Double-layer paper packaging machine

A paper bag, double-layer technology, applied in the field of pallet stacking equipment, can solve the problems of affecting packaging quality, looseness, offset, poor safety, etc., and achieve the effects of compact structure, beautiful packaging and high equipment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

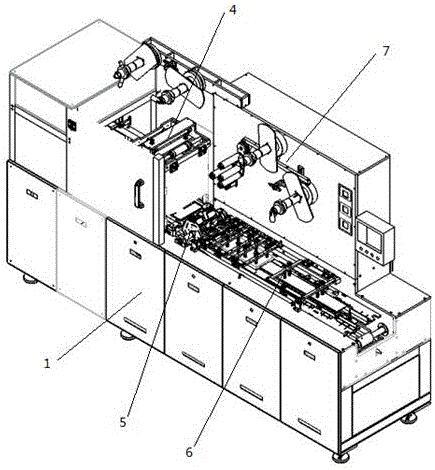

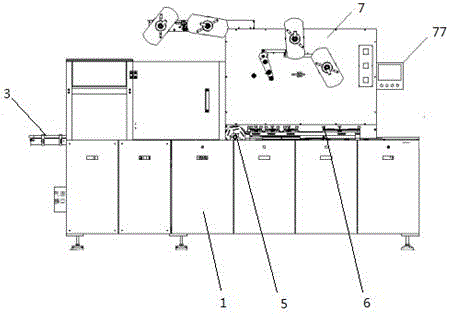

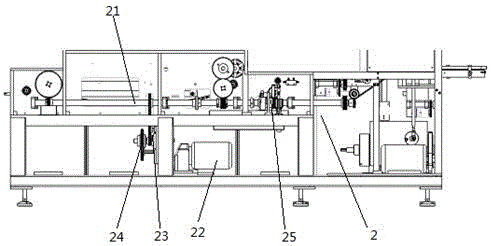

[0029] Such as Figure 1-3 A double-layer paper packaging machine shown includes a frame 1 and a main transmission mechanism 2 fixedly installed inside the frame 1. The main transmission mechanism 2 includes a main drive rod 21 and a main transmission motor 22. The drive of the main transmission motor 22 The shaft is fixedly provided with a transmission sprocket 23, the transmission sprocket 23 is movably connected with the gear on the main drive rod 21 through a chain, and an overload protector 24 is fixedly installed on the drive shaft of the main drive motor 22, and the main drive rod 21 moves from left to right It is movably connected with the feeding conveying mechanism 3, the film lowering mechanism 4, the turntable mechanism 5 and the heat-sealing forming mechanism 6 in turn, and the film roll fixing mechanism 7 is fixedly installed on the rear side of the turntable mechanism 5 and the heat-sealing forming mechanism 6, and the main driving rod 21 The clutch 25 is also f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com