A track deicing device

A track and track surface technology, applied in the field of deicing equipment for traffic tracks, can solve the problems that the rail inspection vehicle cannot run on the track, the maglev train cannot be suspended on the surface, and the maglev cannot be applied, and achieves multiple social and economic benefits. Improve the ability to deal with and promote the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

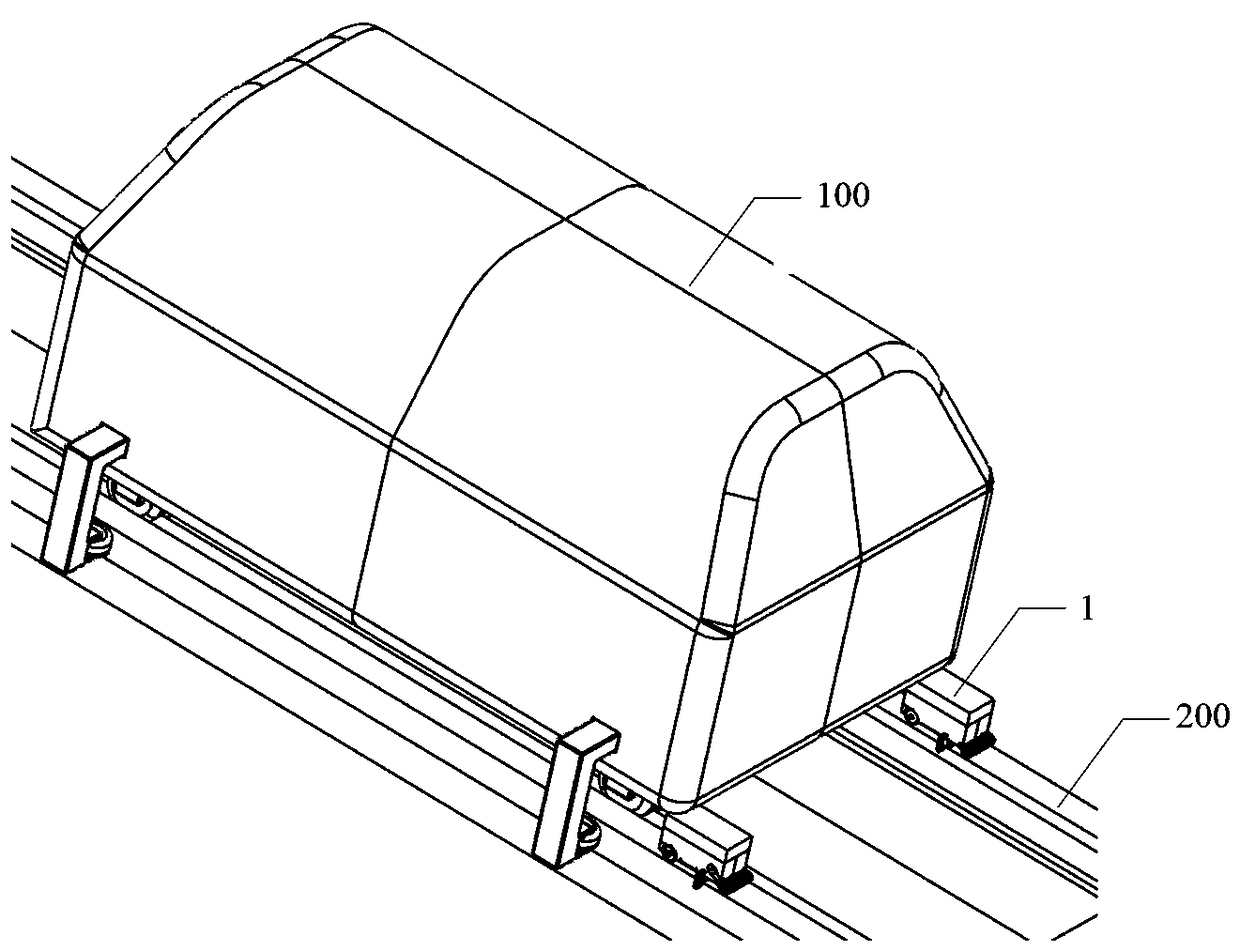

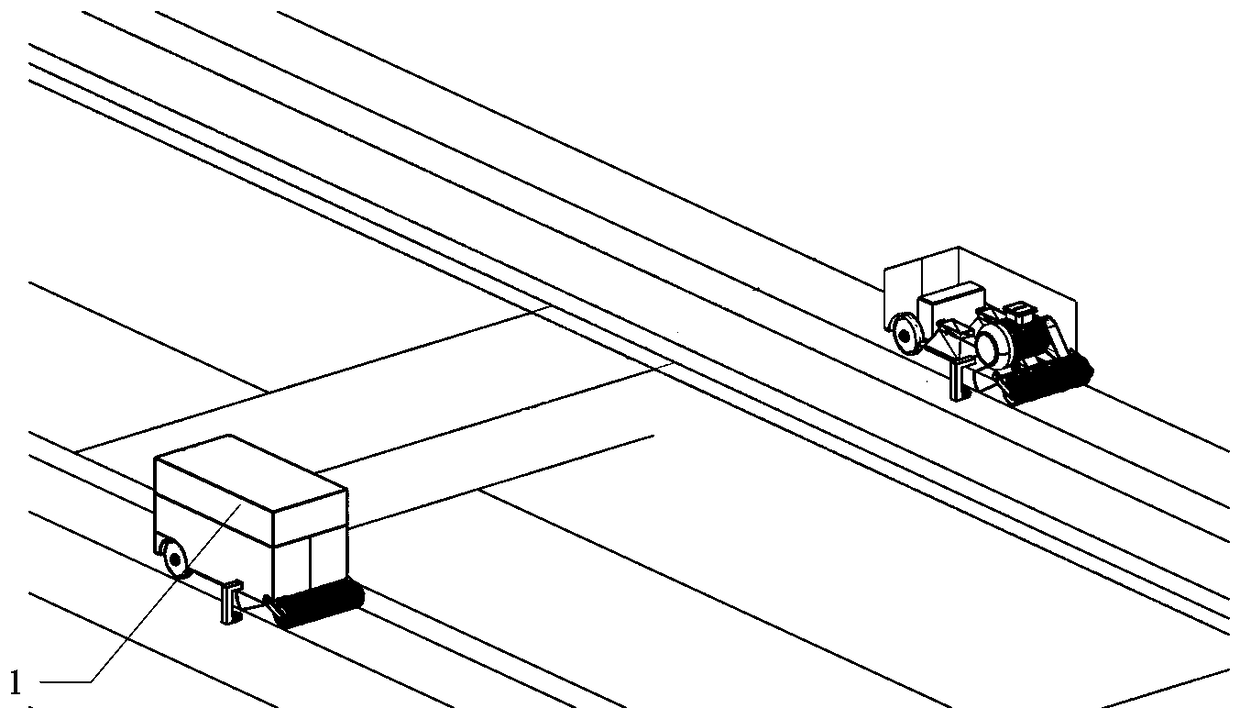

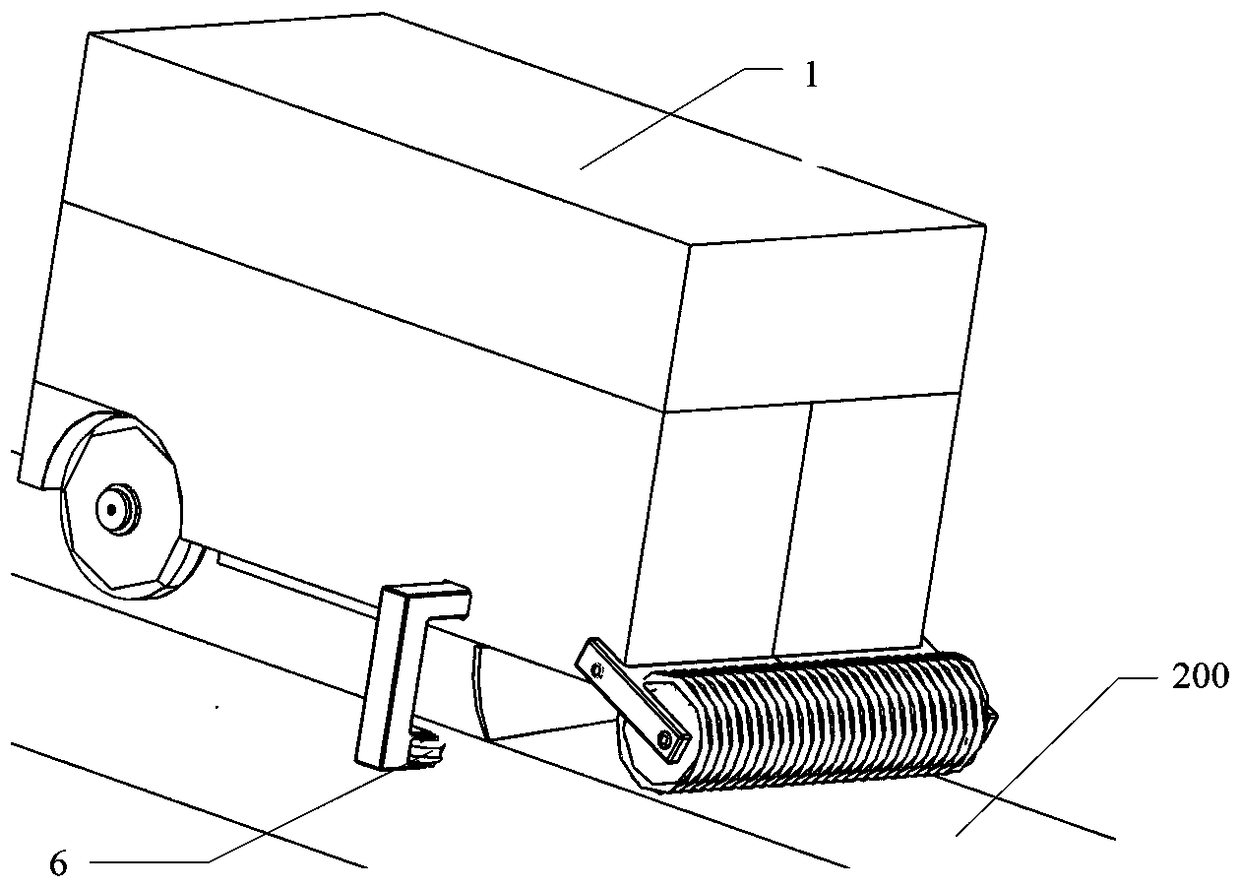

[0035] Such as Figure 1 to Figure 5 As shown, the track deicing device of the present embodiment includes two frames 1 installed on the front end of the track inspection vehicle 100, and each frame 1 is equipped with a combined deicing system for deicing the track 200 of the magnetic levitation