Method for recovering highly pure manganese dioxide from waste manganese dry batteries, and use of highly pure manganese dioxide

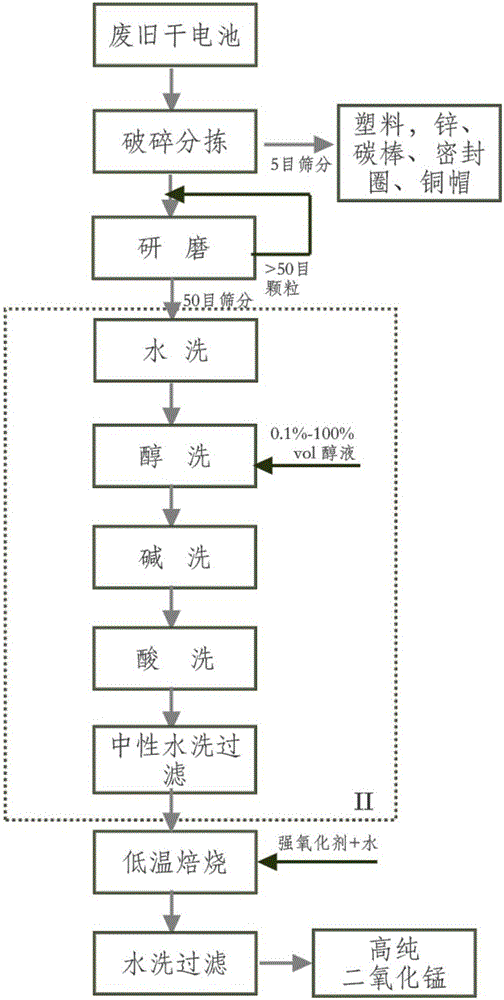

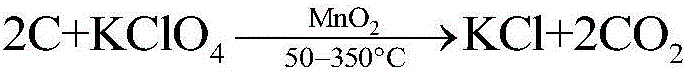

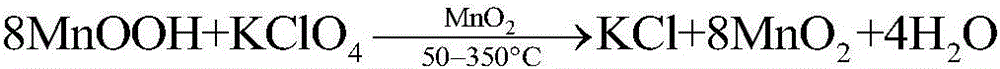

A manganese dioxide and manganese dry battery technology, applied in chemical instruments and methods, manganese oxide/manganese hydroxide, oxidized water/sewage treatment, etc. The problem of high temperature can achieve the effect of low roasting temperature, fast degradation speed, and improved product purity and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take "Huatai brand" zinc-manganese waste dry batteries, crush them with a bite mill, and sieve them through 5-mesh and 50-mesh vibrating sieves to remove the plastic skin, zinc skin, carbon rods, plastic caps, sealing rings, copper caps, etc. Wash the remaining black powder twice with water, twice with absolute ethanol, and filter; then add 50 mL of 0.5mol / L sodium hydroxide, stir at room temperature for 30 minutes, raise the temperature to 70°C, stir and rinse for 10 minutes, remove grease and wax, and Filter out the filter residue; add 50 mL of 0.5 mol / L sulfuric acid, rinse with water for 30 min at room temperature, and wash with water until the washing liquid is neutral, then filter out the sample. Take a certain amount of black powder and mix it with the oxidizing additive KMnO 4 , at 500°C, after constant temperature airtight roasting for 1.0h, take out the black manganese dioxide powder, wash it with water until the conductivity remains unchanged, and measure the...

Embodiment 2

[0032] Get the "Nanfu brand" alkaline manganese waste dry battery, pulverize it with a bite mill, carry out the sieving and water washing steps of Example 1 respectively, wash the black powder obtained twice with 30vol% ethanol aqueous solution, and filter; then go through step 1 Alkali washing, acid washing steps, filter out black samples. Take a certain amount of black powder and mix it with oxidizing additive KClO 4 , at 320°C, after constant temperature airtight roasting for 1.0h, take out the black manganese dioxide powder, wash it with water until the conductivity remains unchanged, and measure the purity of manganese dioxide by sodium oxalate-potassium permanganate back titration method to reach 94.21wt%, which is The recovery rate reached 78.61%. Use an appropriate amount of this manganese dioxide to degrade 200 mg L at room temperature -1 After 150mL of phenol wastewater was degraded for 2.0h, the chemical oxygen demand (COD) of the wastewater was determined to be 4...

Embodiment 3

[0034] Take "Philip brand" alkaline waste dry batteries, crush them with a bite mill, and filter out the black samples through the steps of screening, water washing, alcohol washing, alkali washing, and pickling in Example 2 respectively. Take a certain amount of black powder and mix it with the oxidizing additive KMnO 4 , at 500°C, after constant temperature airtight roasting for 1.0h, take out the black manganese dioxide powder, wash with water until the conductivity remains unchanged, and measure the purity of manganese dioxide by sodium oxalate-potassium permanganate back titration to reach 92.35wt%. The recovery rate reached 55.23%. Appropriate amount of this manganese dioxide is used to degrade 100m g L at room temperature -1 After 200mL of phenol wastewater was degraded for 1.0h, the chemical oxygen demand (COD) of the wastewater was determined to be 236.8mg·L -1 down to 33.5mg·L -1 , reaching the national discharge standard for industrial wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap