Sludge screw type direct drying device and method

A drying device and screw-type technology, applied in separation methods, sludge treatment, combined devices, etc., can solve the problems of high cost and low processing capacity, and achieve the effect of easy control, avoiding secondary pollution and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention below in conjunction with embodiment

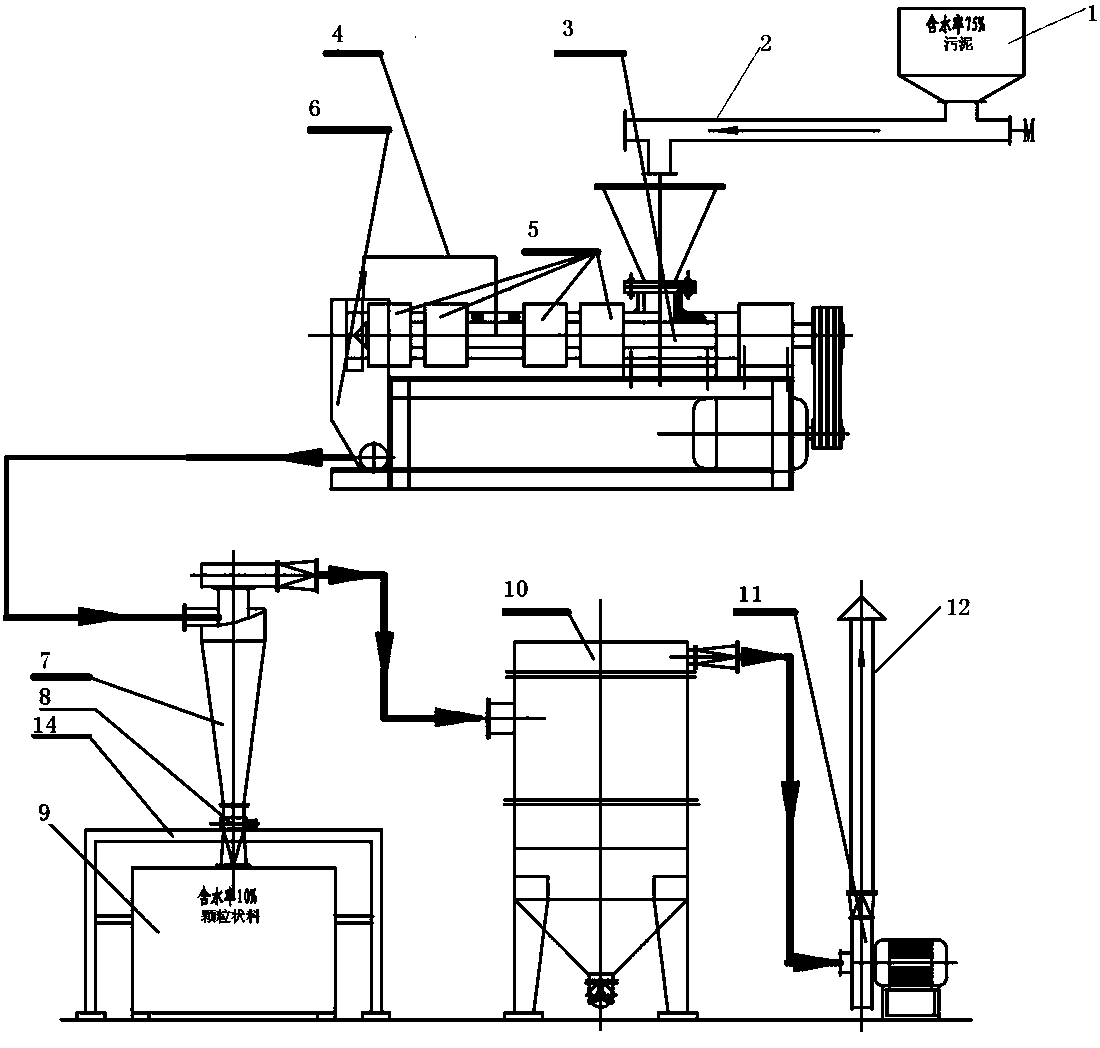

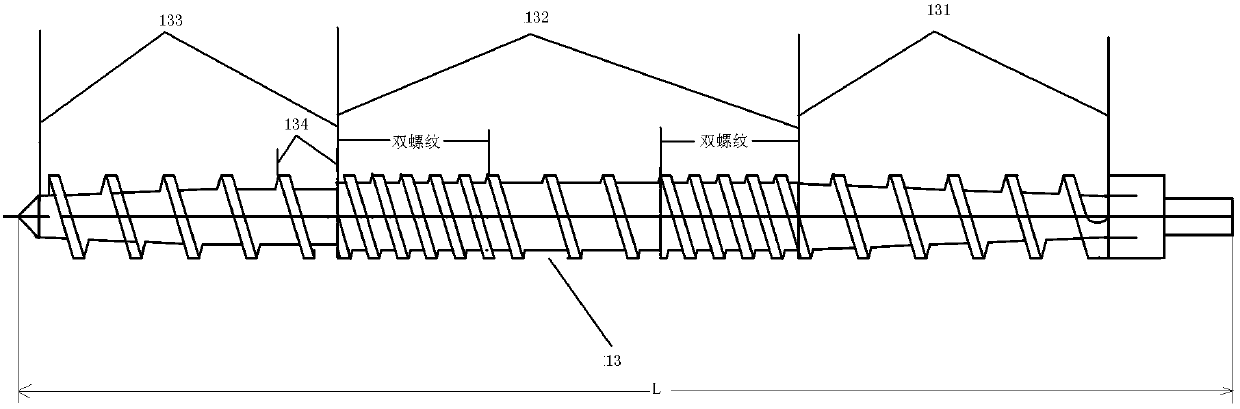

[0019] refer to figure 1 , a sludge screw-type direct drying device, including a feed hopper 1, a screw conveyor 2 is provided at the outlet of the feed hopper 1, and the discharge port of the screw conveyor 2 is fed to the screw extrusion electric heating material dryer 3 The screw extrusion electric heating material dryer 3 is wrapped with an electric heater 5, the screw 13 of the screw extrusion electric heating material dryer is driven by a motor through a pulley, and the top of the screw extrusion electric heating material dryer is equipped with a row The air pipe 4 is connected to the negative pressure collector 6, the outlet of the screw extrusion electric heating material dryer is connected to the negative pressure collector 6, and the outlet of the negative pressure collector is connected to the cyclone separator 7 through the pipeline, and the cyclone separator 7 is fixed On the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com