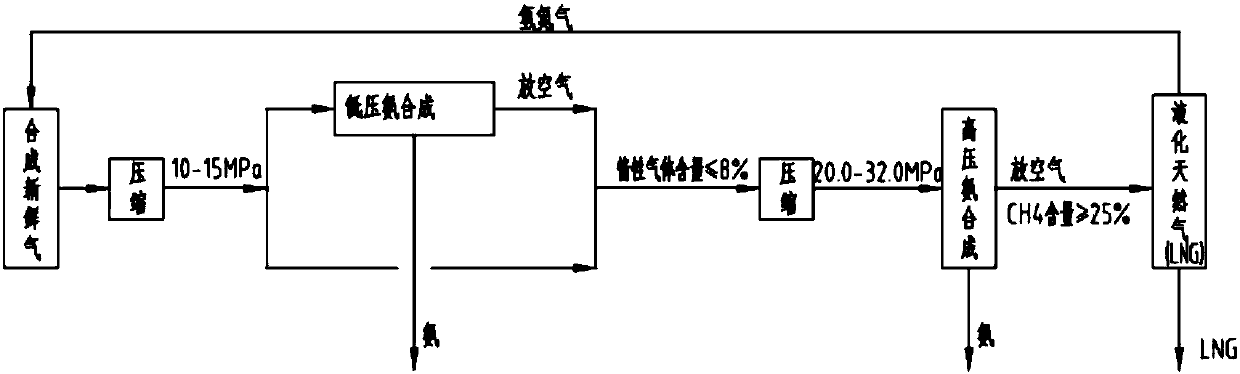

Non-isobaric ammonia synthesis and co-production of liquefied natural gas (lng) process

A technology for liquefied natural gas and ammonia synthesis, applied in the field of synthetic ammonia, can solve problems such as unfavorable large-scale development of ammonia synthesis units, high requirements for equipment and materials, and a large amount of catalysts used, so as to achieve strong market risks, reduce emissions and environmental pollution, and resist the market. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] After compressing the synthetic fresh gas to 14MPa, it is divided into two paths, and one path is passed into the φ2600mm low-pressure ammonia synthesis tower. The temperature of entering the tower is controlled at 180~230℃, the content of inert gas is about 10%, and the hot spot temperature of the synthesis tower is controlled at 360~400℃ to synthesize ammonia. , release CH in the air 4 The content is controlled at about 18%; the low-pressure ammonia synthesis vent air and another synthetic fresh gas are pressurized to 28.5MPa, and fed into the φ1200mm high-pressure ammonia synthesis tower. Synthesize ammonia under high pressure; release CH in the air for high pressure ammonia synthesis 4 The content is about 28%, which is removed and recovered to produce liquefied natural gas (LNG), and the rest of hydrogen and nitrogen is returned to the system as fresh gas for ammonia synthesis.

Embodiment 2

[0054] After compressing the synthetic fresh gas to 13.5MPa, it is divided into three routes, and the first route and the second route are respectively fed into the φ1800mm low-pressure ammonia synthesis tower. To synthesize ammonia, the content of inert gas in the two-way venting air is controlled at about 10%, the two-way venting air and the third-line synthetic fresh gas are pressurized to 28.5MPa, and fed into a φ1200mm high-pressure ammonia synthesis tower, and the temperature entering the tower is controlled at 180~ 230 ° C, the content of inert gas is about 22%, and ammonia is synthesized under high pressure. High Pressure Ammonia Synthesis Releases CH in Air 4 The content is about 27%, which is removed and recovered to produce liquefied natural gas (LNG), and the rest of hydrogen and nitrogen is returned to the system as fresh gas for ammonia synthesis.

Embodiment 3

[0056] After compressing the synthetic fresh gas to 13.5MPa, it is divided into three routes, and the first route and the second route are respectively fed into the φ1800mm low-pressure ammonia synthesis tower. , the content of inert gas in the two-way venting air is controlled at about 15%, the two-way venting air and the third-way synthetic fresh gas are pressurized to 20.0MPa, and the inlet is φ1600mm. The content is about 20%, and ammonia is synthesized under high pressure. High Pressure Ammonia Synthesis Releases CH in Air 4 The content is about 26%, which is removed and recovered to produce liquefied natural gas (LNG), and the rest of hydrogen and nitrogen is returned to the system as fresh gas for ammonia synthesis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com