Improved enhanced phosphorus removal device and phosphorus removal process

An improved and technological technology, applied in the field of improved enhanced phosphorus removal device and phosphorus removal process, can solve the problems of low load and large investment and operation cost, and achieve the effects of increasing surface load, reducing civil construction cost and improving treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

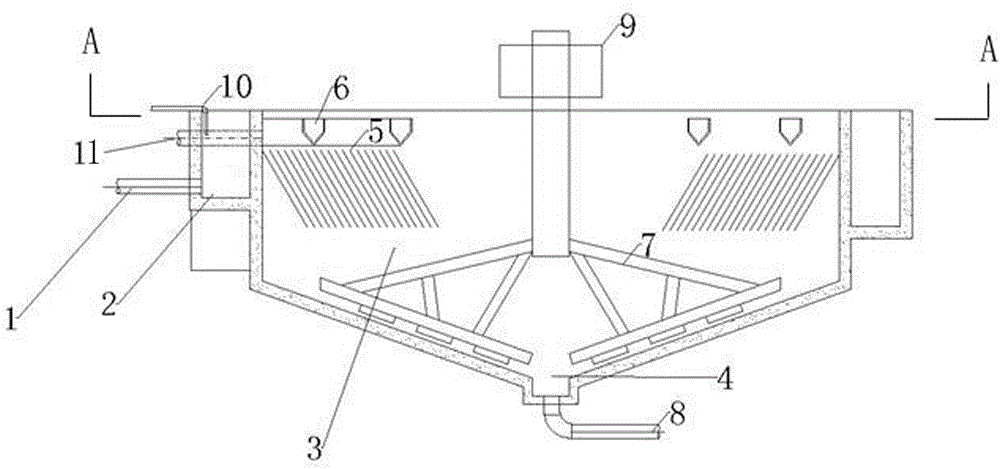

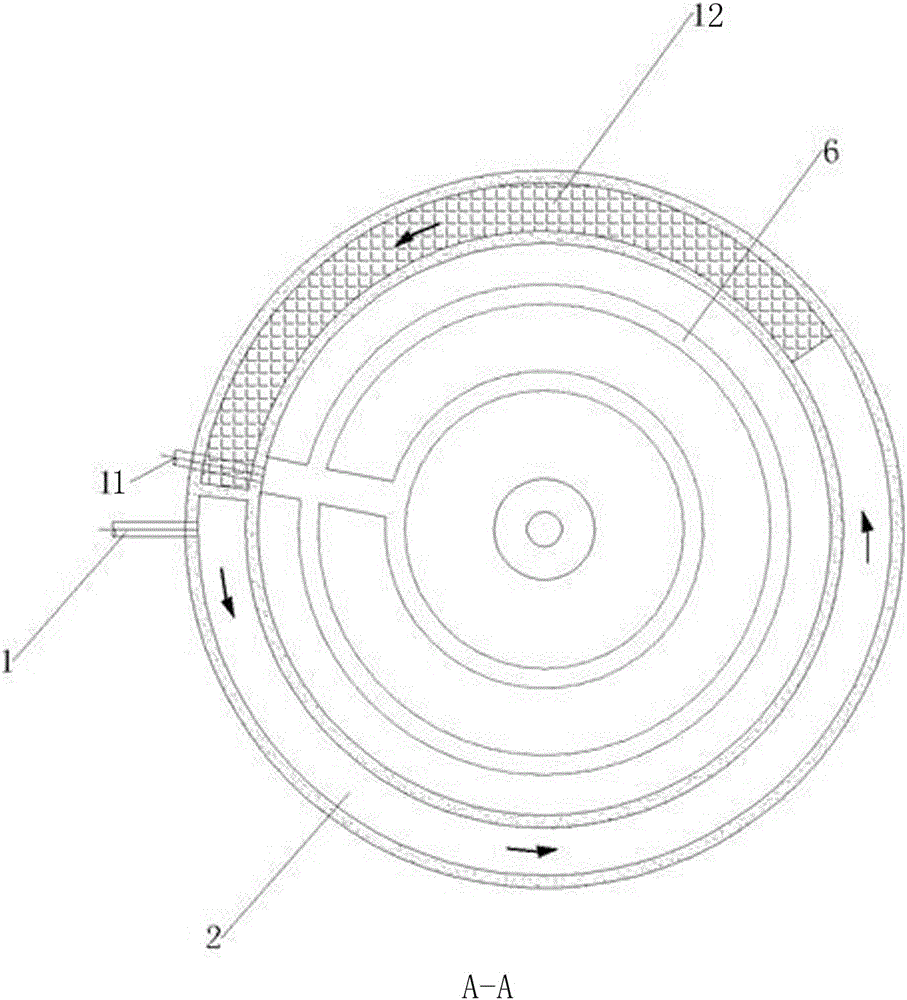

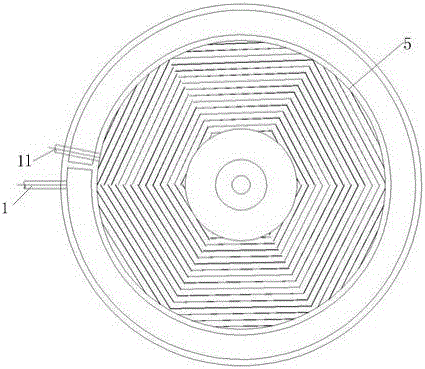

[0027] The improved enhanced phosphorus removal device of the present invention is a radial flow type secondary sedimentation tank, such as Figure 1~3 As shown, it is composed of a coagulation area, a sedimentation area, a water outlet area and a mud discharge area; the coagulation area is composed of an inlet pipe 1 and an annular coagulation corridor 2, and the water inlet pipe 1 is arranged on the side wall of the secondary sedimentation tank. Connected with the annular coagulation corridor 2, the top of the annular coagulation corridor 2 is provided with a dosing pipe 10, the slope of the bottom is 10-15%, and a perforated flower wall 12 is provided at the end 1 / 3 of the annular coagulation corridor 2;

[0028] The described settling area is adjacent to the coagulation area, and is composed of a heavy settling area 3 in the lower layer and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com