track. Units, two sets of combined deicing units on the two racks 1 deicing the two common monorails of the track 200 respectively, and each combined deicing unit includes a mechanical crushing deicing component 2 and a cleaning deicing component 3 and the heat source deicing assembly 4, the mechanical crushing deicing assembly 2, the sweeping deicing assembly 3, and the heat source outlet 41 of the heat source deicing assembly 4 are sequentially installed on the frame 1 along the direction in which the track inspection car 100 travels, that is, the mechanical The heat source outlets 41 of the crushing deicing assembly 2, the sweeping deicing assembly 3, and the heat source deicing ass...

Embodiment 2

[0041] Such as Figure 6 As shown, the rail deicing device of the present embodiment includes four frames 1 installed on the front end of the rail inspection vehicle 100, and each frame 1 is equipped with a set of combined deicing units for deicing the rail 200 of the magnetic levitation rail A total of four sets of combined deicing units on the four racks 1 respectively deice the upper rail surface and the lower rail surface of the two F-shaped rails of the track 200. The combined deicing unit of this embodiment is the same as that of Embodiment 1.

[0042] The track deicing device is equipped with four sets of combined deicing units, which can meet the characteristics of the magnetic levitation F-shaped track, and deicing the F-shaped track in all directions without dead ends. In other embodiments, according to the rails 200 of different structures, only one or more combined de-icing units may be provided; Multiple sets of combined deicing units are divided into two groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com