A rubber damper with adjustable early stiffness

A damper, adjustable technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of increasing the volume of the anti-seismic structure, poor tensile capacity, and the risk of tearing the shock-isolation support , to achieve the effect of shortening the length and reducing the cost of isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

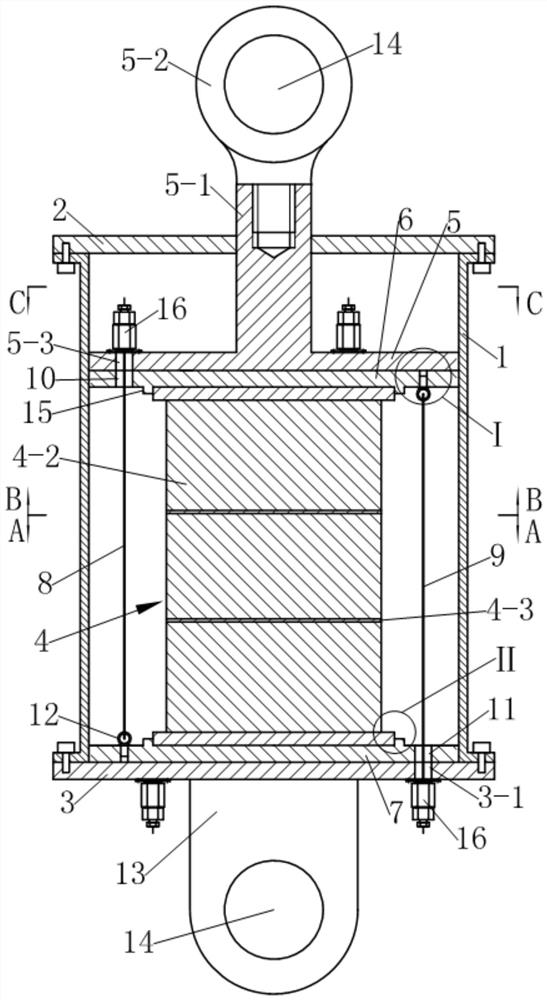

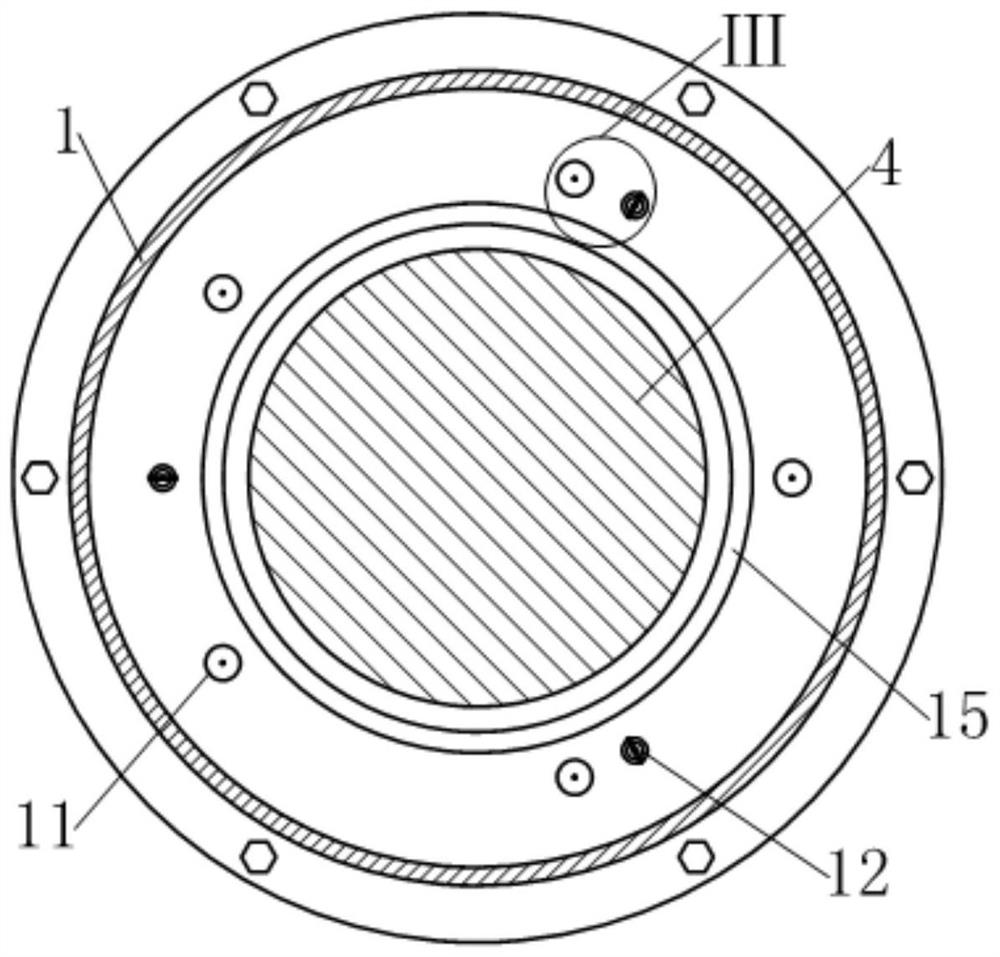

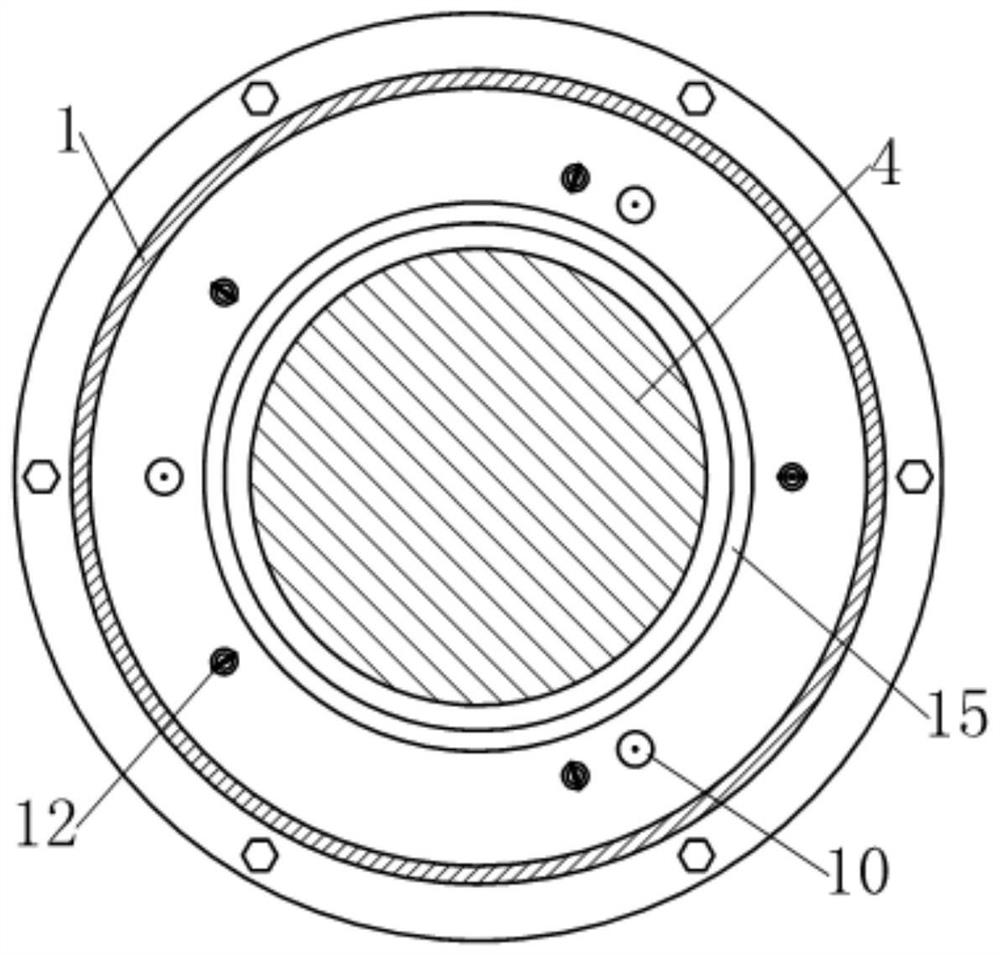

[0039] see figure 1 , the rubber damper with adjustable early stiffness in this example is an energy-dissipating device that can be used for seismic reinforcement of building structures. Cover 3, wherein, the first end cover 2 and the second end cover 3 are respectively fixedly connected to the two ends of the guide sleeve by screws. A rubber shock-isolating pad 4 is arranged in the axial direction in the guide sleeve 1, and a driving member extends from the center of the first end cover 2 into the guide sleeve 1 and presses on the rubber shock-isolating pad 4; wherein, The driving member is composed of a dynamic pressure plate 5 located at the upper end of the rubber vibration-isolating pad 4 and movingly matched with the guide sleeve 1, and a driving rod 5-1 extending upward from the upper surface of the dynamic pressure plate 5 out of the guide sleeve 1. The driving rod 5 The end of -1 located outside the guide sleeve 1 is provided with a connecting ring 5-2 with a hinged...

example 2

[0056] see Figures 14 to 18 , this example has the following differences from example 1:

[0057]Both the first group of preloaded steel cables 8 and the second group of preloaded steel cables 9 are composed of three steel cables. The number of the steel cable self-locking tensioning anchors 16 is six.

[0058] The implementation method of this example except the above is the same as Example 1.

example 3

[0060] see Figures 19-23 , the rubber damper with adjustable early stiffness in this example is a vibration isolation device (also called seismic isolation support) that can be used for vertical isolation of buildings. Compared with Example 2, this example mainly has the following differences:

[0061] 1. As a vibration-isolation support, in order to facilitate installation, the connecting lugs provided on the second end cover 3 are omitted in this example, and the second end cover 3 extends axially downward from the edge and then radially outward Extended, and the connecting bolt holes 18 are uniformly arranged at the edge, and the second end cover 3 is used as the base of the shock-isolation bearing, wherein the length extending downward axially needs to be greater than that of the self-locking tensioning anchor 16 of the steel cable high. The driving rod 5-1 of the driving member is a metal tube fixedly connected to the upper surface of the dynamic pressure plate 5 by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com