Height-adjustable outboard motor hanging rack

A high-level technology for outboard motors, applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as waste of resources, damage to propellers, rising of outboard motors, etc., and achieve the effects of convenient storage, reliable connection, and flexible disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

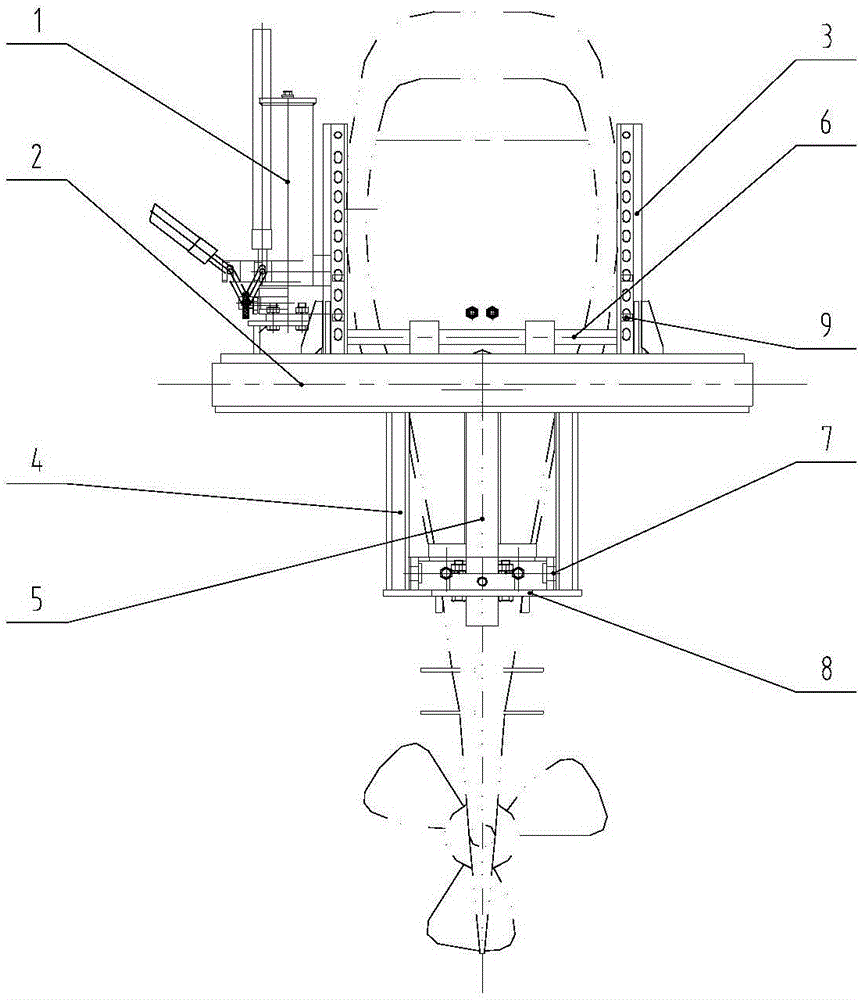

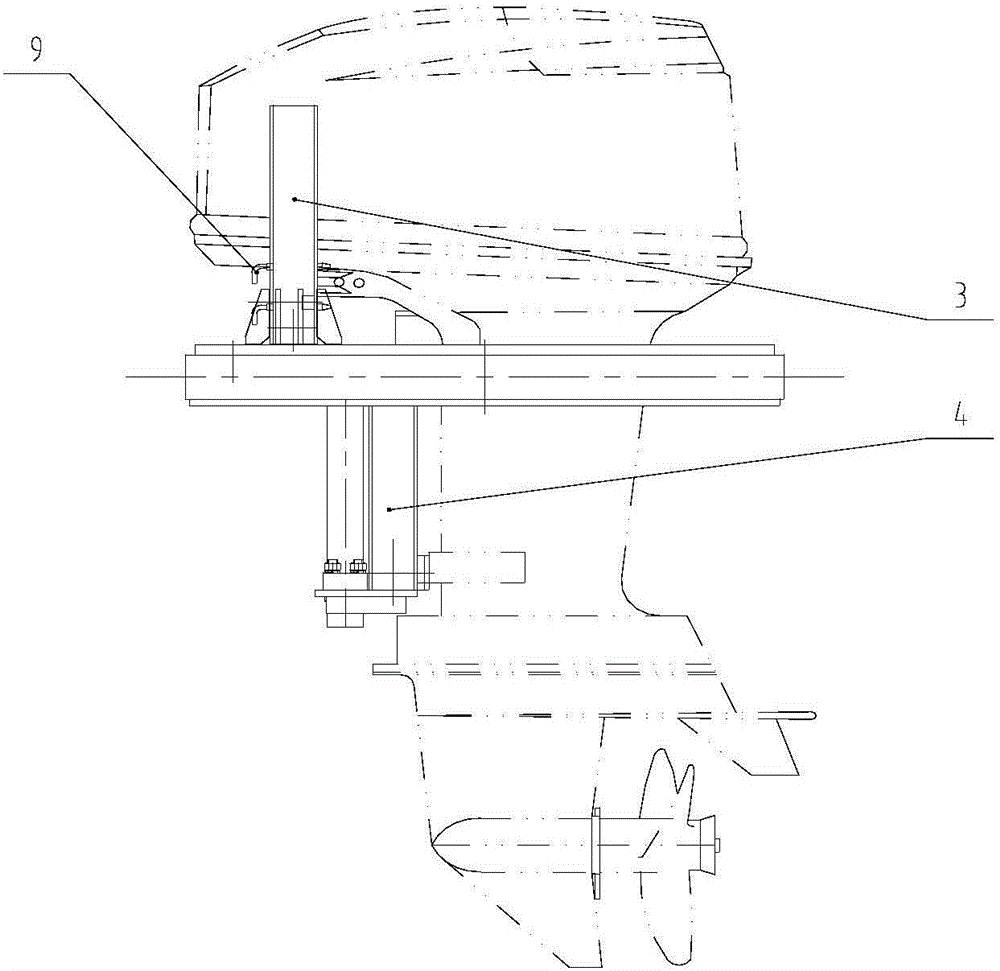

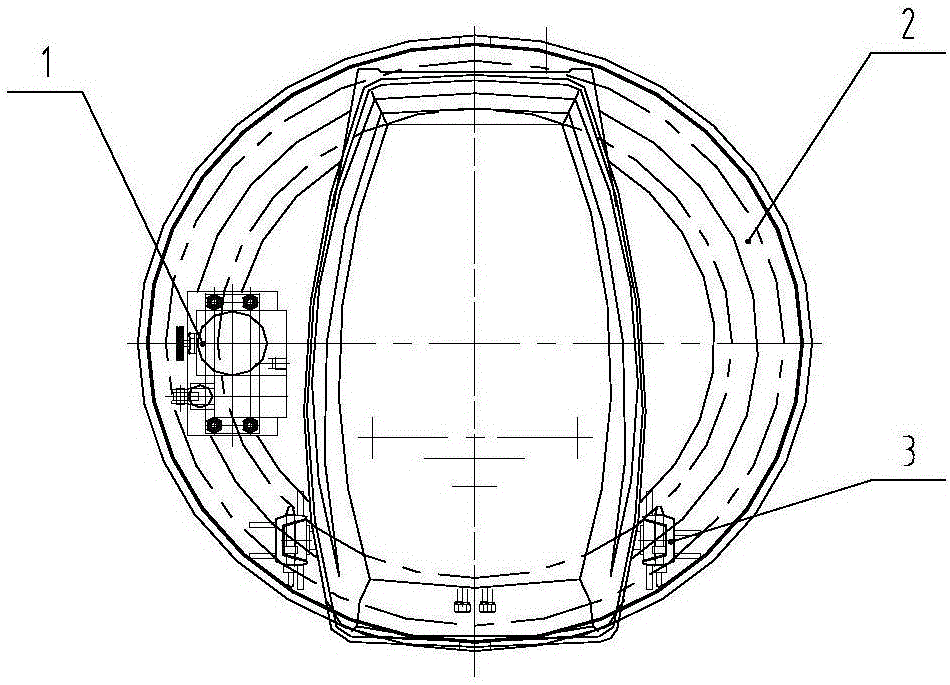

[0020] See attached Figure 1-4 , a height-adjustable outboard motor hanger, which includes: hand pump 1, platform 2, upper guide rail 3, lower guide rail 4, oil cylinder 5 driven by hand pump 1, upper roller assembly 6, lower roller assembly Assembly 7, oil cylinder mount 8;

[0021] The center of the platform 2 accommodates the outboard motor. The hand pump 1 used to drive the piston rod 10 of the oil cylinder 5 to reciprocate is installed on one side of the outboard motor on the upper part of the platform 2. The section of the upper guide rail 3 is a groove structure, which is welded vertically and symmetrically. On both sides of the outboard motor on the upper part of the platform 2; the section of the lower guide rail 4 is a groove structure, welded on both sides of the outboard motor on the lower part of the platform 2 and parallel to the upper guide rail 3, and the oil cylinder mounting seat 8 is welded on the bottom of the lower guide rail 4, and The lower guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com