Non-load-bearing indoor wooden partition wall and construction method thereof

A construction method and internal separation technology, applied to walls, building components, buildings, etc., can solve the problems of easy fracture or damage, easy dusting of blocks, and large void ratio of blocks, so as to achieve broad application prospects, reduce pollution, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

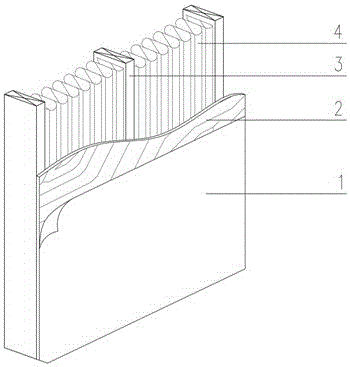

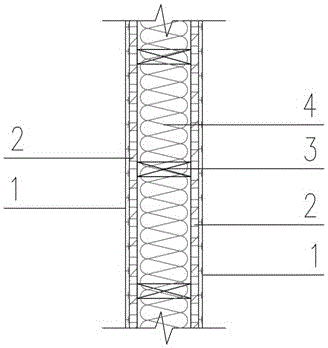

[0029] Please see attached figure 1 and attached figure 2 As shown, a non-load-bearing indoor partition wooden wall, including refractory gypsum board 1, structural plywood 2, wood frame composite wall 3 and glass fiber cotton 4; the glass fiber cotton 4 is filled in the wood frame composite wall In the cavity of the body 3, the main body of the wooden wall is formed; the structural plywood 2 is laid horizontally, and fixed on the main body of the wooden wall through 60mm galvanized screw screws, and the fire-resistant gypsum board 1 is fixed on the main body of the wooden wall through 40mm self-tapping screws The structural plywood 2 that runs through is fixedly connected to the main body of the wooden wall; the fire-resistant gypsum board 1, structural plywood 2, wood frame composite wall 3 and glass fiber cotton 4 are sequentially connected from out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com