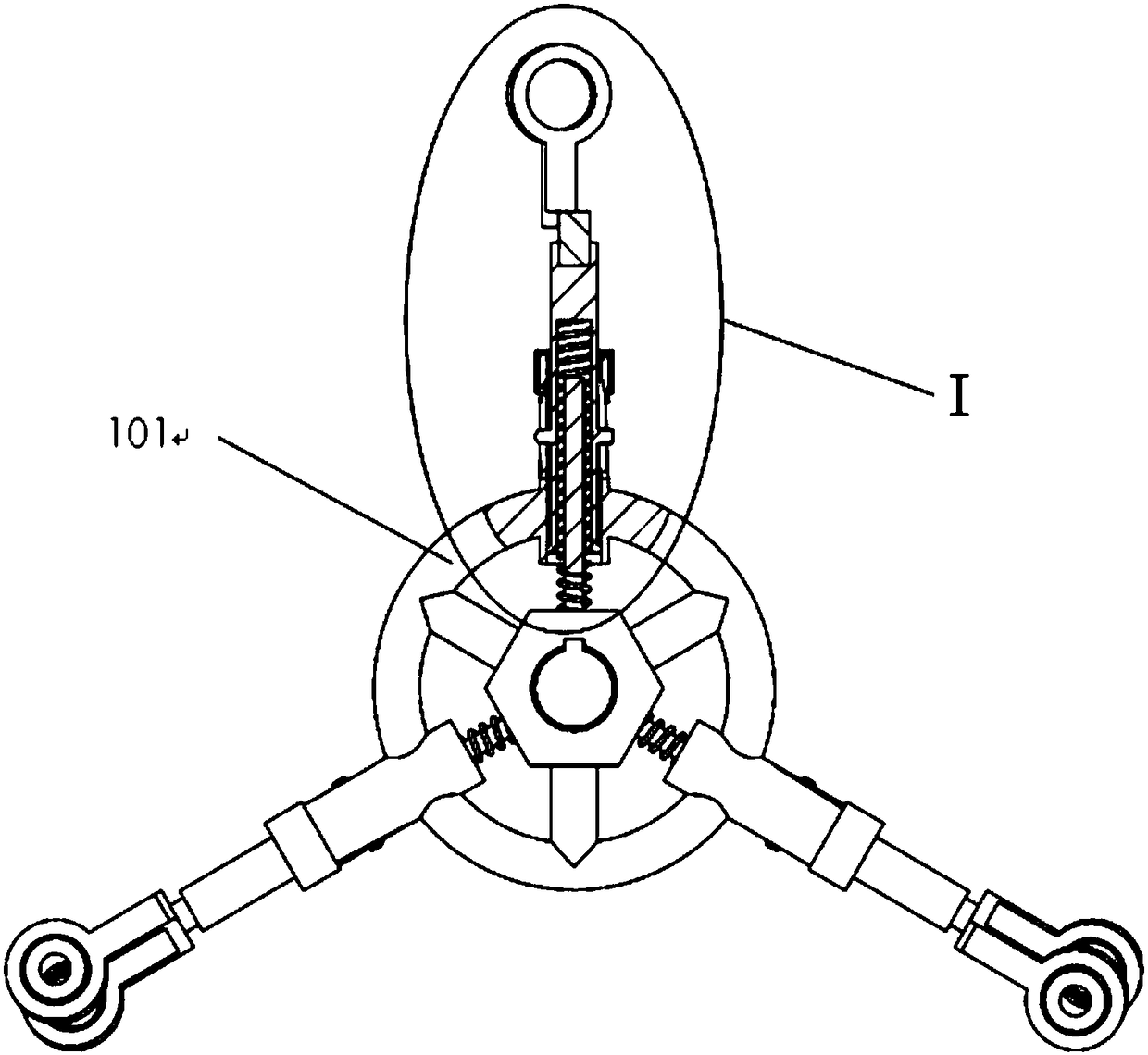

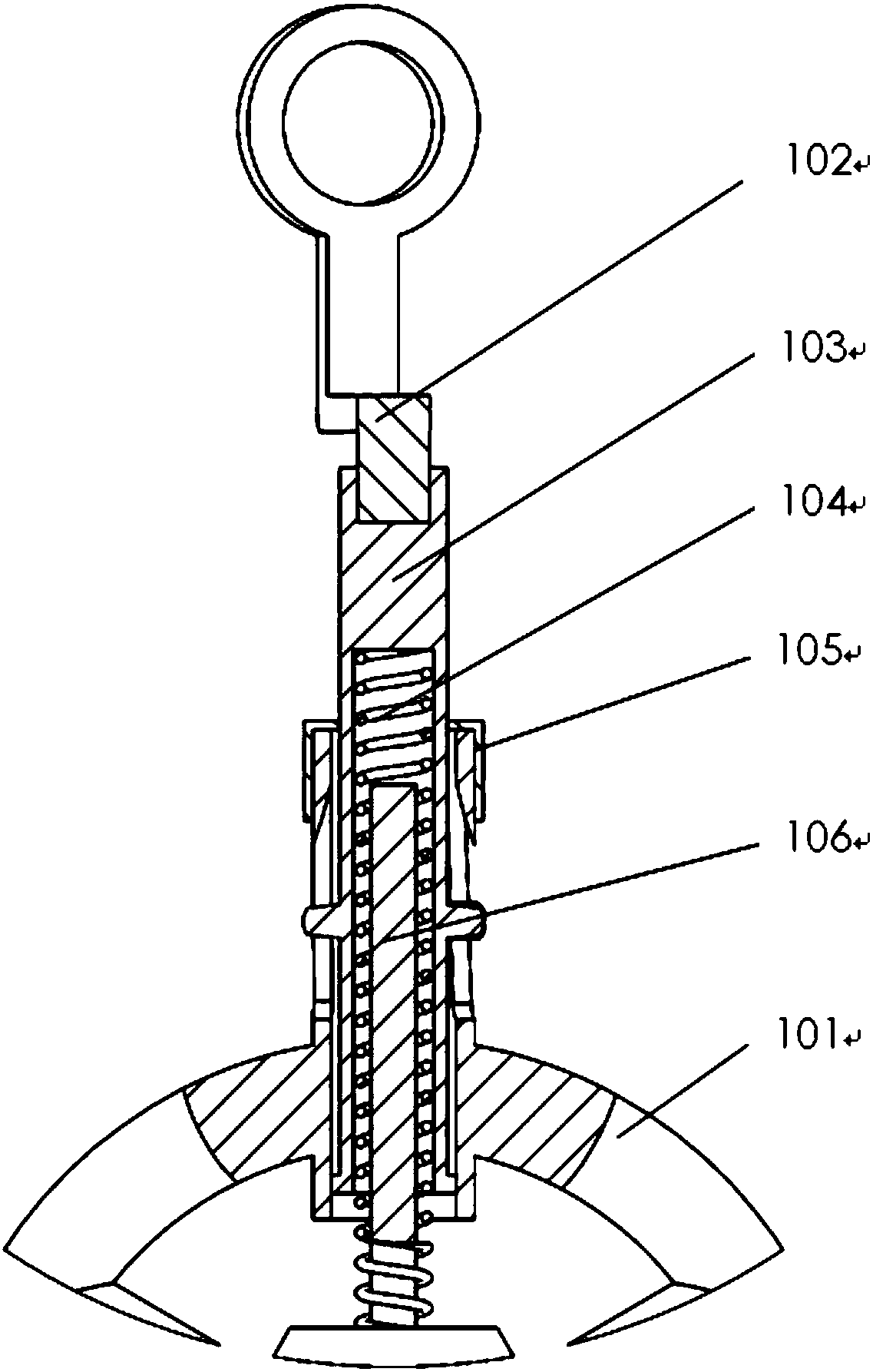

[0027] The wheel hub assembly 1 of the present invention is composed of a wheel hub 101, a drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com