Fully-automatic filling and seaming packaging system

A fully automatic, sewing package technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of pollution, inability to meet the requirements of automation, waste of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

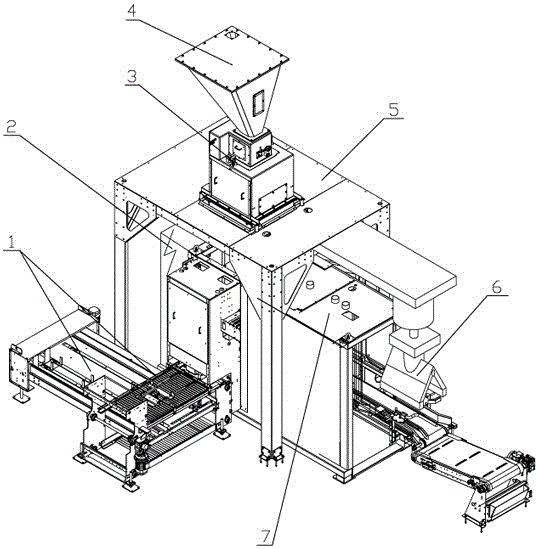

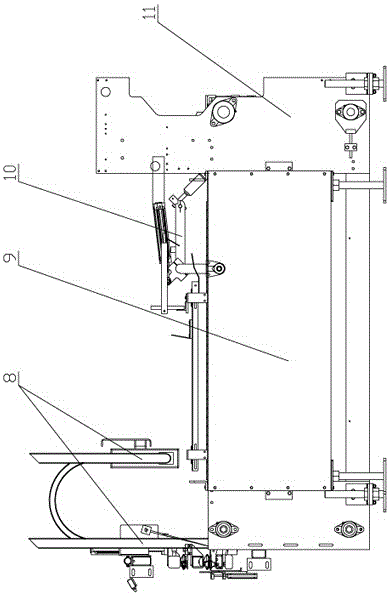

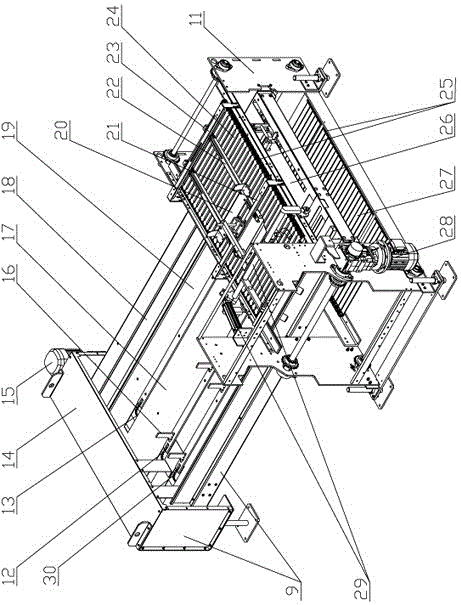

[0045] see Figure 1-Figure 21 , the present invention is a fully automatic sewing bag system, which has a steel structure support platform 5, the front part of the steel structure support platform is provided with an automatic conveying bag-dividing bag rubbing device 1, and the steel structure support platform is equipped with a multi-functional clamping bag filling device. The multi-functional bag filling device is connected with the automatic conveying bag-dividing and rubbing device, and the corresponding position above the multi-functional bag filling device is provided with a directional suspension double-sensing automatic quantitative packaging scale 3, and a directional suspension double sensor The upper part of the sensing automatic quantitative packaging scale is connected with a feeding hopper 4; one side of the multi-functional bag filling device is connected with a sewing bag conveying assembly 7, and the sewing bag conveying assembly is connected with a packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com